Phosphorus-doped platinum-nickel nanowire and preparation method and application thereof

A nanowire and phosphorus-doped technology, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high price of platinum-carbon catalysts and the need to improve catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

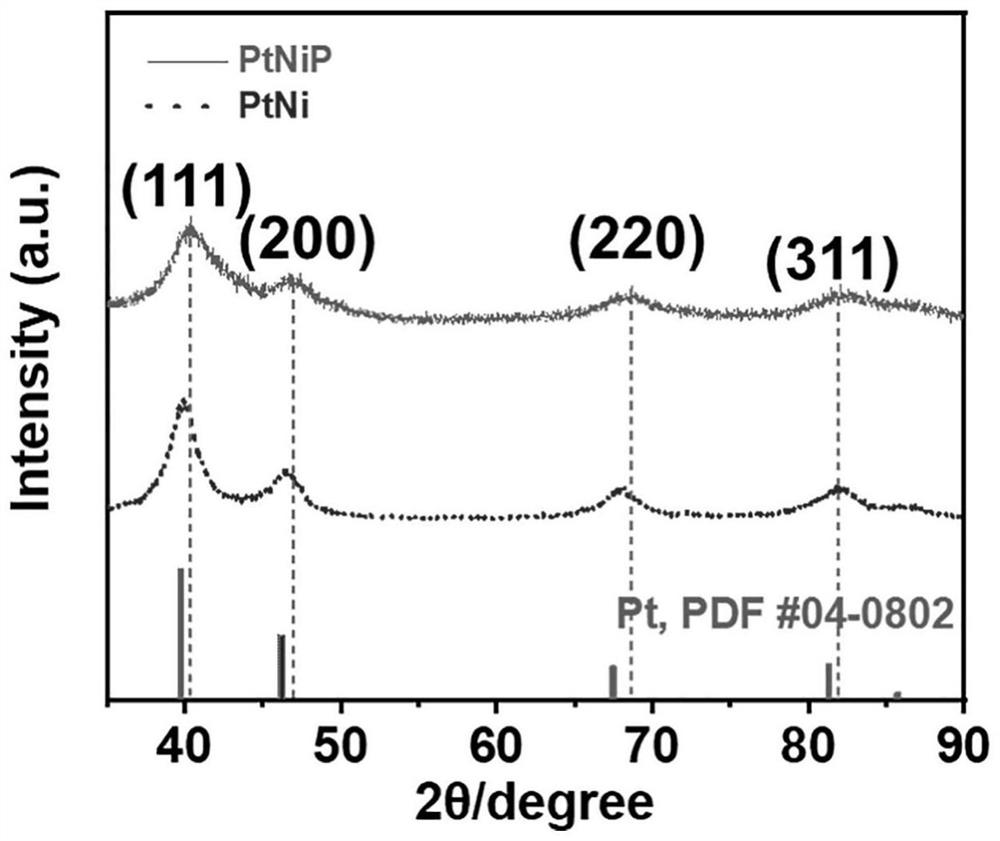

[0028] The invention provides a method for preparing phosphorus-doped platinum-nickel nanowires, comprising the following steps:

[0029] (1) mixing a platinum source, a nickel salt, an alkali metal hydroxide, ethylene glycol and N,N-dimethylformamide, and subjecting the resulting mixed solution to a first hydrothermal reaction to obtain platinum-nickel nanowires;

[0030] (2) Mixing the platinum-nickel nanowires, phosphorus source and ethylene glycol, and subjecting the obtained mixture to a second hydrothermal reaction to obtain phosphorus-doped platinum-nickel nanowires.

[0031] In the present invention, unless otherwise specified, the raw materials used are commercially available products well known in the art.

[0032] The invention mixes platinum source, nickel salt, alkali metal hydroxide, ethylene glycol and N,N-dimethylformamide, and performs the first hydrothermal reaction on the obtained mixed solution to obtain platinum-nickel nanowires.

[0033] In the present i...

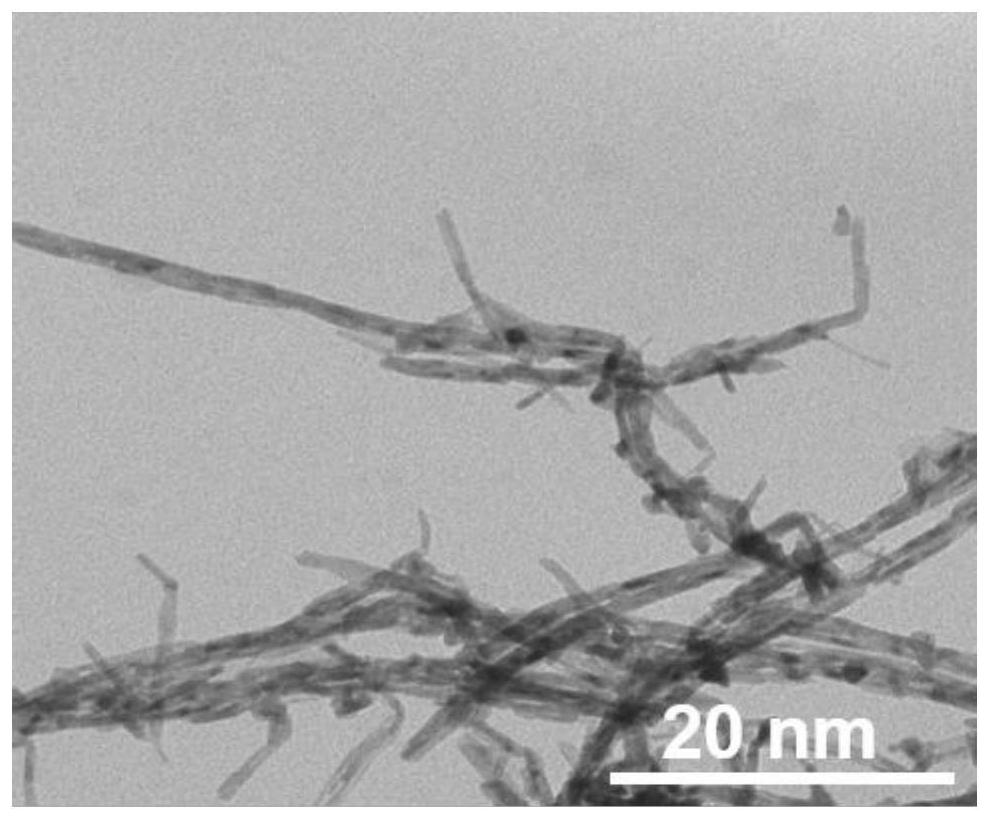

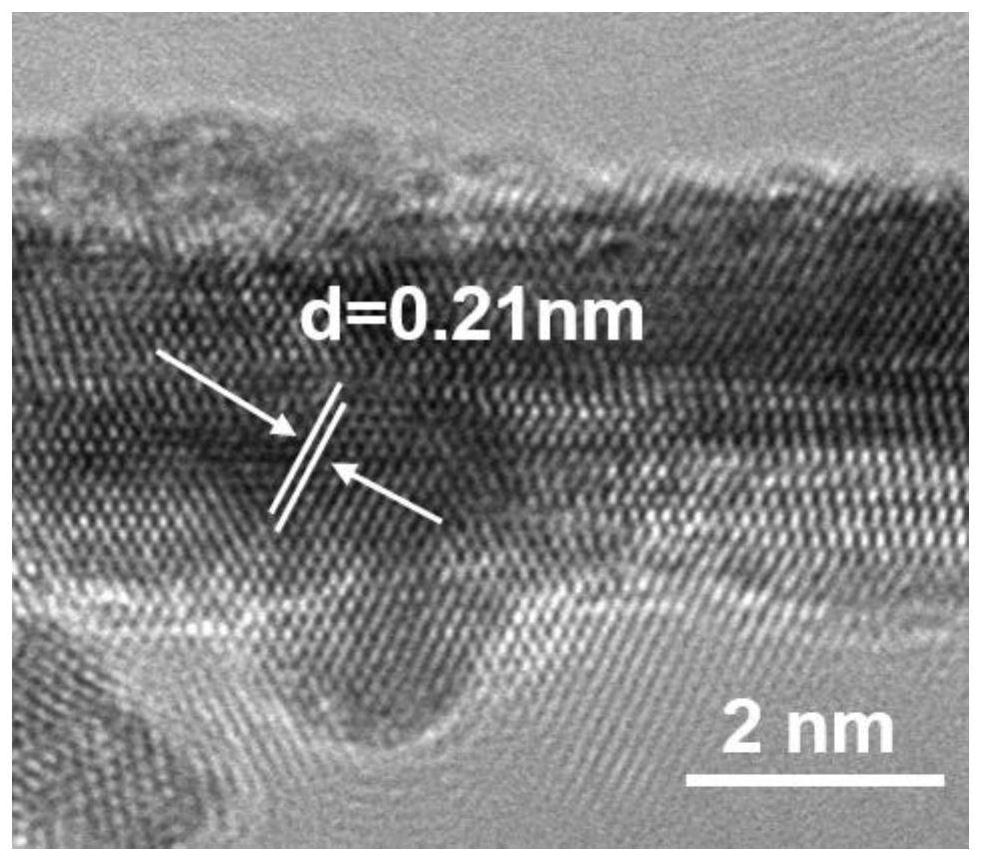

Embodiment 1

[0048] Ammonium chloroplatinate ((NH 4 ) 2 PtCl 6 ,70mg), potassium hydroxide (KOH,500mg) and nickel chloride hexahydrate (NiCl 2 ·6H 2 O, 20 mg) was added to a mixed solution composed of ethylene glycol (EG, 9 mL) and N,N-dimethylformamide (DMF, 3 mL), and after stirring at 50°C for 3 h, the synthesized homogeneous yellow solution was transferred to polytetrafluoroethylene In a vinyl fluoride-lined stainless steel autoclave, conduct a hydrothermal reaction at 170°C for 8 hours. After cooling to room temperature, the product is collected by filtration, washed three times with a mixture of ethanol / deionized water, and dried at room temperature to obtain platinum-nickel nanowires.

[0049] Dissolve 30mg of platinum-nickel nanowires and 3mg of phosphorous powder in 13mL of ethylene glycol, and after stirring, a uniform red solution is synthesized and transferred to a polytetrafluoroethylene-lined stainless steel autoclave, subjected to hydrothermal reaction at 180°C for 8 hour...

Embodiment 2

[0051] Ammonium chloroplatinate ((NH 4 ) 2 PtCl 6 ,70mg), potassium hydroxide (KOH,500mg) and nickel chloride hexahydrate (NiCl 2 ·6H 2 O, 10mg) was added to a mixed solution composed of ethylene glycol (EG, 9mL) and N,N-dimethylformamide (DMF, 3mL), and after stirring at 50°C for 3h, the synthesized homogeneous yellow solution was transferred to polytetrafluoroethylene In a vinyl fluoride-lined stainless steel autoclave, conduct a hydrothermal reaction at 170°C for 8 hours. After cooling to room temperature, the product is collected by filtration, washed three times with a mixture of ethanol / deionized water, and dried at room temperature to obtain platinum-nickel nanowires.

[0052] Dissolve 30mg of platinum-nickel nanowires and 3mg of phosphorus powder in 13mL of ethylene glycol, stir to form a uniform red solution, transfer it to a polytetrafluoroethylene-lined stainless steel autoclave, heat at 180°C for 8 hours, cool to room temperature, and filter The product was col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com