Preparation method for co-production of biochar from malus micromalus makino high-calcium beverage

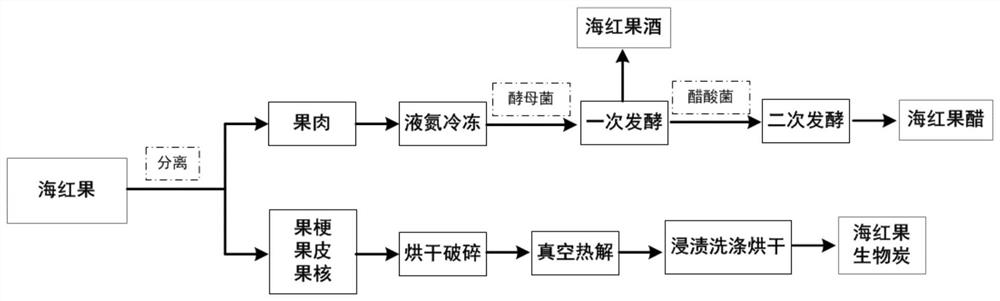

The technology of sea red fruit and biochar is applied in the field of preparation of sea red fruit high-calcium beverage co-producing biochar, which can solve the problems of large processing waste, single processing part of sea red fruit, waste of resources, etc., and achieves no sourness and bitterness. Good taste and look, reduced waste and waste emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Preparation of fruit wine: select the sea red fruit (calcium content 62.46mg / g) with full fruit, no rot, and no wormholes, clean it, remove impurities, remove stems, peel, and pit, put it in a container, and pour it into a solid-to-liquid ratio of 1: 5 ℃ of liquid nitrogen, so that the sea red fruit is fully frozen for 5 minutes, and then fully crushed into powder with a pulverizer, and stored in a freezer. Take liquid nitrogen to treat the crushed sea red fruit, add water to dilute 20 times (solid-to-liquid ratio 1:20) to adjust the sugar content, add 0.5% pectinase, keep warm at 45°C for 5 hours, and then filter and clarify. rejoin SO 2 , the concentration is 30mg / kg, put it into a 1.21MPa high-temperature sterilization pot for 20min for sterilization. Take it out, cool it to room temperature, inoculate it with activated high-efficiency Saccharomyces Angelica, and ferment it at 28°C for 2 days. Filtrate with gauze, put the filtrate in refrigeration for 2 hours, filt...

Embodiment 2

[0054] Preparation of fruit wine: select the sea red fruit (calcium content 62.46mg / g) with full fruit, no rot, and no wormholes, clean it, remove impurities, remove stems, peel, and pit, put it in a container, and pour it into a solid-to-liquid ratio of 1: 10% liquid nitrogen, so that the sea red fruit is fully frozen for 5 minutes, and then fully crushed into powder with a pulverizer, and stored in a freezer. Take liquid nitrogen to treat the crushed sea red fruit, add water to dilute 30 times (solid-to-liquid ratio 1:30) to adjust the sugar content, add 1.0% pectinase, keep warm at 45°C for 5 hours, then filter and clarify. rejoin SO 2 , the concentration is 30mg / kg, put it into a 1.21MPa high-temperature sterilization pot for 20min for sterilization. Take it out, cool it to room temperature, inoculate it with activated high-efficiency Saccharomyces Angelica, and ferment it at 28°C for 2 days. Filtrate with gauze, put the filtrate in refrigeration for 2 hours, filter the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com