Hierarchical structure hybrid loaded atomic precision gold nanocluster catalyst and preparation method thereof

A technology of gold nanoclusters and hybrids, applied in the field of noble metal nanocatalysts, to achieve large specific surface area, obvious performance advantages, and the effect of improving specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

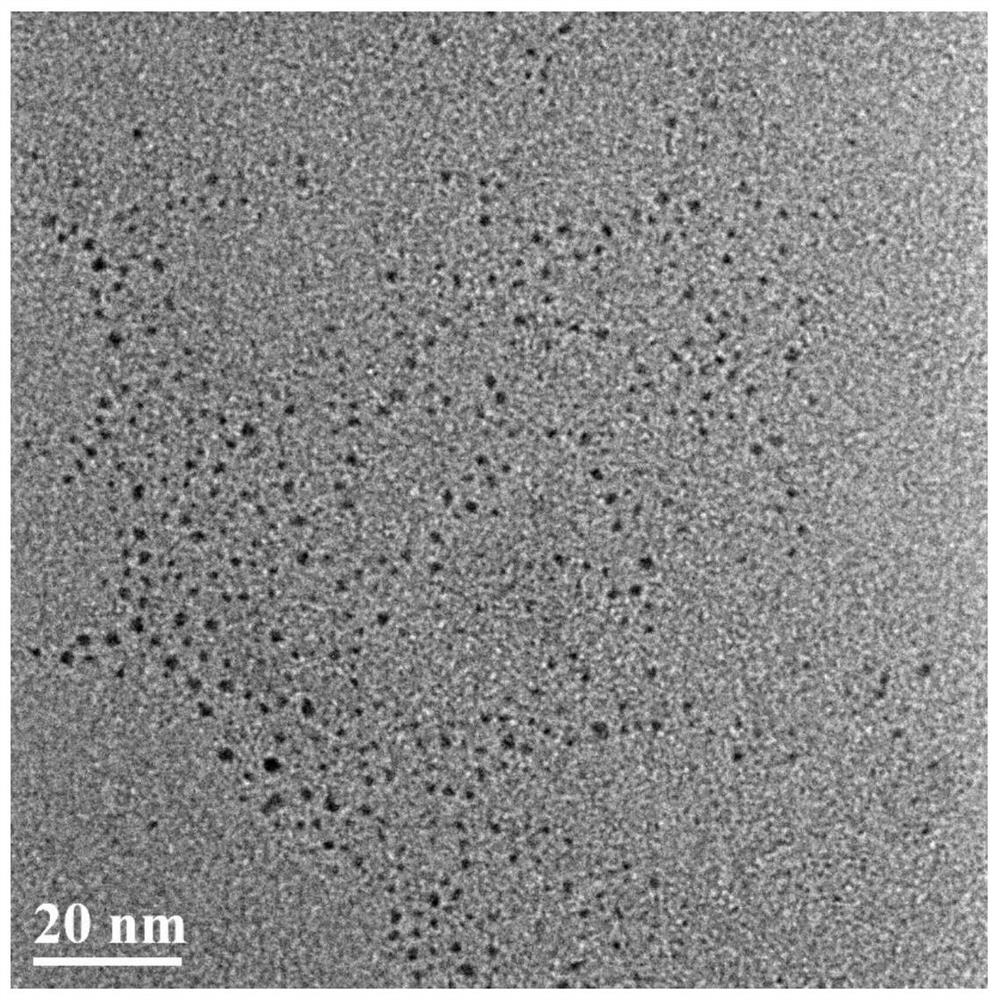

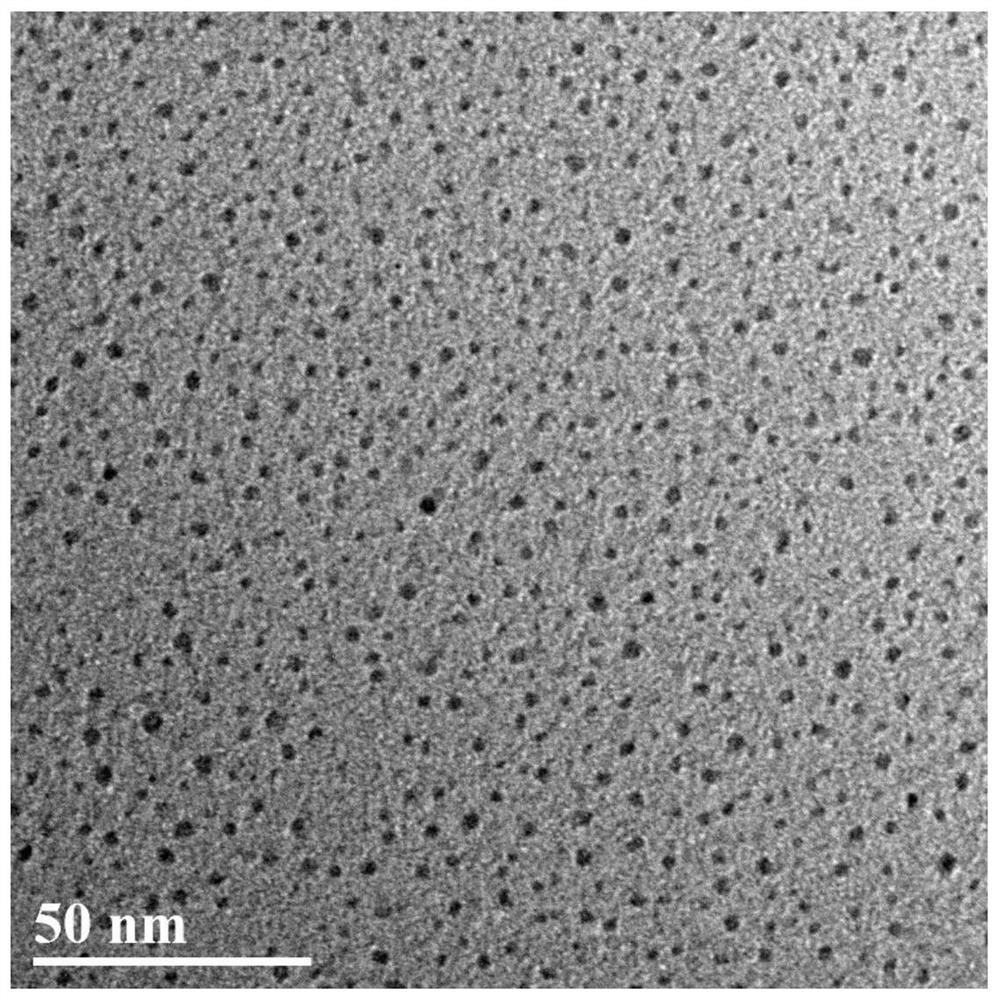

[0027] (1) Au 25 Capt 18 Preparation of nanoclusters

[0028] Weigh 1.0g of HAuCl 4 4H 2 O into 100mL methanol, configure to obtain 10mg / mL chloroauric acid methanol solution, measure 24.69mL of the above solution and 0.3804g TOABr (0.69mmol) into a 100mL single-necked flask filled with 20.31mL methanol, at 25±1°C in a water bath at 1200rpm With magnetic stirring, the mixture turned from orange yellow to deep red. After 15 minutes, 0.3912g captopril (0.60mmol) was added in the reaction solution, and the color of the solution turned white rapidly. After reacting for 30 minutes, the stirring rate was adjusted to 600rpm, and then 15mL NaBH 4 The ice solution was quickly added to the above reaction solution, and the color of the solution immediately changed to brown-green. After the above reaction solution was continuously reacted in a water bath at 25°C for 48 hours, it was centrifuged (4800r / min, 20min) to remove unreacted and insoluble Au(I):Capt polymer. The supernatant...

Embodiment 2

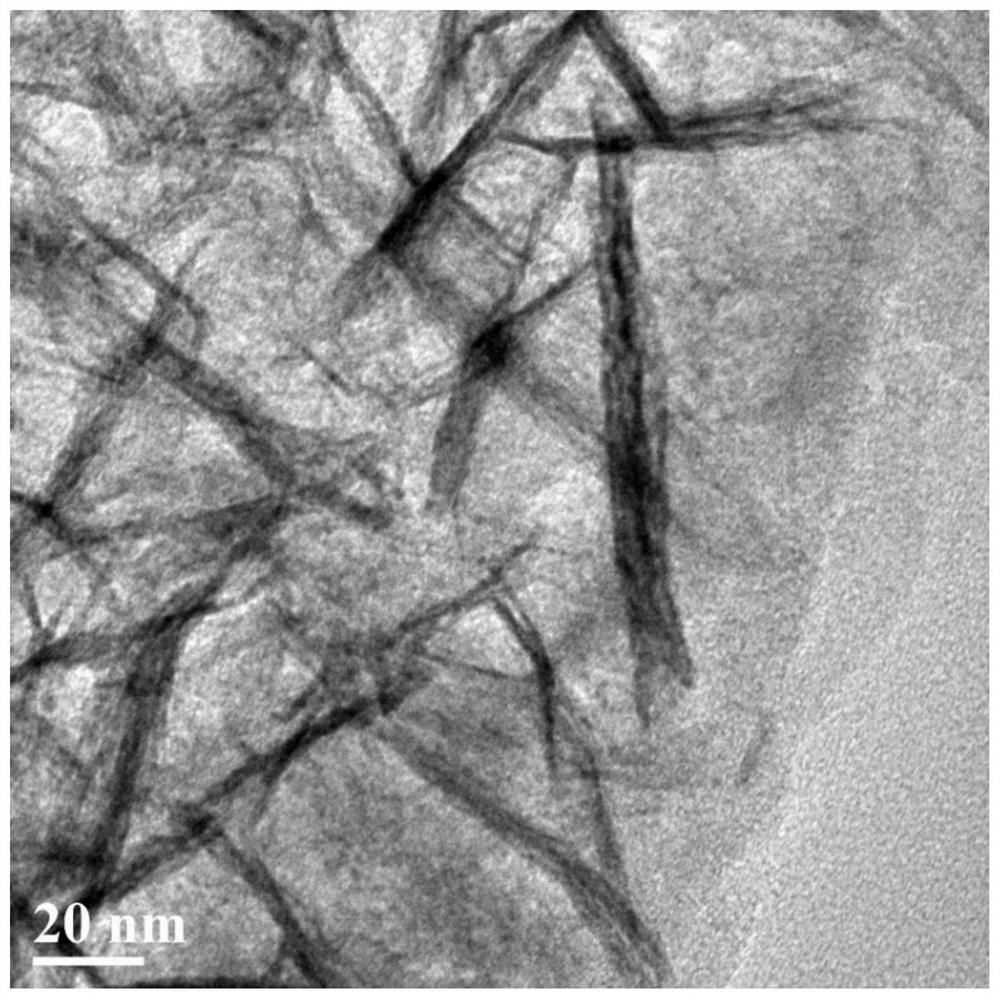

[0035] (1) Au 25 Capt 18 The preparation of nanoclusters is the same as in Example 1.

[0036] (2)Ni 3 The preparation of the Al-LDH / rGO hybrid carrier is the same as in Example 1.

[0037] (3) Au 25 / Ni 3 Preparation of Al-LDH / rGO catalyst

[0038] 25mg Au 25 Capt 18 Nanoclusters were dissolved in 100mL deionized water to obtain 0.25mg / mL Au 25 Capt 18 aqueous solution. 1.0g of Ni 3 The Al-LDH / rGO hybrid carrier was placed in a 150 mL beaker, 50 mL of deionized water and an appropriate amount of 0.1 mol / L sodium carbonate solution were added and ultrasonicated for 15 minutes to obtain a hybrid carrier dispersion with pH ~ 10.0. Measure 20mL0.25mg / mL Au 25 Capt 18 Aqueous solution, add an appropriate amount of 0.1mol / L sodium carbonate solution to adjust the pH to 8.0 in advance, add it to the above carrier dispersion under vigorous stirring, the theoretical loading of gold nanoclusters is 0.5wt%, and stir at 1000rpm for 4 hours. The mixture was collected by cent...

Embodiment 3

[0040] (1) Au 25 Capt 18 The preparation of nanoclusters is the same as in Example 1.

[0041] (2)Ni 3 The preparation of the Al-LDH / rGO hybrid carrier is the same as in Example 1.

[0042] (3) Au 25 / Ni 3 Preparation of Al-LDH / rGO catalyst

[0043] 25mg Au 25 Capt 18 Nanoclusters were dissolved in 100mL deionized water to obtain 0.25mg / mL Au 25 Capt 18 aqueous solution. 1.0g of Ni 3 The Al-LDH / rGO hybrid carrier was placed in a 150 mL beaker, 50 mL of deionized water and an appropriate amount of 0.1 mol / L sodium carbonate solution were added and ultrasonicated for 10 minutes to obtain a hybrid carrier dispersion with pH ~ 8.0. Measure 20mL0.25mg / mL Au 25 Capt 18 Aqueous solution, add an appropriate amount of 0.1mol / L sodium carbonate solution to adjust the pH to 8.0 in advance, add it to the above carrier dispersion under vigorous stirring, the theoretical loading of gold nanoclusters is 0.5wt%, and stir at 1000rpm for 4 hours. The mixture was collected by centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com