Welding seam forming regulation and control method based on space arc-shaped track arc swing coupling welding parameter follow-up

A welding parameter, arc-shaped technology, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the problems of poor universality, strict process conditions and equipment requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

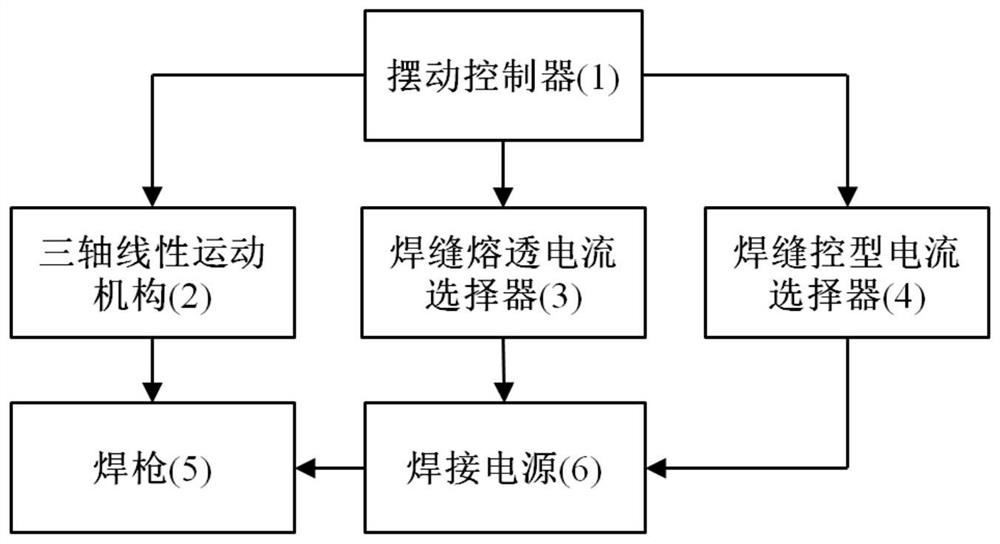

[0025] Embodiment 1: The system block diagram of a welding seam forming control method based on the arc swing coupled welding parameters of the present invention is as follows figure 1 As shown, it includes a swing controller (1), a three-axis linear motion mechanism (2), a weld penetration current selector (3), a weld seam control current selector (4), a welding torch (5), a welding power supply ( 6); the swing controller (1) drives the three-axis linear motion mechanism (2) to drive the welding torch (5) to carry out swing welding with a space arc-shaped trajectory, and the three-axis motion equation of the space arc-shaped trajectory arc swing is:

[0026]

[0027]

[0028]

[0029] The above motion equations all take the weld center of the current swing period as the reference coordinate system, where T is the swing period, ω s is the arc motion angular velocity, B is the swing width, L is the swing step, R x is the radius of curvature in the x-axis direction, R ...

Embodiment 2

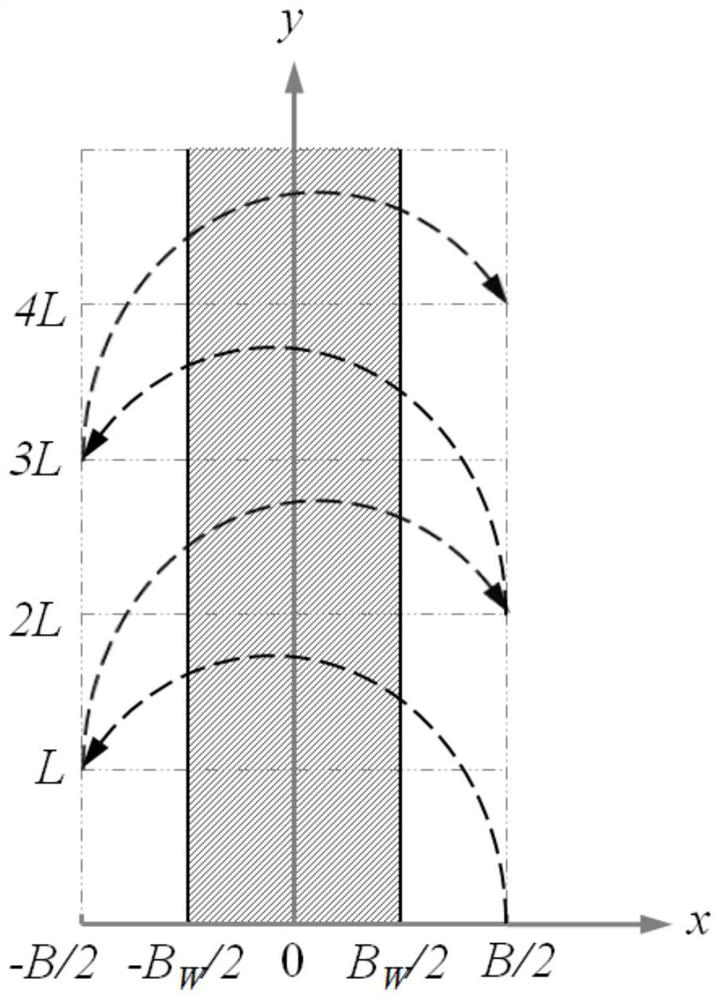

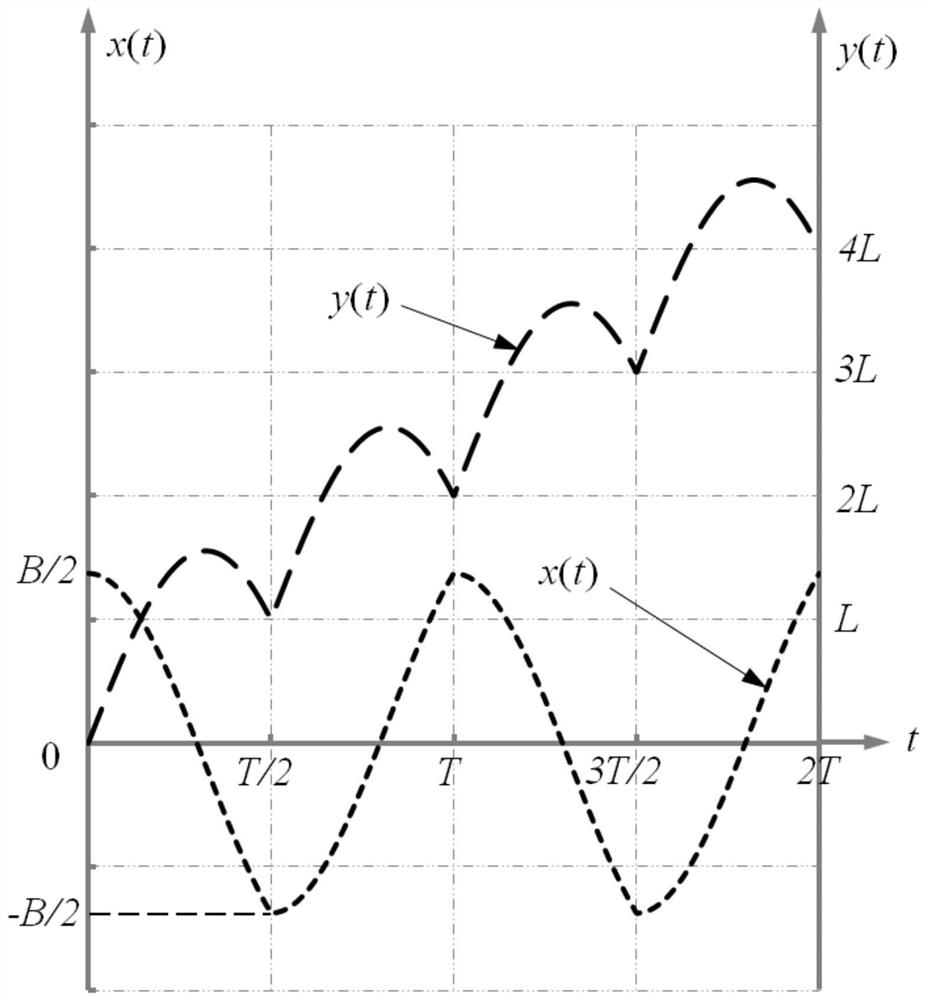

[0031] Embodiment 2: The swing controller (1) drives the three-axis linear motion mechanism (2) to drive the welding torch (5) to perform swing welding with a space arc-shaped trajectory, and the space arc-shaped trajectory and its arc swing process are in the x-y plane projection as figure 2 As shown, the starting point of arc motion is still at (B / 2,0,f H B / 2) as an example, the schematic diagram of the motion trajectory x(t) and y(t) in the x-axis direction and y-axis direction of the arc swing is as follows image 3 As shown, its arc motion process is the same as that of Embodiment 1, and will not be repeated.

Embodiment 3

[0032] Embodiment 3: The swing controller (1) drives the three-axis linear motion mechanism (2) to drive the welding torch (5) to perform swing welding with a space arc-shaped trajectory, and the projection of the space arc-shaped trajectory on the x-y plane is as follows figure 2 As shown, the schematic diagram of the motion trajectory x(t) and y(t) in the x-axis direction and y-axis direction of the arc swing is as follows image 3 As shown, the curvature adjustment coefficient f in the Z-axis direction H = 0.3 as an example, the Z-axis motion trajectory z(t) of the arc swing and the schematic diagram of its relationship with x(t) are as follows Figure 4 As shown, its arc motion process is the same as that of Embodiments 1 and 2, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com