Method for producing whole wheat sour dough leavening agent by utilizing strain synergistic enzyme treatment technology

A technology for sourdough and enzyme treatment, which is applied in the field of leavening agents, can solve the problem that the improvement effect of sourdough starter whole wheat flour fermentation products is not obvious, the palatability, texture characteristics and popularization of whole wheat products are affected, and the degradation effect of insoluble cellulose is affected. Insignificant and other problems, to achieve the effect of facilitating quality control, improving nutritional properties and antioxidant properties, and improving palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

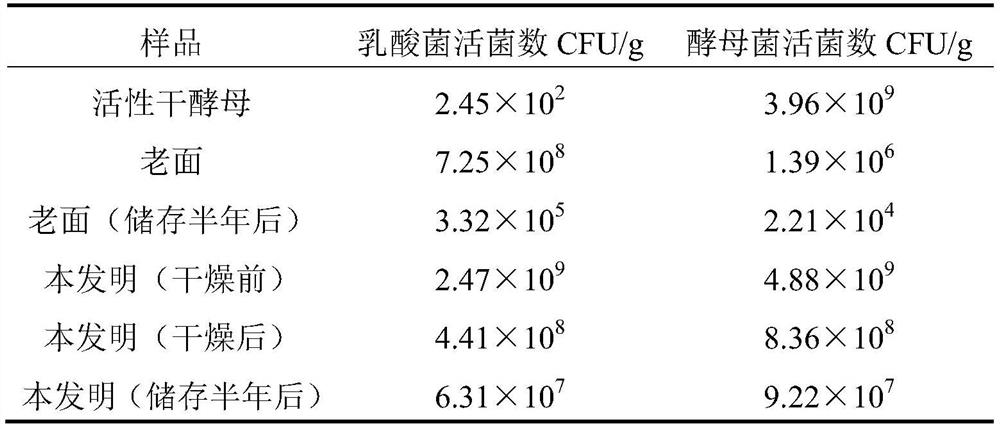

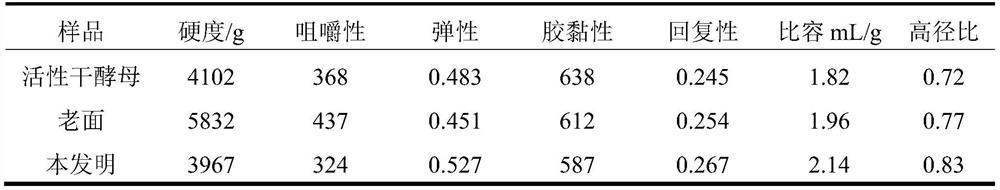

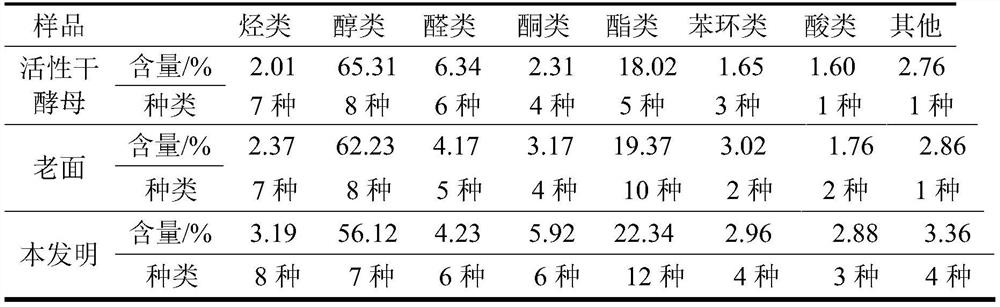

[0037] Production of whole-wheat sourdough starter with cellulase xylanase by strains and comparative analysis of its quality.

[0038] Lactobacillus brevis and Saccharomyces cerevisiae were cultured after the primary activation, and then the lactic acid bacteria were re-inoculated and cultivated according to the inoculation amount of 2% (v / v) and yeast according to 5% (v / v) to obtain a bacterial suspension. The two bacterial suspensions were centrifuged at a speed of 5000r / min for 10min, the culture solution in the upper layer was discarded, and the sludge sediment in the lower layer was washed with 20mL of 0.85% normal saline and centrifuged twice to obtain the sludge sediment. Whole wheat flour 100g, water 65g, cellulase and pentosanase additions were 40mg / g and 60mg / g, and the initial inoculum of lactic acid bacteria was 10 9 CFU / g whole wheat flour, the initial inoculum of yeast was 1010 CFU / g whole wheat flour, mixed well, and fermented at 37°C and 85% humidity for 12 ho...

Embodiment 2

[0048] Lactobacillus plantarum and saccharomyces were cultured after the primary activation, and then the lactic acid bacteria were re-inoculated and cultured at an inoculum size of 2% (v / v) and saccharomyces at 5% (v / v) to obtain a bacterial suspension. The bacterial suspension was centrifuged at a speed of 5000r / min for 10min, the upper culture solution was discarded, and the lower bacterial sludge was washed with 20mL of 0.85% normal saline and centrifuged twice to obtain the bacterial sludge. Whole wheat flour 100g, water 65g, cellulase and pentosanase additions were 40mg / g and 60mg / g, and the initial inoculum of lactic acid bacteria was 10 8 CFU / g whole wheat flour, the initial inoculum of yeast was 10 10 CFU / g whole wheat flour, mixed well, and fermented at 37°C and 85% humidity for 12 hours; adding 400% sterile saline, followed by low-temperature spray drying to obtain a whole wheat sourdough starter. The spray drying conditions are inlet temperature 130°C; outlet temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com