Amide group modified hyper-crosslinked adsorption resin as well as preparation method and application thereof

A technology of ultra-high cross-linking and adsorption resin, applied in the direction of selective adsorption, chemical instruments and methods, ion exchange, etc., can solve the problems of complex synthesis route of cross-linking adsorption resin, and achieve the effect of high adsorption selectivity and high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of amide group modified ultra-high cross-linked adsorption resin, comprising the following steps:

[0039] First, add the hydrophilic network monomer N,N'-(4,4'-methylenediphenyl) bismaleimide and the hydrophobic network monomer di Vinylbenzene, and an appropriate amount of initiator azobisisobutyronitrile; then add 100mL dimethylformamide into the three-necked flask, stir and dissolve at room temperature, and then heat up to 80°C after bubbling nitrogen for 0.5h, and keep the reaction for 24h. get the reaction product;

[0040]Then, the above reaction product was Soxhlet-extracted with tetrahydrofuran for 24 hours, rinsed and soaked in water for 12 hours until odorless; finally, vacuum-dried at 80°C for 24 hours to obtain an amide group-modified ultra-high cross-linked adsorption resin. Its yield was 99.3%.

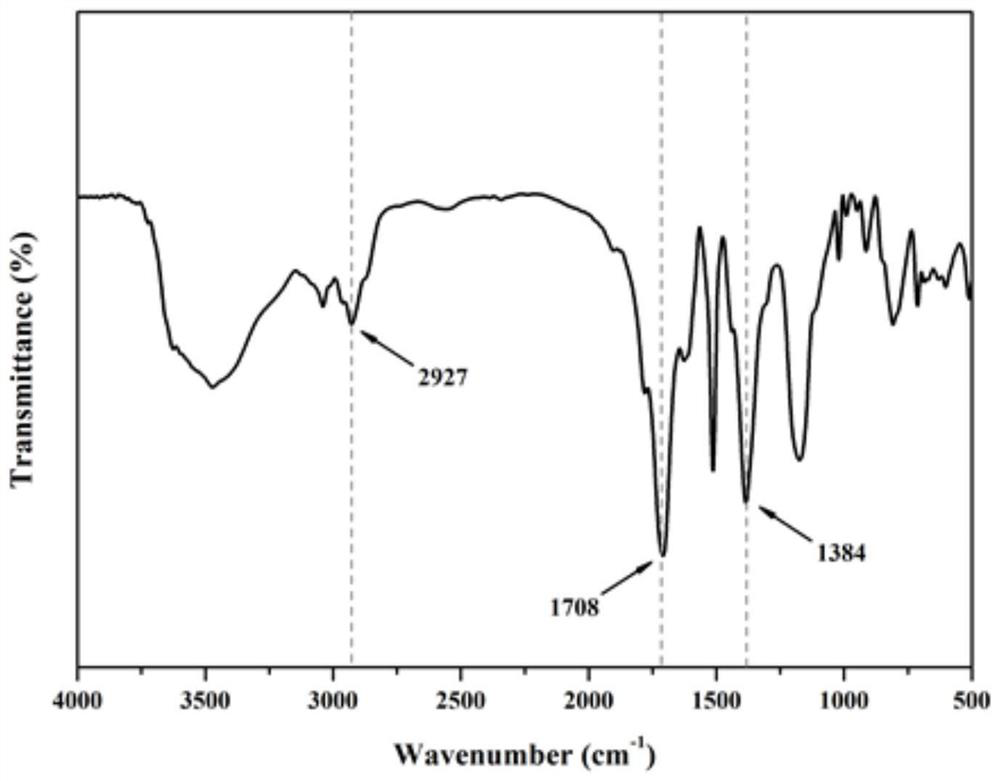

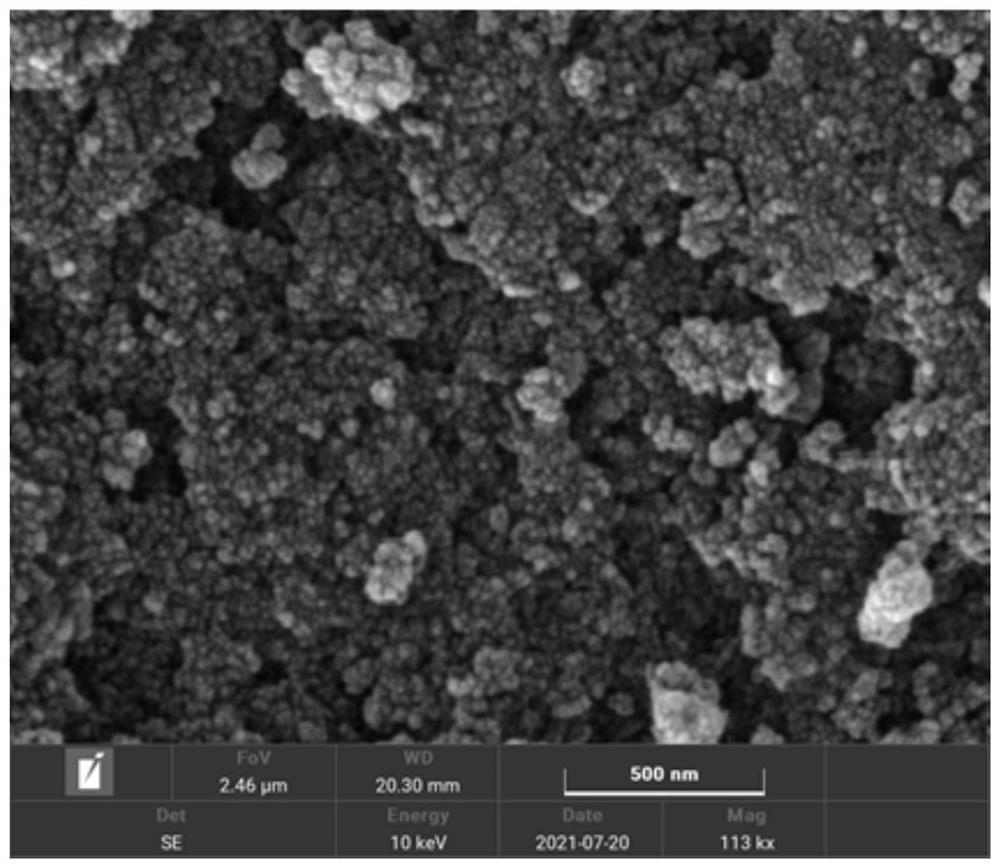

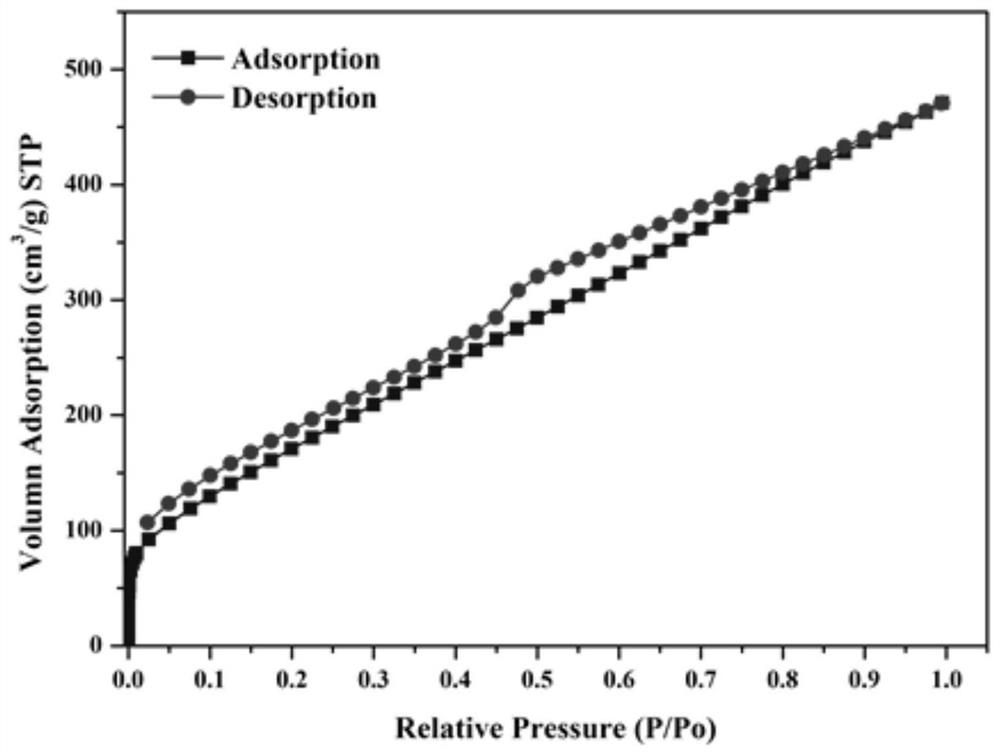

[0041] The specific surface area of the amide group-modified ultra-high cross-linked adsorption resin prepared by the above preparation m...

Embodiment 2

[0043] In Example 2, the molar ratio of the hydrophilic network monomer to the hydrophobic network monomer was 1:1.5, and the others were the same as in Example 1; the yield of the obtained amide group-modified ultra-high cross-linked adsorption resin was 85.6%.

Embodiment 3

[0044] In Example 3, the molar ratio of the hydrophilic network monomer to the hydrophobic network monomer was 1:0.33, and the others were the same as in Example 1; the yield of the obtained amide group-modified ultra-high cross-linked adsorption resin was 76.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap