A kind of graphene-based gas-sensitive material and preparation method thereof

A gas-sensing material, graphene-based technology, applied in graphene, analytical materials, chemical instruments and methods, etc., can solve the problems of general gas-sensing performance, recovery response and long recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

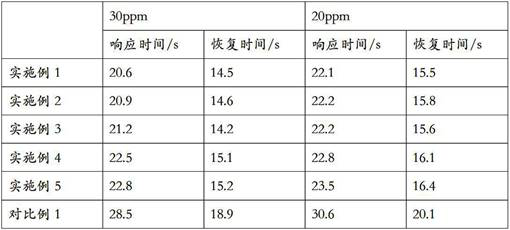

Examples

Embodiment 1

[0029] In parts by weight, take successively: 30 parts of D50 are 1# graphene oxide of 50nm, 20 parts of D50 are 2# graphene oxide of 200nm, 15 parts of D50 are 3# graphene oxide of 1200nm, import in the mixer , with a rotating speed of 1200r / min stirring and mixing for 60min, discharging, to obtain compound graphene oxide;

[0030] After mixing the compounded graphene oxide and water at a mass ratio of 1:10, and then ultrasonically stripping it for 80 minutes at an ultrasonic frequency of 180 kHz, then add metal oxide particles with a compounded graphene oxide mass of 15%. , the particle size distribution range of the metal oxide is 5-30nm, continue to ultrasonically disperse for 40min under the condition of ultrasonic frequency of 70kHz, then filter with suction to obtain a filter cake, and wash the filter cake with deionized water for 5 times, then wash the washed The filter cake was transferred to an oven, and dried to a constant weight at a temperature of 120°C to obtain ...

Embodiment 2

[0034] In parts by weight, take successively: 25 parts of D50 are 1# graphene oxide of 30nm, 18 parts of D50 are 2# graphene oxide of 180nm, 12 parts of D50 are 3# graphene oxide of 800nm, import in the mixer , stirring and mixing for 50 minutes with a rotating speed of 1000r / min, and discharging to obtain compound graphene oxide;

[0035] After mixing the compounded graphene oxide and water at a mass ratio of 1:8, and then ultrasonically stripping it for 70 minutes at an ultrasonic frequency of 160 kHz, add metal oxide particles with a compounded graphene oxide mass of 12%. , the particle size distribution range of the metal oxide particles is 10-30nm, continue to ultrasonically disperse at an ultrasonic frequency of 65kHz for 30min, then filter with suction to obtain a filter cake, wash the filter cake 4 times with deionized water, and then wash the filter cake The filter cake was transferred to an oven and dried to a constant weight at a temperature of 110°C to obtain a dry...

Embodiment 3

[0039] In parts by weight, take successively: 20 parts of D50 are 1# graphene oxide of 10nm, 15 parts of D50 are 2# graphene oxide of 100nm, 10 parts of D50 are 3# graphene oxide of 500nm, import in the mixer , with a rotating speed of 800r / min stirring and mixing for 40min, discharging, to obtain compound graphene oxide;

[0040]After mixing the compounded graphene oxide and water at a mass ratio of 1:5, and then ultrasonically stripping it for 60 minutes at an ultrasonic frequency of 100 kHz, then add metal oxide particles with a compounded graphene oxide mass of 10%. , the particle size distribution range of the metal oxide particles is 5-10nm, continue to ultrasonically disperse at an ultrasonic frequency of 60kHz for 20min, then filter with suction to obtain a filter cake, wash the filter cake 3 times with deionized water, and then wash the filter cake The filter cake was transferred to an oven and dried to a constant weight at a temperature of 100°C to obtain a dry filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com