System and method for preparing ammonia through urea hydrolysis based on peak regulation heat storage of coal-fired unit of thermal power plant

A coal-fired unit and urea hydrolysis technology, which is applied in the field of urea hydrolysis ammonia production system, can solve the problems of large volume of urea hydrolysis reactor, influence on power generation efficiency of unit, low utilization rate, etc., so as to improve flexibility and economy, reduce operation Cost, effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

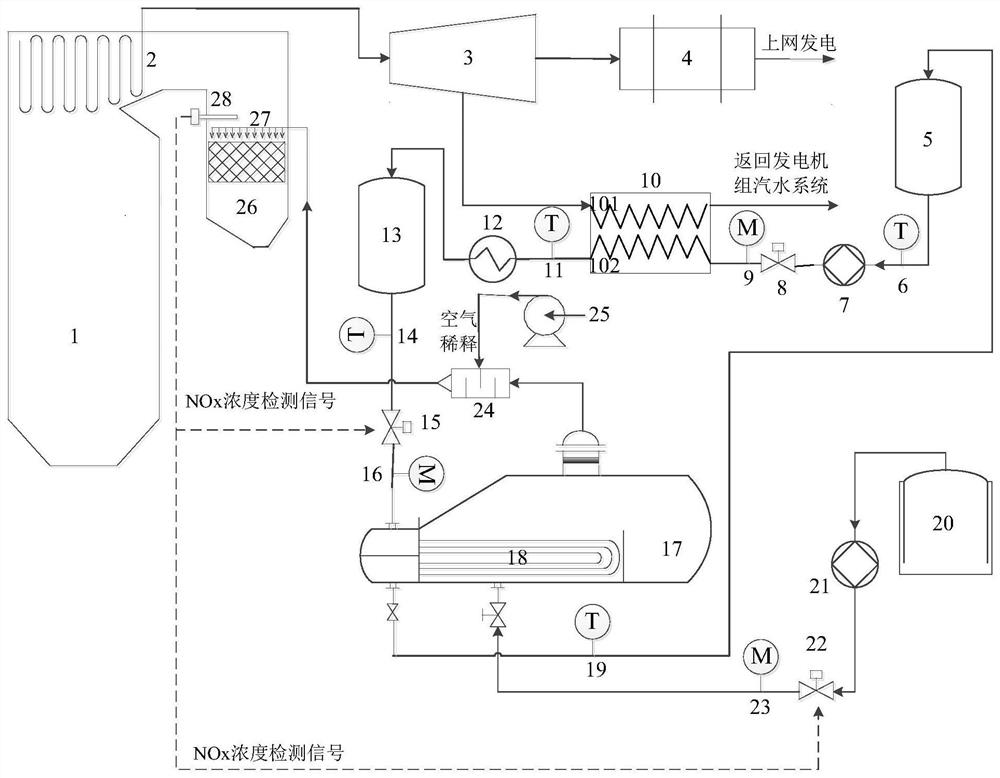

[0035] Urea hydrolysis ammonia production system based on peak regulation and heat storage of coal-fired units in thermal power plants, such as figure 1As shown, a gas unit consisting of a boiler 1, a steam turbine 3, and a generator 4, as well as a heat storage unit, a urea hydrolysis ammonia production unit, an SCR denitrification unit and a NOx concentration detection probe 28;

[0036] The heat storage unit includes a heat storage device 10, a heat transfer oil cold tank 5, a heat transfer oil hot tank 13, and an auxiliary electric heater 12; the heat storage device 10 is internally equipped with a heat storage medium, and through the heat storage medium is arranged Heat conduction heat storage circuit and heat release circuit; the heat storage circuit adopts the heat source pipeline 101 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com