Alterant for high-chromium cast iron and preparation method thereof

A technology of high-chromium cast iron and modifier, applied in the field of metal materials and processing, can solve the problems such as the effect and stability of metamorphism are yet to be studied, the mechanism of metamorphism is not described in detail, and the effects of metamorphism are not the same. Combined properties, improved wear resistance and toughness, ease of absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

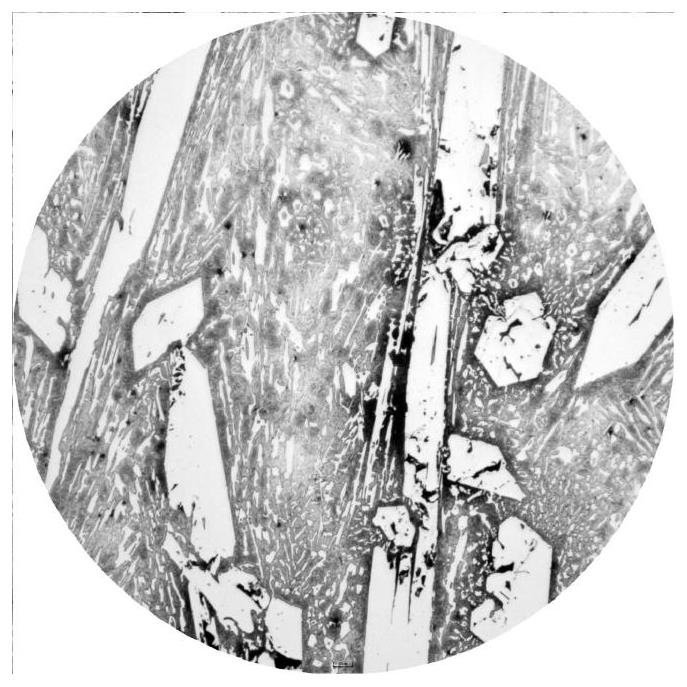

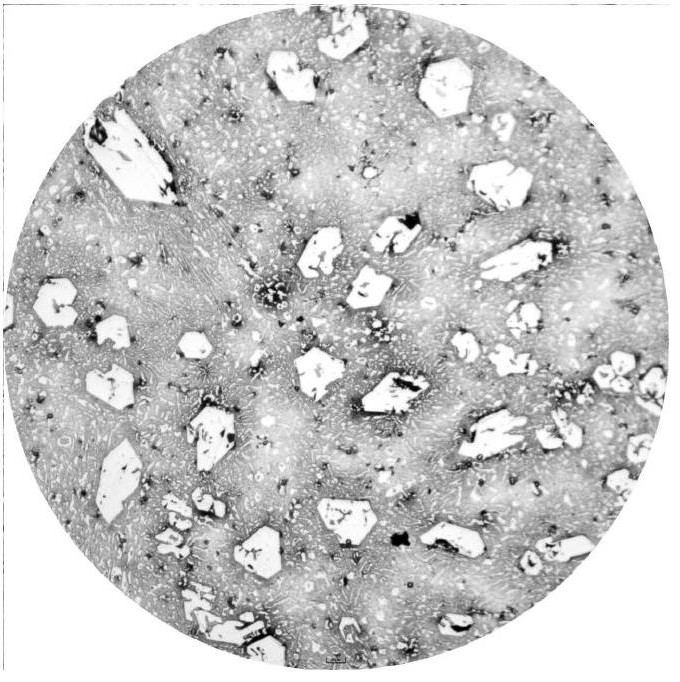

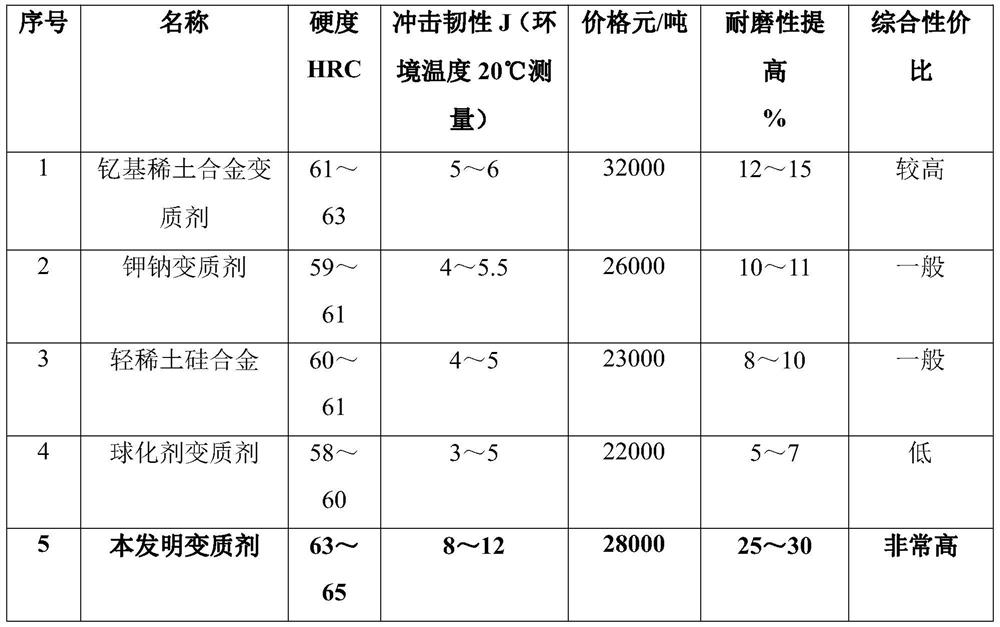

Image

Examples

Embodiment 1

[0041] Preparation of modifier for high chromium cast iron:

[0042] (1) The first step is to prepare raw materials.

[0043] Weigh electrolytic chromium, stainless steel 304 and 316L, nickel iron, electrolytic manganese, electrolytic vanadium, 1# zinc ingot, electrolytic copper, borax, chromium nitride, zirconium iron, niobium iron, electrolytic cobalt, molybdenum iron, according to the final chemical composition range For: Cr: 71%, Ni: 10%, Mo: 1.3%, Mn: 1.1%, V: 0.2%, Zn: 0.7%, Cu: 0.8%, B: 0.18%, N: 0.15%, Zr: 0.15 %, Nb: 0.26%, Co: 0.15%, respectively weigh certain mass fractions for batching.

[0044] (2) The second step is raw material pretreatment.

[0045] Mix the raw materials weighed in the first step evenly, put them into a box furnace, and keep them warm at 300°C. The holding time is controlled for 2 to 6 hours. The holding time is adjusted according to the amount of charge, and the charge is less than 500kg. , keep warm for 2 hours, thoroughly dry the moisture...

Embodiment 2

[0060] Preparation of modifier for high chromium cast iron:

[0061] (1) The first step is to prepare raw materials.

[0062] Weigh electrolytic chromium, stainless steel 304 and 316L, nickel iron, electrolytic manganese, electrolytic vanadium, 1# zinc ingot, electrolytic copper, borax, chromium nitride, zirconium iron, niobium iron, electrolytic cobalt, molybdenum iron, according to the final chemical composition range For: Cr: 75%, Ni: 11.5%, Mo: 01.3%, Mn: 1.45%, V: 0.28%, Zn: 1.2%, Cu: 1.0%, B: 0.25%, N: 0.2%, Zr: 0.2 %, Nb: 0.3%, Co: 0.2%, weigh certain mass fractions respectively for batching.

[0063] (2) The second step is raw material pretreatment.

[0064] Mix the raw materials weighed in the first step evenly, put them into a box-type furnace, and keep them warm at 260°C. The holding time is controlled for 2 to 6 hours. The holding time is adjusted according to the amount of charge, and the charge is 500kg. ~1000kg heat preservation for 3~4 hours. Thoroughly dry...

Embodiment 3

[0078] Preparation of modifier for high chromium cast iron:

[0079] (1) The first step is to prepare raw materials.

[0080] Weigh electrolytic chromium, stainless steel 304 and 316L, nickel iron, electrolytic manganese, electrolytic vanadium, 1# zinc ingot, electrolytic copper, borax, chromium nitride, zirconium iron, niobium iron, electrolytic cobalt, molybdenum iron, according to the final chemical composition range For: Cr: 72.5%, Ni: 11%, Mo: 1.2%, Mn: 1.25%, V: 0.25%, Zn: 0.9%, Cu: 0.9%, B: 0.20%, N: 0.17%, Zr: 0.17 %, Nb: 0.28%, Co: 0.17%, respectively weigh certain mass fractions for batching.

[0081] (2) The second step is raw material pretreatment.

[0082] Mix the raw materials weighed in the first step evenly, put them into a box furnace, and keep them warm at 380°C. The holding time is controlled for 2 to 6 hours. The holding time is adjusted according to the amount of charge, and the charge is more than 1000kg. Keep warm for 4-6 hours. Thoroughly dry the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com