Heat-detachable polyurethane hot melt adhesive, preparation raw materials, and preparation method and bonding method of heat-detachable polyurethane hot melt adhesive

A technology of polyurethane hot-melt adhesive and raw materials, applied in the field of polyurethane adhesives, can solve the problem of non-removable polyurethane hot-melt adhesive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

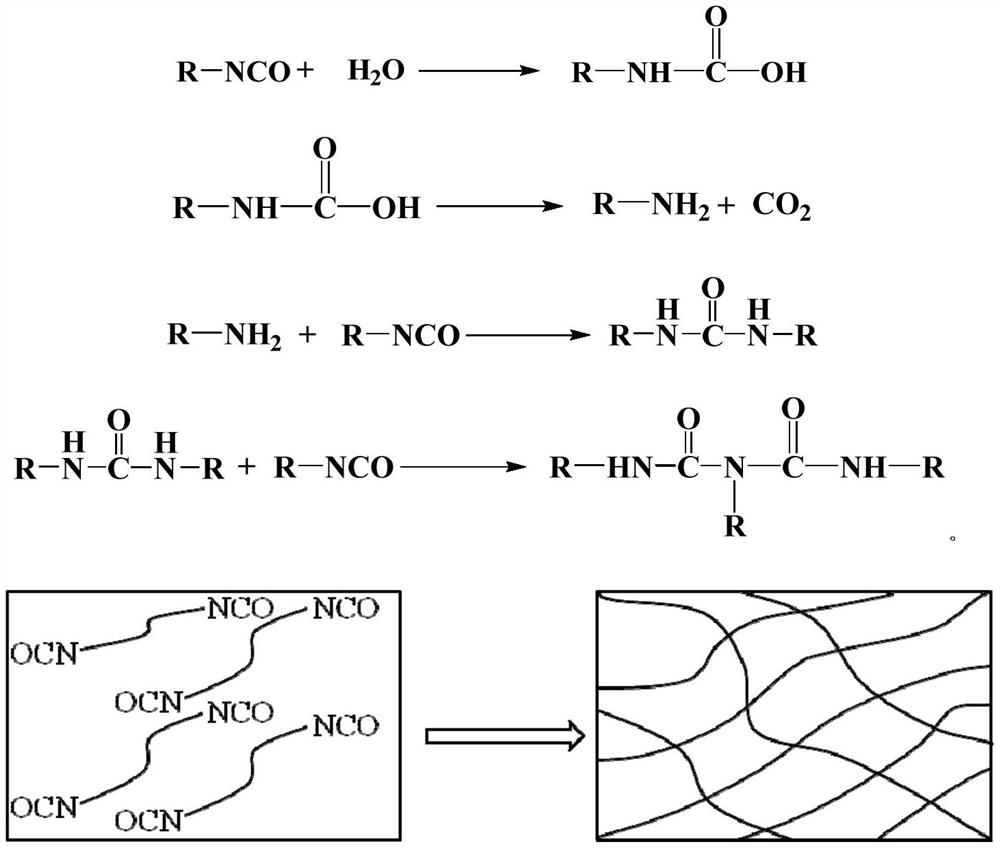

Method used

Image

Examples

preparation example Construction

[0025] The raw materials for the preparation of the detachable polyurethane hot melt adhesive provided by the present invention contain polyol compounds, polyisocyanate compounds, sulfur-containing compounds and catalyst. Specifically, the mass ratio of the polyisocyanate compound to the polyol compound is (35-120):100, such as 35:100, 40:100, 45:100, 50:100, 55:100, 60:100, 65 :100, 70:100, 75:100, 80:100, 85:100, 90:100, 95:100, 100:100, 105:100, 110:100, 115:100, 120:100, etc. The mass ratio of the sulfur-containing compound to the polyol compound is (2.5-150):100, such as 2.5:100, 5:100, 10:100, 15:100, 20:100, 25:100, 30:100, 35:100, 40:100, 45:100, 50:100, 55:100, 60:100, 65:100, 70:100, 75:100, 80:100, 85:100, 90:100, 95: 100, 100:100, 105:100, 110:100, 115:100, 120:100, 125:100, 130:100, 135:100, 140:100, 145:100, 150:100, etc. The mass ratio of the catalyst to the polyol compound is (0.1-2):100, such as 0.1:100, 0.2:100, 0.5:100, 0.8:100, 1:100, 1.2:100, 1.5:100, 1...

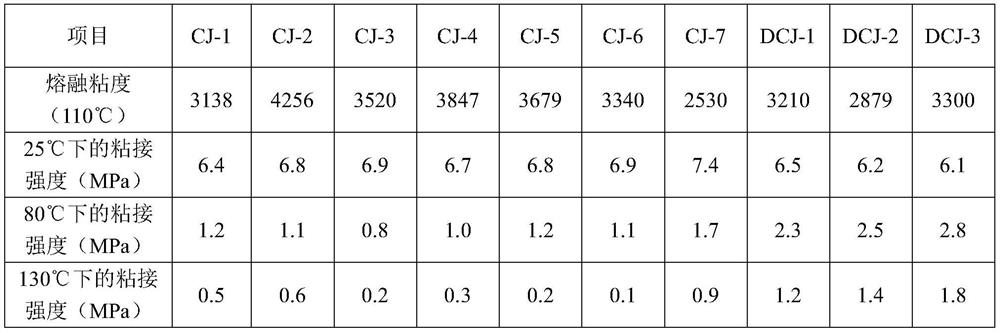

Embodiment 1

[0038] In parts by weight, 54.5 parts of polycaprolactone diol with a number average molecular weight of 1,000, 2.8 parts of 2-hydroxyethyl disulfide , 0.1 part of 2,2-dimorpholino diethyl ether was added to the reaction flask, heated to 110°C, and vacuum dehydrated for 2 hours under the stirring condition of 150r / min; then cooled to 80°C, and 24.5 parts of 4,4 '-Diphenylmethane diisocyanate (MDI) was reacted for 2 hours at a stirring speed of 150r / min under vacuum conditions, and then discharged to obtain a removable polyurethane hot melt adhesive (referred to as CJ-1), which was stored in a vacuum seal.

Embodiment 2

[0040] In parts by weight, 44.0 parts of polybutylene adipate diol with a number average molecular weight of 2000, 22.0 parts of polytetrahydrofuran ether diol with a number average molecular weight of 1000, 6.8 parts of 2-hydroxyethyl disulfide, 0.5 Add 2 parts of dibutyltin dilaurate into the reaction flask, heat to 120°C, and vacuum dehydrate for 2h under 150r / min stirring condition; then cool down to 80°C, add 26.6 parts of hexamethylene diisocyanate (HDI), and Under the conditions, react at a stirring speed of 150r / min for 2h and discharge to obtain a detachable polyurethane hot-melt adhesive (referred to as CJ-2), which is stored in a vacuum seal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com