Self-compacting concrete prepared from modified ceramic polishing powder and preparation method of self-compacting concrete

A technology of self-compacting concrete and ceramic polishing powder, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc. problems, to achieve the effect of convenient construction control, reduction of losses, and improvement of water retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing self-compacting concrete prepared by using modified ceramic polishing powder, which comprises the following preparation steps:

[0034] (1) Weighing each raw material: Weighing cement, modified ceramic polishing powder, fly ash, coarse aggregate, artificial sand, water and polycarboxylate high-performance water reducer by certain parts by weight;

[0035] (2) Mix the coarse aggregate and artificial sand and stir evenly to form mixture A; mix cement, modified ceramic polishing powder and fly ash and stir evenly to form mixture B; mix polycarboxylate high-performance water reducer and After the water is mixed, stir evenly to obtain a mixed solution C;

[0036](3) Pour mixture A and mixture B into a mixer and stir for 20-30 seconds, then add mixed liquid C and stir for 180-240 seconds to obtain self-compacting concrete prepared using modified ceramic polishing powder.

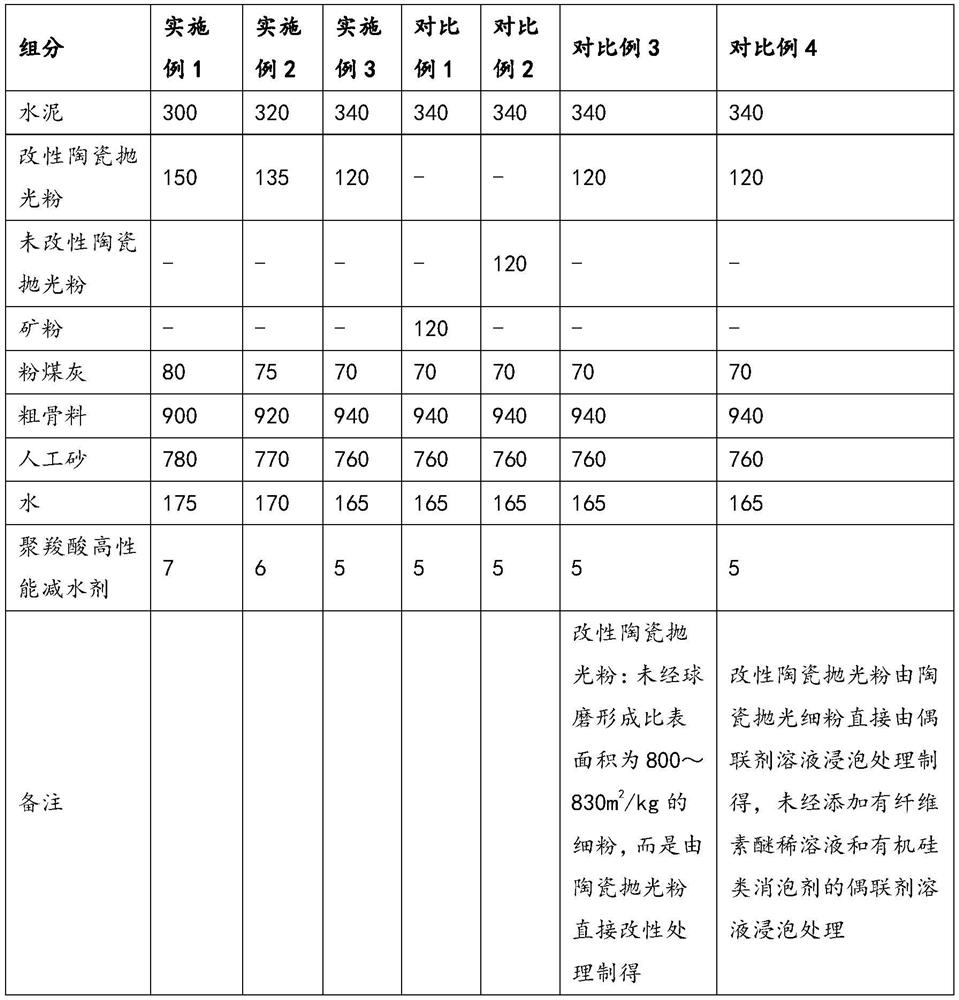

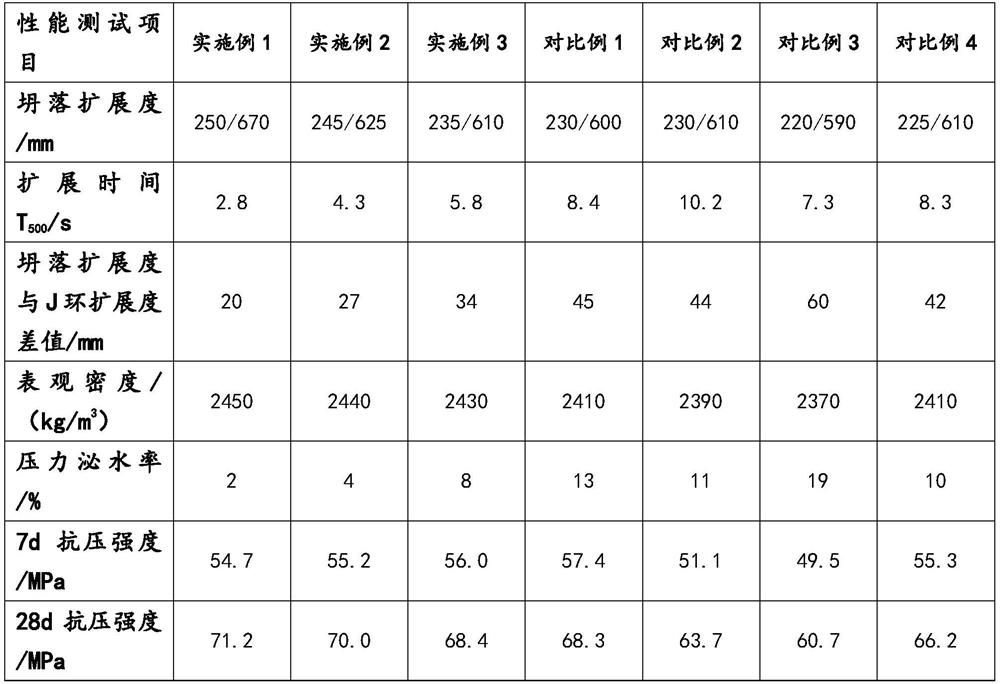

[0037] Among them, the formula of the self-compacting con...

Embodiment 1

[0047] In this embodiment, in parts by weight, each raw material composition includes: 300 parts of cement, 150 parts of modified ceramic polishing powder, 80 parts of fly ash, 900 parts of coarse aggregate, 780 parts of artificial sand, 175 parts of tap water, polycarboxylate 7 parts of acid high-performance water reducer;

[0048] The specific preparation process of modified ceramic polishing powder is:

[0049] The ceramic polishing powder is ball-milled into a specific surface area of 830m through an all-round planetary ball mill 2 / kg ceramic polishing fine powder; transfer the ceramic polishing fine powder to an ultrasonic cleaning machine, ultrasonically clean and dry for 1.5 hours; soak the ceramic polishing fine powder after cleaning and drying in 9600g of coupling agent dilute solution After 0.5h, 10g of cellulose ether dilute solution and 2g of silicone defoamer were added dropwise, stirred for another 1h, filtered and dried to obtain modified ceramic polishing p...

Embodiment 2

[0058] In this embodiment, in terms of parts by weight, the composition of each raw material includes: 320 parts of cement, 135 parts of ceramic polishing powder, 75 parts of fly ash, 920 parts of coarse aggregate, 770 parts of artificial sand, 170 parts of tap water, high polycarboxylate 6 parts of performance water reducing agent;

[0059] Among them, the specific preparation process of the modified ceramic polishing powder is as follows: the ceramic polishing powder is ball-milled into a specific surface area of 800m 2 / kg of fine ceramic polishing powder; transfer the fine ceramic polishing powder to an ultrasonic cleaning machine, ultrasonically clean and dry for 1.5 hours; soak the fine ceramic polishing powder after cleaning and drying in a dilute coupling agent solution for 0.5 h, drop in dilute cellulose ether solution and silicone defoamer, stir for another 1 h, filter and dry to obtain modified ceramic polishing powder, store it for future use.

[0060] Among the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com