Grinding wheel for grinding difficult-to-machine materials and preparation method

A difficult-to-machine and grinding wheel technology, applied in metal processing equipment, grinding/polishing equipment, grinding devices, etc., can solve the problems of less dressing times, low processing efficiency, high adaptability of difficult-to-machine materials, etc., to achieve the solution of difficult-to-machine , to overcome the effect of serious wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

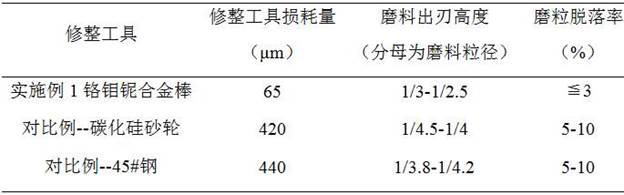

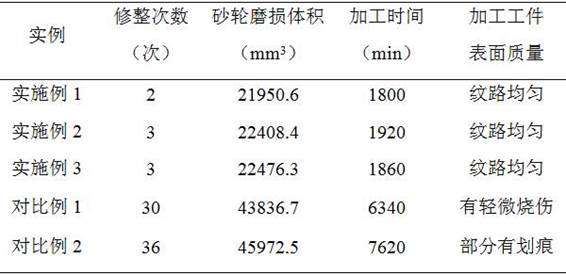

Embodiment 1

[0020] A grinding wheel for grinding difficult-to-machine materials, the abrasive layer of which is composed of the following raw materials in parts by mass: 38 parts of mixed abrasive, 6.5 parts of abrasive surface modifier, 40.5 parts of bonding agent, and 15 parts of kyanite fiber. The kyanite fiber has a diameter of 3 microns and a length of 20 microns.

[0021] The preparation method of the above-mentioned grinding wheel for grinding difficult-to-machine materials comprises mixing the mixed abrasive, abrasive surface modifier and kyanite fiber in proportion, adding a binder and mixing to obtain a molding material, which is hot-pressed (the process parameter is : Hot pressing temperature 230°C, hot pressing pressure 10MPa, pressing time 50min), sintering (process parameters: sintering temperature 230°C, sintering time 12h), turning and grinding machine processing and dressing to obtain the finished grinding wheel; the dressing is specifically:

[0022] Dressing method: use...

Embodiment 2

[0024] A grinding wheel for grinding difficult-to-machine materials, the abrasive layer of which is composed of the following raw materials in parts by mass: 30 parts of mixed abrasive, 5 parts of abrasive surface modifier, 35 parts of bonding agent, and 30 parts of kyanite fiber. The kyanite fiber has a diameter of 1 micron and a length of 5 microns.

[0025] The preparation method of above-mentioned difficult-to-machine material grinding wheel, described trimming is specifically as follows, other with reference to embodiment 1:

[0026] Dressing method: use a chromium-molybdenum-niobium alloy ring with a hardness of HRC38 as a dressing tool, the speed of the grinding wheel to be repaired is 1150rpm, and the speed of the dressing tool is 290rpm; The single feed amount is 0.005mm, and the trimming amount is 0.12mm, and the grinding wheel is trimmed and sharpened.

Embodiment 3

[0028] A grinding wheel for grinding difficult-to-machine materials, the abrasive layer of which is composed of the following raw materials in parts by mass: 25 parts of mixed abrasive, 4 parts of abrasive surface modifier, 38 parts of bonding agent, and 33 parts of kyanite fiber. The kyanite fiber has a diameter of 2 microns and a length of 10 microns.

[0029] The preparation method of above-mentioned difficult-to-machine material grinding wheel, described trimming is specifically as follows, other with reference to embodiment 1:

[0030] Dressing method: Use chromium-molybdenum-niobium alloy rods with a hardness of HRC45 as the dressing tool, the speed of the grinding wheel to be repaired is 1440rpm, and the speed of the dressing tool is 480rpm; The single feed amount is 0.005mm, and the trimming amount is 0.10mm, and the grinding wheel is trimmed and sharpened.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com