Functional chitosan microsphere as well as preparation method and application thereof

A technology of chitosan microspheres and chitosan, which is applied in applications, pharmaceutical formulations, surgery, etc., can solve the problem of unsatisfactory hemostasis speed and effect, unable to meet the high clinical standard requirements, and the hemostasis time of hydrophobic chitosan Shorten the problem, to achieve the effect of improving hemostasis, improving the effect of flocculation and adsorption, and shortening the bleeding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

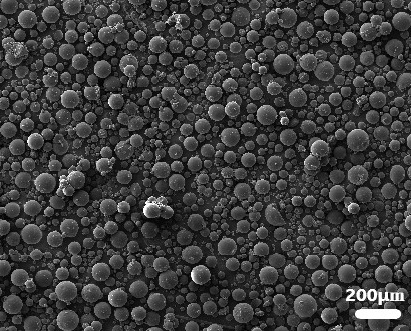

Image

Examples

Embodiment 1

[0031] A preparation method of functionalized chitosan microspheres, the concrete steps are as follows:

[0032] (1) 2g of high molecular weight chitosan (viscosity average molecular weight greater than 1.0×10 5 Da, degree of deacetylation greater than 70%) was dissolved in 80g mass concentration 2% acetic acid solution, stirred and mixed to obtain chitosan acetic acid solution, then ozone was passed into the chitosan acetic acid solution, and in a magnetic field environment, carried out Ultrasonic degradation treatment and post-treatment to obtain low molecular weight chitosan (viscosity average molecular weight less than 1.0×10 3 Da) solution;

[0033] (2) Dissolve 3g of lactobionic acid in 40g of water to obtain a lactobionic acid solution, then dissolve 1g of N,N'-dicyclohexylcarbodiimide in 30g of tetramethylethylenediamine to obtain N,N'-bicyclic Hexyl carbodiimide solution, and then lactobionic acid solution and N,N'-dicyclohexyl carbodiimide solution were dropped int...

Embodiment 2

[0041]A preparation method of functionalized chitosan microspheres, the concrete steps are as follows:

[0042] (1) 4g of high molecular weight chitosan (viscosity average molecular weight greater than 1.0×10 5 Da, degree of deacetylation greater than 70%) was dissolved in 70g mass concentration 4% acetic acid solution, stirred and mixed to obtain chitosan acetic acid solution, then ozone was introduced into the chitosan acetic acid solution, and in a magnetic field environment, carried out Ultrasonic degradation treatment and post-treatment to obtain low molecular weight chitosan (viscosity average molecular weight less than 1.0×10 3 Da) solution;

[0043] (2) Dissolve 2g of lactobionic acid in 50g of water to obtain lactobionic acid solution, then dissolve 0.8g of N,N'-dicyclohexylcarbodiimide in 40g of tetramethylethylenediamine to obtain N,N'-dicyclodiimide Cyclohexylcarbodiimide solution, and then lactobionic acid solution and N,N'-dicyclohexylcarbodiimide solution are ...

Embodiment 3

[0051] A preparation method of functionalized chitosan microspheres, the concrete steps are as follows:

[0052] (1) 3g of high molecular weight chitosan (viscosity average molecular weight greater than 1.0×10 5 Da, degree of deacetylation greater than 70%) was dissolved in 75g mass concentration 3% acetic acid solution, stirred and mixed to obtain chitosan acetic acid solution, then ozone was introduced into the chitosan acetic acid solution, and in a magnetic field environment, carried out Ultrasonic degradation treatment and post-treatment to obtain low molecular weight chitosan (viscosity average molecular weight less than 1.0×10 3 Da) solution;

[0053] (2) Dissolve 2.5g of lactobionic acid in 45g of water to obtain lactobionic acid solution, then dissolve 0.9g of N,N'-dicyclohexylcarbodiimide in 35g of tetramethylethylenediamine to obtain N,N'- Dicyclohexylcarbodiimide solution, then lactobionic acid solution and N,N'-dicyclohexylcarbodiimide solution are dropped into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com