Ice-cold feeling fabric containing zinc jade fibers and preparation method and application of ice-cold feeling fabric

A jade fiber and ice-cooling technology is applied to the field of cold-feeling fabric containing zinc jade fiber and its preparation field, which can solve the problems of reduced fiber breaking strength, influence on fiber properties, insufficient cooling feeling, etc. , the effect of improving the feeling of cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

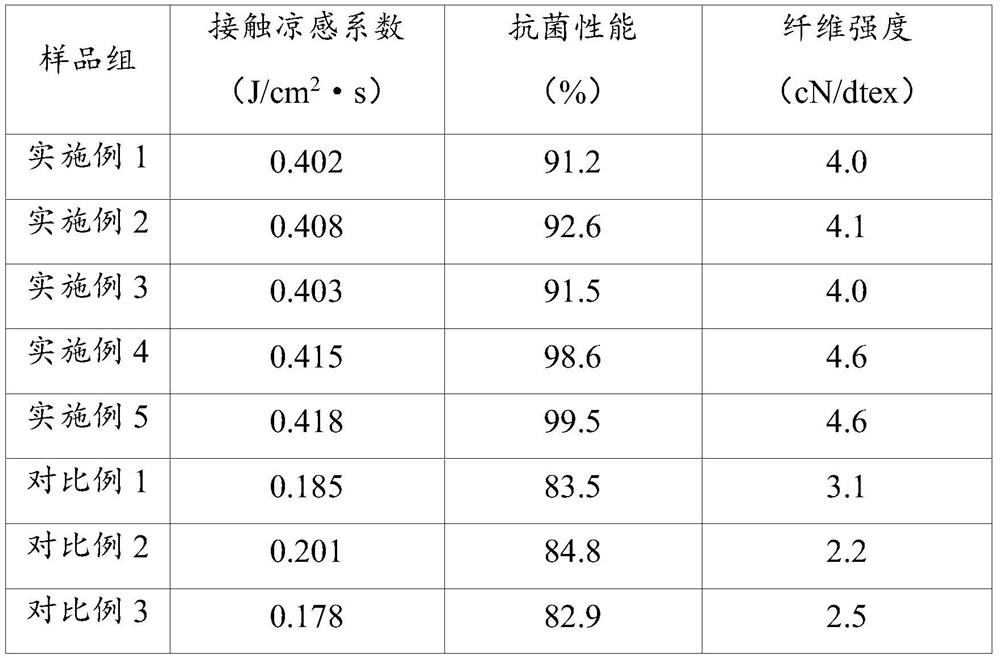

Examples

Embodiment 1

[0035] This example provides a cold feeling fabric containing zinc jade fiber, which is prepared by the following steps:

[0036] (1) Take the following materials in proportion: graphene: 25 parts, polystyrene: 30 parts, lignin: 16 parts, dimethyltetrahydrofuran: 180 parts, jade powder: 11 parts, nano-zinc oxide: 10 parts, Sodium tripolyphosphate: 4 parts;

[0037] (2) dissolving the graphene material, polystyrene and lignin in an organic solvent, extruding at a screw extrusion temperature of 180°C to obtain a mixed solution;

[0038] (3) Add jade powder and nano-zinc oxide into the mixed solution, stir at room temperature for 60 minutes, then add sodium tripolyphosphate and ultrasonically disperse for 30 minutes to obtain a mixed dispersion;

[0039] (4) blending and melting the mixed dispersion liquid and the spinning melt to obtain a spinning liquid, and the spinning liquid is electrospun at a temperature of 25° C. and a voltage of 11 kV to obtain zinc jade fibers;

[004...

Embodiment 2

[0043] This example provides a cold feeling fabric containing zinc jade fiber, which is prepared by the following steps:

[0044] (1) Weigh the following materials in proportion: graphene: 22 parts, polystyrene: 33 parts, lignin: 17 parts, N,N-dimethylformamide: 185 parts, jade powder: 12 parts, nano-oxidized Zinc: 10 parts, sodium tripolyphosphate: 4 parts;

[0045] (2) dissolving the graphene material, polystyrene and lignin in an organic solvent, extruding at a screw extrusion temperature of 190°C to obtain a mixed solution;

[0046] (3) Add jade powder and nano-zinc oxide into the mixed solution, stir at room temperature for 70 minutes, then add sodium tripolyphosphate and ultrasonically disperse for 40 minutes to obtain a mixed dispersion;

[0047] (4) blending and melting the mixed dispersion liquid and the spinning melt to obtain a spinning liquid, which is electrospun at a temperature of 36° C. and a voltage of 11 kV to obtain zinc jade fibers;

[0048] (5) blending ...

Embodiment 3

[0051] This example provides a cold feeling fabric containing zinc jade fiber, which is prepared by the following steps:

[0052] (1) Weigh the following materials in proportion: graphene: 25 parts, polystyrene: 30 parts, lignin: 16 parts, N,N-dimethylformamide: 185 parts, jade powder: 11 parts, nano-oxidation Zinc: 10 parts, stearic acid; 4 parts;

[0053] (2) dissolving the graphene material, polystyrene and lignin in an organic solvent, extruding at a screw extrusion temperature of 190°C to obtain a mixed solution;

[0054] (3) Add jade powder and nano-zinc oxide into the mixed solution, stir at room temperature for 80 minutes, then add stearic acid and ultrasonically disperse for 40 minutes to obtain a mixed dispersion;

[0055] (4) blending and melting the mixed dispersion liquid and the spinning melt to obtain a spinning liquid, and the spinning liquid is electrospun at a temperature of 25° C. and a voltage of 11 kV to obtain zinc jade fibers;

[0056] (5) blending zin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com