Water-based construction waste waterproof coating and preparation method thereof

A technology of construction waste and waterproof coatings, applied in coatings and other directions, can solve problems such as insecurity, shortage of raw materials, environmental and human hazards, etc., and achieve the effects of improving performance, enhancing bonding force, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] The invention discloses a water-based construction waste waterproof coating, which is formed by mixing a powder part and a liquid part in a ratio of 6:5:

[0026] The powder part is composed of the following components in parts by weight: 65-75 parts of ground construction waste, 10-15 parts of ordinary Portland cement or white cement, 8-15 parts of heavy calcium powder, and 1 part of other modified materials ; Other modified materials in the powder part refer to general waterproof coating modified materials, including but not limited to: inorganic thickeners, talcum powder, antifungal agents or ultraviolet absorbers;

[0027] The liquid material part is composed of the following components in parts by weight: 90-95 parts of acrylic emulsion, 3-5 parts of water-based pigments, and 1-3 parts of other modified materials; the other modified materials in the liquid material part refer to Materials to adjust the properties of the emulsion, including but not limited to: defoa...

Embodiment 1

[0037] The invention discloses a water-based construction waste waterproof coating, which includes a powder part and a liquid part, specifically including the following contents:

[0038] 1. Preparation of the liquid material part of the two-component waterproof coating: 95 parts of self-made acrylic emulsion, 4 parts of water-based color paste, 0.5 part of defoamer, and 0.5 part of dispersant; stir all the materials and set aside.

[0039] 2. Preparation of the powder part of the two-component waterproof coating: 75 parts of finely ground construction waste, 15 parts of ordinary Portland cement, 9 parts of heavy calcium powder, and 1 part of bentonite; stir all the materials and set aside.

[0040] 3. Take the liquid material: powder material = 5:6, that is, take 450g of the liquid material and 550g of the powder material, then stir, and prepare samples for testing after stirring evenly.

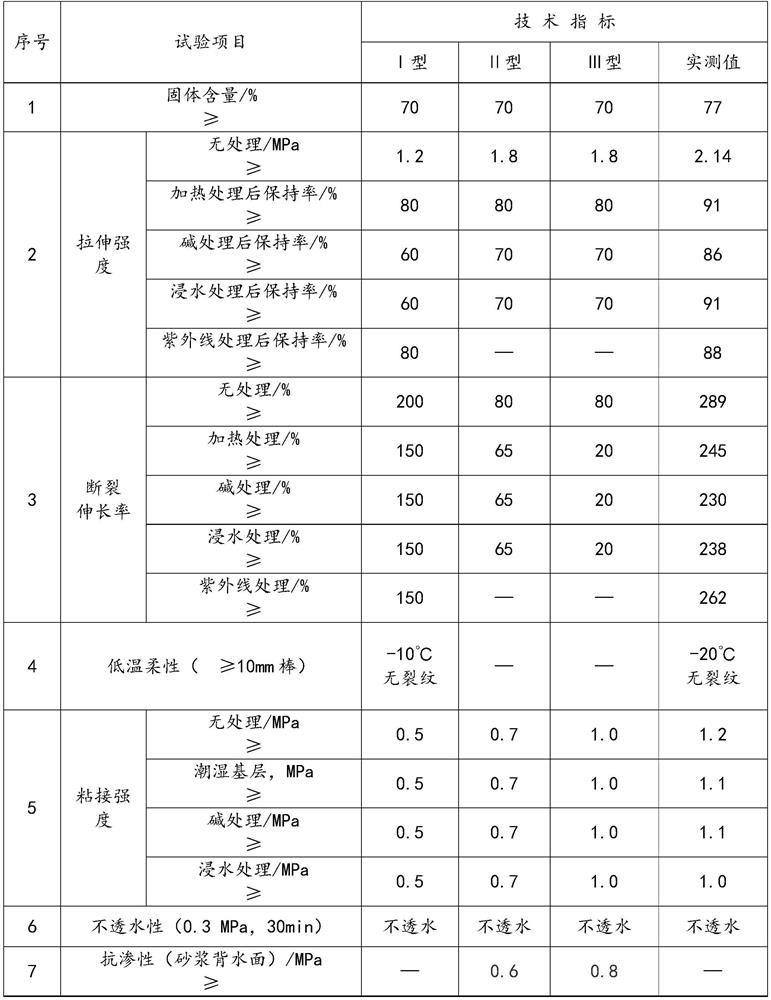

[0041] 4. Test according to the standard of GB / T23445-2009 "Polymer Cement Waterproof C...

Embodiment 2

[0045] The invention discloses a water-based construction waste waterproof coating, which includes a powder part and a liquid part, specifically including the following contents:

[0046]1. Preparation of the liquid part of the two-component waterproof coating: 95 parts of self-made acrylic emulsion, 4 parts of water-based color paste, 0.5 part of defoamer, and 0.5 part of dispersant; stir all the materials and set aside.

[0047] 2. Preparation of the powder part of the two-component waterproof coating: 70 parts of ground construction waste, 19 parts of ordinary Portland cement, 10 parts of heavy calcium powder, and 1 part of bentonite; stir all the materials and set aside.

[0048] 3. Take the liquid material: powder material = 5:6, that is, take 450g of the liquid material and 550g of the powder material, then stir, and prepare samples for testing after stirring evenly.

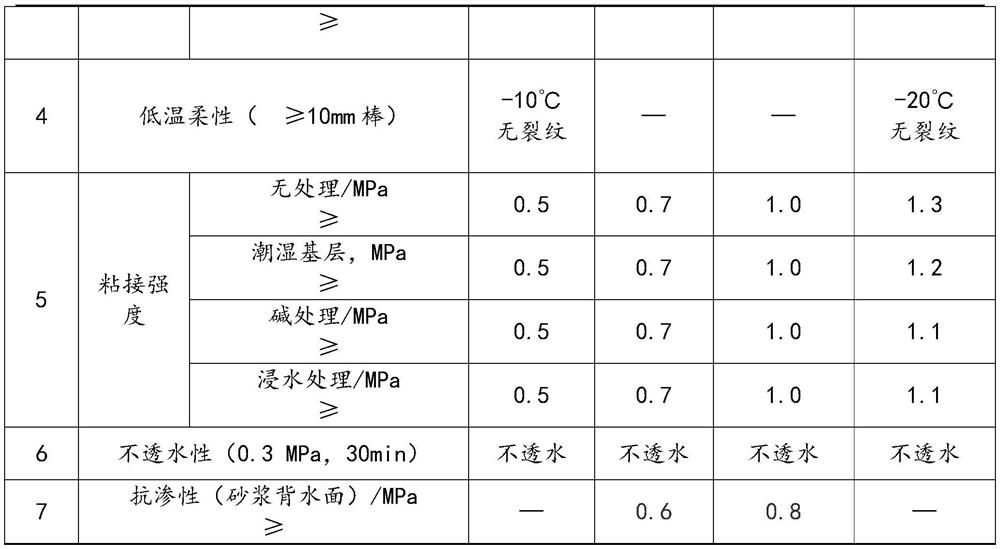

[0049] 4. Tested according to the standard of GB / T23445-2009 "Polymer Cement Waterproof Coating". The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com