Method for synthesizing n-butyl isocyanate by gas phase method

A technology of n-butyl isocyanate and gas phase method, applied in the preparation of isocyanate derivatives, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as complicated post-treatment processes, and achieve high reaction conversion and selectivity. , the effect of reducing costs and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

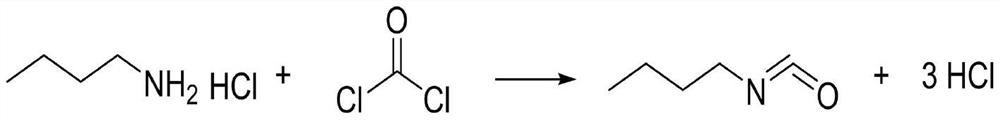

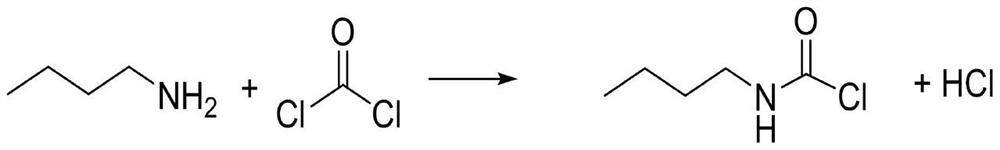

Method used

Image

Examples

Embodiment 1

[0038] Preheat n-butylamine to 110°C, preheat phosgene to 90°C, pass phosgene and n-butylamine into the fixed bed according to the molar ratio of 3:1 to react. The catalyst in the fixed bed is a ceramic filler containing 1% zinc chloride, the reaction temperature in the fixed bed is 140°C, the reaction pressure is 2.0MPa, and the residence time is 30s. After cooling, degassing and rectification, the discharged material has a FNC content of 99.5% and a yield of 72.3%.

Embodiment 2

[0040] Preheat n-butylamine to 80°C, preheat phosgene to 110°C, pass phosgene and n-butylamine into the fixed bed according to the molar ratio of 5:1 to react. The catalyst in the fixed bed is a ceramic filler containing 2% magnesium chloride, the reaction temperature in the fixed bed is 180°C, the reaction pressure is 3.0MPa, and the residence time is 60s. After cooling, degassing and rectification, the discharged material has a FNC content of 99.7% and a yield of 75.8%.

Embodiment 3

[0042] Preheat n-butylamine to 120°C, preheat phosgene to 100°C, pass phosgene and n-butylamine into the fixed bed for reaction according to the molar ratio of 1.5:1. The catalyst in the fixed bed is a ceramic filler containing 5% zinc chloride, the reaction temperature in the fixed bed is 200°C, the reaction pressure is 5.0MPa, and the residence time is 100s. After cooling, degassing and rectification, the discharged material has a FNC content of 99.6% and a yield of 58.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com