Low-frequency radar wave absorbent and preparation method thereof

A low-frequency radar and wave absorption technology, used in antennas, electrical components, magnetic field/electric field shielding and other directions, can solve the problems of loss of magnetic loss performance, high distance resolution, affecting wave absorption performance, etc., to improve wave absorption performance, preparation Simple process and excellent electromagnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

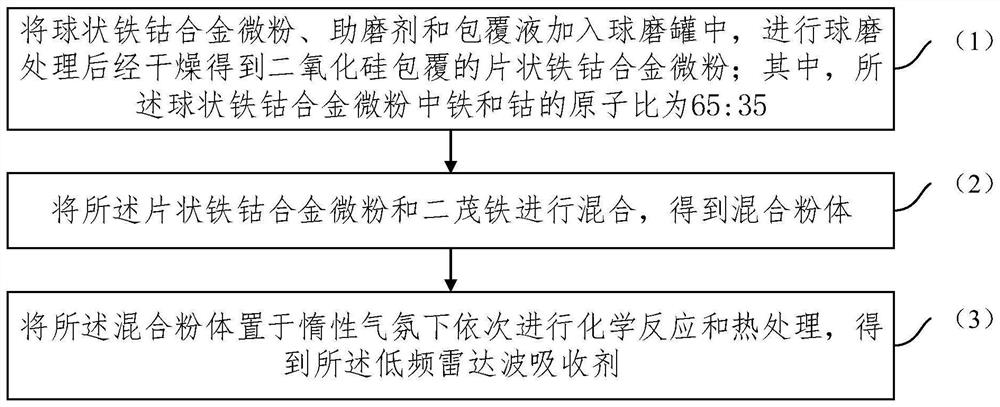

[0036] Such as figure 1 As shown, the invention provides a kind of preparation method of low-frequency radar wave absorber, and this preparation method comprises the steps:

[0037] (1) adding spherical iron-cobalt alloy micropowder, grinding aid and coating solution into a ball milling tank, and drying to obtain flaky iron-cobalt alloy micropowder coated with silicon dioxide after ball milling; wherein, the spherical iron-cobalt alloy The atomic ratio of iron and cobalt in the micropowder is 65:35;

[0038] (2) mixing the flaky iron-cobalt alloy micropowder and ferrocene to obtain a mixed powder;

[0039] (3) placing the mixed powder in an inert atmosphere to carry out chemical reaction and heat treatment in sequence to obtain the low-frequency radar wave absorber.

[0040] It should be noted that the spherical iron-cobalt alloy fine powder is the spherical Fe65Co35 alloy fine powder.

[0041] In the present invention, flake iron-cobalt alloy micropowder is used as a magne...

Embodiment 1

[0077] (1) Add spherical iron-cobalt alloy fine powder, grinding aid (calcium stearate) and coating liquid (tetraethyl silicate) with a mass ratio of 2000:2:9 into the ball mill jar, and grind at a speed of 800r After ball milling for 9 hours under the condition of / min, the solid product was obtained by drying, and the solid product was screened with a standard sieve of 44 μm (i.e. 325 mesh) to obtain flaky iron-cobalt alloy micropowder coated with silica (particle size≤ 44 μm); wherein, the atomic ratio of iron and cobalt in the spherical iron-cobalt alloy powder is 65:35;

[0078] Wherein, the ball milling medium in the ball milling process is absolute ethanol, the ball-to-material ratio is 4:1, and a diameter of 5 mm is selected for use as zirconia balls;

[0079] (2) Place the flaky iron-cobalt alloy micropowder and ferrocene obtained in step (1) in a V-type mixer, and mix for 2h under the condition that the feeding speed is 10r / min, to obtain a mixed powder; wherein, Th...

Embodiment 2

[0083] (1) Add spherical iron-cobalt alloy fine powder, grinding aid (calcium stearate) and coating solution (tetraethyl silicate) with a mass ratio of 1500:3:8 into the ball mill jar, and grind at a speed of 700r After ball milling under the condition of 7h / min, the solid product was obtained by drying, and the solid product was screened with a standard sieve of 44 μm (i.e. 325 mesh) to obtain flaky iron-cobalt alloy micropowder coated with silica (particle size≤ 44 μm); wherein, the atomic ratio of iron and cobalt in the spherical iron-cobalt alloy powder is 65:35;

[0084] Wherein, the ball milling medium in the ball milling process is absolute ethanol, the ball-to-material ratio is 4:1, and a diameter of 4 mm is selected for use as zirconia balls;

[0085] (2) Place the flaky iron-cobalt alloy micropowder and ferrocene obtained in step (1) in a V-type mixer, and mix for 2 hours under the condition that the feeding speed is 15r / min, to obtain a mixed powder; wherein, The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com