Magnesium and aluminum suspension and preparation process thereof

A preparation process, a technology of magnesium and aluminum, applied in the directions of liquid transportation, emulsion transportation, aluminum/calcium/magnesium active ingredients, etc., can solve problems such as no suspension found, achieve good uniformity, low production cost, increase The effect of compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Table 1

[0040] Name of raw material Weight (g) Proportion wt% Magnesium plus aluminum 5 5 hypromellose 0.05 0.05 colloidal microcrystalline cellulose 0.5 0.5 carrageenan 0.3 0.3 Sorbitol 14 (concentration 70wt%) 14 Simethicone Lotion 0.5 0.5 Dihydrochalcone 0.5 0.5 Chlorhexidine acetate 0.05 0.05 orange flavor 0.5 0.5 purified water 78.6 78.6

[0041] Preparation Process:

[0042] Step 1. Weigh each component according to the formula in Table 1.

[0043] Step 2. Add the colloidal microcrystalline cellulose to 25 mL of purified water and stir, and then pass through a high-shear emulsifier for high-shear operation for 10 minutes to obtain a colloidal microcrystalline cellulose dispersion, which is ready for use.

[0044] Step 3. Add hypromellose and carrageenan into 30 mL of boiling water, stir for 1 hour to fully swell, and obtain a mixed solution of hypromellose and carrageenan, ...

Embodiment 2

[0051] Table 2

[0052] Name of raw material Weight (g) Proportion wt% Magnesium plus aluminum 5 5 hypromellose 0.02 0.02 colloidal microcrystalline cellulose 0.8 0.8 carrageenan 0.3 0.3 Sorbitol 12 (concentration 60wt%) 12 Simethicone Lotion 0.5 0.5 Dihydrochalcone 0.5 0.5 Chlorhexidine acetate 0.05 0.05 orange flavor 0.5 0.5 purified water 80.33 80.33

[0053] Preparation Process:

[0054] Step 1. Weigh each component according to the formula in Table 2.

[0055] Step 2. Add the colloidal microcrystalline cellulose to 25 mL of purified water and stir, and then pass through a high-shear emulsifier for high-shear operation for 10 minutes to obtain a colloidal microcrystalline cellulose dispersion, which is ready for use.

[0056] Step 3. Add hypromellose and carrageenan into 25 mL of boiling water, stir for 1 hour to fully swell, and obtain a mixed solution of hypromellose and carrageenan...

Embodiment 3

[0063] table 3

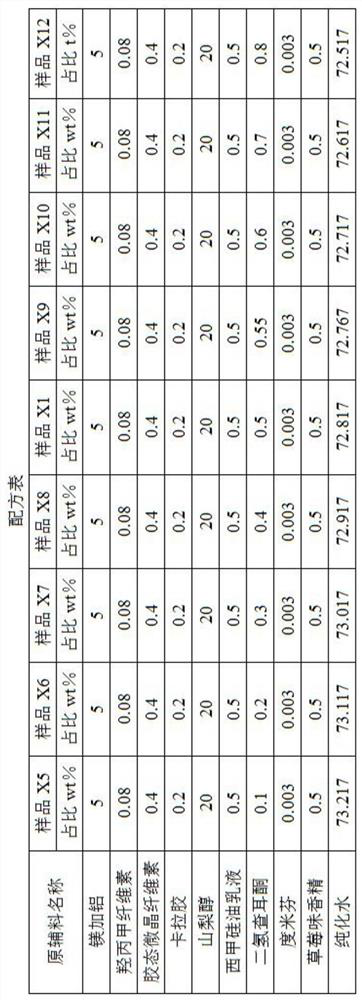

[0064] Name of raw material Weight (g) Proportion wt% Magnesium plus aluminum 5 5 hypromellose 0.08 0.08 colloidal microcrystalline cellulose 0.4 0.4 carrageenan 0.2 0.2 Sorbitol 20 (concentration 70wt%) 20 Simethicone Lotion 0.5 0.5 Dihydrochalcone 0.5 0.5 Domiphene 0.003 0.003 strawberry flavor 0.5 0.5 purified water 72.817 72.817

[0065] Preparation Process:

[0066] Step 1. Weigh each component according to the formula in Table 3.

[0067] Step 2. Add the colloidal microcrystalline cellulose to 25 mL of purified water and stir, and then pass through a high-shear emulsifier for high-shear operation for 10 minutes to obtain a colloidal microcrystalline cellulose dispersion, which is ready for use.

[0068] Step 3. Add hypromellose and carrageenan into 25 mL of boiling water, stir for 1 hour to fully swell, and obtain a mixed solution of hypromellose and carrageenan, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com