Method for detecting PVA coating on surface of composite reverse osmosis membrane

A reverse osmosis membrane and membrane surface technology, which is applied in the direction of measuring devices, analyzing materials through chemical reactions, and analyzing materials through observing the influence of chemical indicators, can solve the problem of time-consuming and inability to accurately judge surface coating. Substance and other problems, to achieve the effect of lower detection limit, stable color development, and PVA color sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

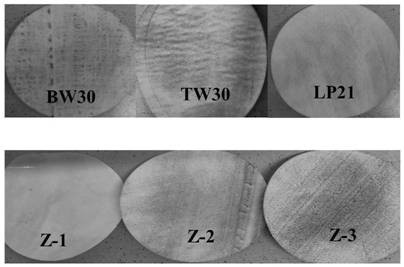

[0064] Test the distribution and amount of PVA coating on the surface of Dow Chemical Company No. BW30 diaphragm

[0065] Cut a 1m length from the BW30-400 membrane element broken membrane of Dow Chemical Company 8040 for use.

[0066] The specific test steps are as follows:

[0067] 1) Reverse osmosis membrane sampling: Use a disc sampler with a diameter of 7.8cm to randomly cut 5 discs from the membrane;

[0068] 2) Preparation of developer: prepare 10g / L octylphenyl polyoxyethylene ether solution, iodine-potassium iodide solution with iodine and potassium iodide concentrations of 12.7g / L and 25g / L respectively, and boric acid solution with a concentration of 40g / L , as a color developer, for use;

[0069] 3) Rapid color development judgment: Soak the disc in the mixed octylphenyl polyoxyethylene ether-iodine-boric acid color reagent solution with a volume ratio of 1:1:3 for 30 seconds, take it out and rinse it repeatedly with pure water until The washing solution is colo...

Embodiment 2

[0080] Test the distribution and amount of PVA coating on the surface of Dow Chemical Company No. TW30 diaphragm

[0081] Cut a 1m length from the broken diaphragm of TW30-1812-100 membrane element of Dow Chemical Company 1812 for use. The specific test steps are as follows:

[0082] 1) Reverse osmosis membrane sampling: randomly cut 15 discs from the membrane with a disc sampler with a diameter of 5.0 cm;

[0083] 2) Preparation of developer: prepare 5.0g / L nonylphenol polyoxyethylene ether solution, iodine-potassium iodide solution with iodine and potassium iodide concentrations of 10.0g / L and 20g / L respectively, and boric acid solution with a concentration of 30g / L , as a color developer, for use;

[0084] 3) Rapid color development judgment: Soak the disc in the mixed nonylphenol polyoxyethylene ether-iodine-boric acid color reagent solution with a volume ratio of 2:3:3 for 60 seconds, take it out and rinse it repeatedly with pure water until it is washed. The liquid is ...

Embodiment 3

[0095] The distribution and amount of PVA coating on the surface of Wharton Technology Co., Ltd. No. LP21 diaphragm during testing

[0096] Cut a 1m length from the LP21-4040 membrane element ruptured diaphragm of Times Wharton Technology Co., Ltd. 4040 for use. The specific test steps are as follows:

[0097] 1) Reverse osmosis membrane sampling: randomly cut 10 discs from the membrane with a disc sampler with a diameter of 10.0 cm;

[0098] 2) Chromogenic agent preparation: preparation of 20g / L polyoxyethylene lauryl ether solution, iodine, potassium iodide concentration is respectively the iodine-potassium iodide solution of 20.0g / L, 30g / L and the boric acid solution with concentration of 50g / L, as a developer Toner, for use;

[0099] 3) Rapid color development judgment: Soak the disc in the polyoxyethylene lauryl ether-iodine-boric acid color developer solution with a volume ratio of 1:0.1:1 for 120s, take it out and rinse it repeatedly with pure water until the washing l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com