Novel environment-friendly cardboard material and preparation method thereof

An environmental protection and paper shell technology, applied in the separation of raw materials, paper, papermaking, etc., can solve the problems of poor strength of environmentally friendly paper, and achieve the effect of being suitable for large-scale production, high economic benefits, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

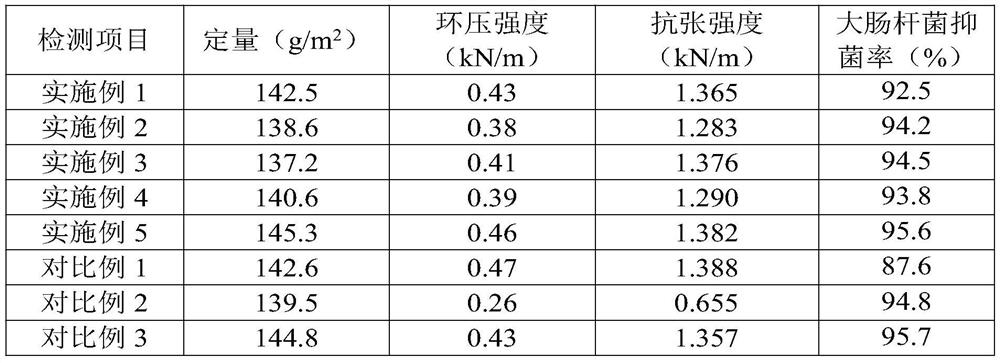

Examples

Embodiment 1

[0029] A new type of environmentally friendly paper shell material and its preparation method

[0030] The preparation method of novel environment-friendly paper shell material comprises the following steps:

[0031] Step S10, adding fly ash fibers into water, ultrasonically dispersing for 3 minutes and raising the temperature to 80°C, adding a softener, after 10 minutes of treatment, suction filtration, drying, and grinding to obtain pretreated fly ash; the softening The agent is acetic acid;

[0032] Step S20, clean the corn cob and bagasse separately, the weight ratio of corn cob and bagasse is 10:5, put them in an oven for drying, pulverize them with a pulverizer, and then grind them to obtain a mixture with a particle size of less than 40 mesh. powder;

[0033] Step S30, mix 30 parts of recycled pulp and 15 parts of plant fiber pulp in a beater, and then add 15 parts of the mixed powder obtained in step S20, 5 parts of pretreated fly ash obtained in step S10, and 8 part...

Embodiment 2

[0039] A new type of environmentally friendly paper shell material and its preparation method

[0040] The preparation method of novel environment-friendly paper shell material comprises the following steps:

[0041] Step S10, adding fly ash fibers into water, ultrasonically dispersing for 3 minutes and raising the temperature to 85°C, adding a softener, after 45 minutes of treatment, suction filtration, drying, and grinding to obtain pretreated fly ash; the softening The agent is hydrochloric acid;

[0042] Step S20, clean the corn cob and bagasse respectively, the weight ratio of corn cob and bagasse is 10:8, put them in an oven for drying, pulverize them with a pulverizer and then grind them to obtain a mixture with a particle size of less than 40 mesh. powder;

[0043] Step S30, mixing 55 parts of recycled pulp and 40 parts of plant fiber pulp in a beater, and then adding 35 parts of the mixed powder obtained in step S20, 15 parts of pretreated fly ash obtained in step S...

Embodiment 3

[0049] A new type of environmentally friendly paper shell material and its preparation method

[0050] The preparation method of novel environment-friendly paper shell material comprises the following steps:

[0051] Step S10, adding fly ash fibers into water, ultrasonically dispersing for 3 minutes and raising the temperature to 82°C, adding a softener, after 15 minutes of treatment, suction filtration, drying, and grinding to obtain pretreated fly ash; the softening The agent is a silane coupling agent;

[0052] Step S20, clean the corn cob and bagasse respectively, the weight ratio of corn cob and bagasse is 10:6, put them in an oven for drying, pulverize them with a pulverizer, and then grind them to obtain a mixture with a particle size of less than 40 mesh. powder;

[0053] Step S30, mix 35 parts of recycled pulp and 20 parts of plant fiber pulp in a beater, and then add 20 parts of the mixed powder obtained in step S20, 7 parts of pretreated fly ash obtained in step S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com