Single crystal diamond seed crystal and sample holder welding method

A technology of single crystal diamond and welding method, which is applied in the field of material welding, and can solve the problems of seed crystal drift, heat conduction and defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0012] Specific embodiment one: the welding method of the single crystal diamond seed crystal and the sample holder in this embodiment is implemented according to the following steps:

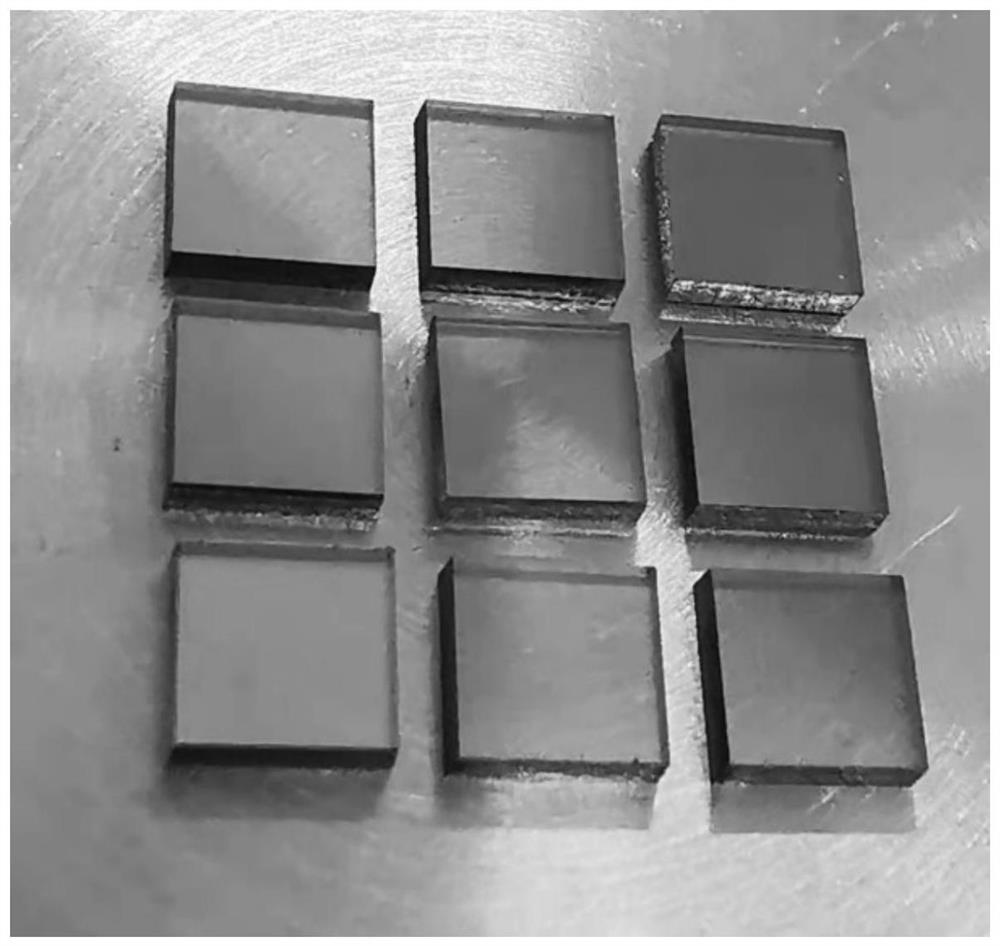

[0013] 1. Surface pretreatment: Place multiple single crystal diamond seed crystals that have been ultrasonically cleaned with the bottom facing up on the substrate of the plasma cleaning machine, and then perform surface pretreatment with oxygen plasma to obtain pretreated single crystal diamond seed crystals;

[0014] 2. Coating: Place a plurality of pretreated single crystal diamond seeds on the coating substrate, with the surface treated by oxygen plasma facing up, and put it into the magnetron sputtering coating equipment, and select gold (purity is 99.99%) As a target material, a gold layer is then plated on the surface of the single crystal diamond seed crystal to obtain the coated single crystal diamond seed crystal;

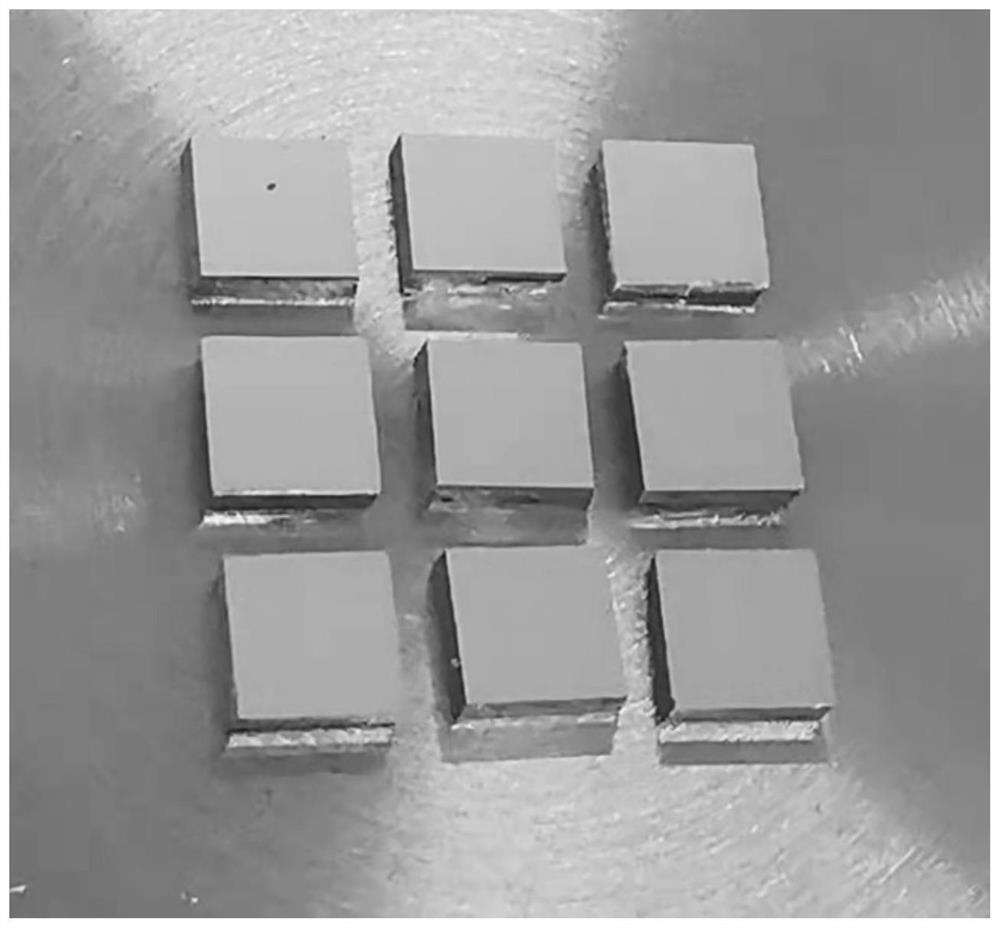

[0015] 3. In-situ welding: Place multiple coated single crystal diam...

specific Embodiment approach 2

[0017] Embodiment 2: This embodiment differs from Embodiment 1 in that the distance between adjacent single crystal diamond seed crystals in step 1 is 0.5-2 mm.

[0018] The distance between the single crystal diamond seed crystals in this embodiment ensures that the seed crystals do not interfere with each other during the plasma pretreatment and increases the number of placements for one treatment.

specific Embodiment approach 3

[0019] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, oxygen plasma surface pretreatment is carried out under the conditions of oxygen flow rate of 30 sccm, power of 600 W, and air pressure of 1 kPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com