Lithium cobalt oxide positive-electrode target material for preparing thin-film lithium battery and preparation method thereof

A technology of lithium cobalt oxide and lithium battery, applied in the field of lithium cobalt oxide cathode target and its preparation, can solve the problem of high contact surface resistance, achieve the effects of improving performance, perfect boosting and capacity expansion, and reducing contact surface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

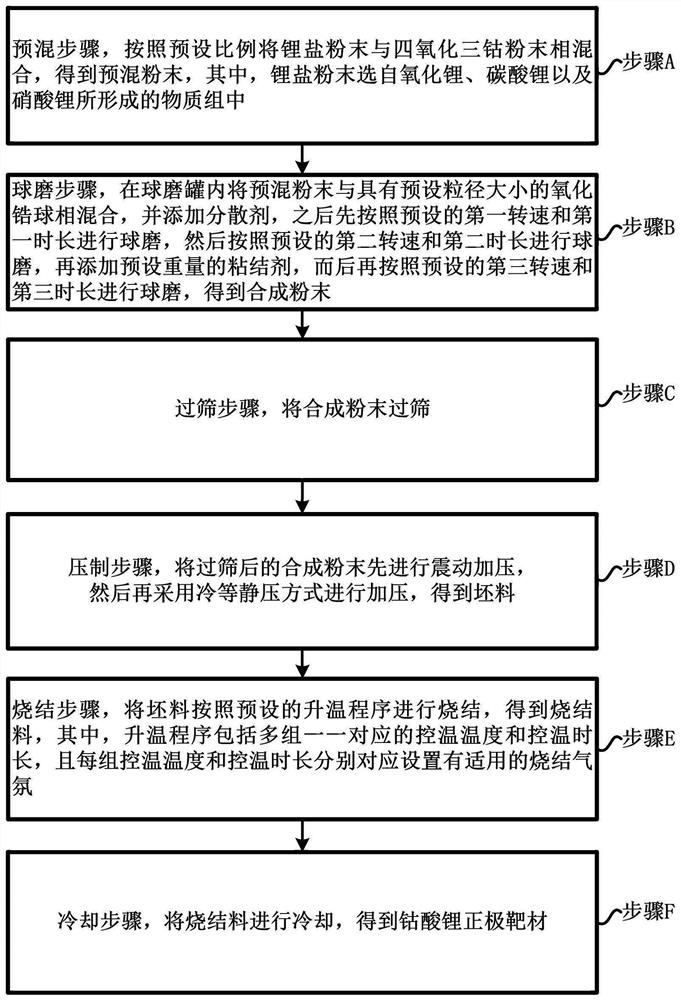

[0037] The preparation method of lithium cobaltate positive electrode target generally can comprise the following steps:

[0038] Step A: a premixing step, mixing lithium salt powder and cobalt tetroxide powder according to a preset ratio to obtain a premixed powder, wherein the lithium salt powder is selected from the group consisting of lithium oxide, lithium carbonate and lithium nitrate.

[0039] Step B: the ball milling step, in which the premixed powder is mixed with zirconia balls with a preset particle size in a ball mill tank, and a dispersant is added, and then ball milling is carried out according to the preset first rotation speed and first duration, and then Ball milling is carried out according to the preset second rotation speed and the second duration, and then a preset weight of binder is added, and then ball milling is performed according to the preset third rotation speed and the third duration to obtain a synthetic powder.

[0040] Step C: sieving step, sie...

Embodiment 1

[0072] Using the lithium cobalt oxide positive target material prepared by the above method, a single-section graphene-based thin-film lithium battery is deposited using magnetron sputtering coating technology: a graphene collector film with a thickness of 6 μm is coated on the surface of 1 square meter of copper foil, A negative electrode film, a solid electrolyte film, a positive electrode film and a graphene collector film are sequentially deposited on the graphene collector film. Among them, the thickness of the deposited negative electrode film is 4.5 μm, the thickness of the deposited solid electrolyte film is 1.5 μm, and the thickness of the deposited positive electrode film is 15 μm. A 6 μm graphene collector film is coated on the cathode film. The obtained battery has a capacity of 12240 (mA·h) after formation.

Embodiment 2

[0074] Using the lithium cobalt oxide positive target prepared by the above method, two graphene-based thin-film lithium batteries connected in series are deposited by magnetron sputtering coating technology: a graphene collector with a thickness of 7 μm is coated on the surface of 1 square meter copper foil film, and sequentially deposit negative electrode film, solid electrolyte film, positive electrode film, graphene collector film, negative electrode film, solid electrolyte film, positive electrode film and graphene collector film on the graphene collector film. Among them, the thickness of the negative electrode film of each deposited battery is 5.5 μm, the thickness of the solid electrolyte film of each battery is 2.0 μm, the thickness of the positive electrode film of each battery is 18.5 μm, and the thickness of the graphene collector film is 7 μm. The obtained battery has a capacity of 15096 (mA·h) after formation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com