Aluminum template surface cleaning agent

A surface cleaning agent and aluminum template technology, which is applied in the field of metal material cleaning, can solve the problems of serious corrosion loss of the aluminum template substrate, affecting normal use, rust spots on the surface of the aluminum template, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An aluminum template surface cleaning agent, comprising the following raw materials in parts by weight: 6 parts of corrosion inhibitor, 3 parts of sodium gluconate, 5 parts of acetic acid, 2 parts of sodium silicate, 2 parts of fatty acid methyl ester ethoxylate sulfonate, 40 parts of ionized water;

[0032] The aluminum template surface cleaning agent is made by the following steps:

[0033] The above raw materials were weighed, mixed, and stirred for 1 hour under the condition of a rotating speed of 1500 r / min to prepare an aluminum template surface cleaning agent.

[0034] Corrosion inhibitors are made by the following steps:

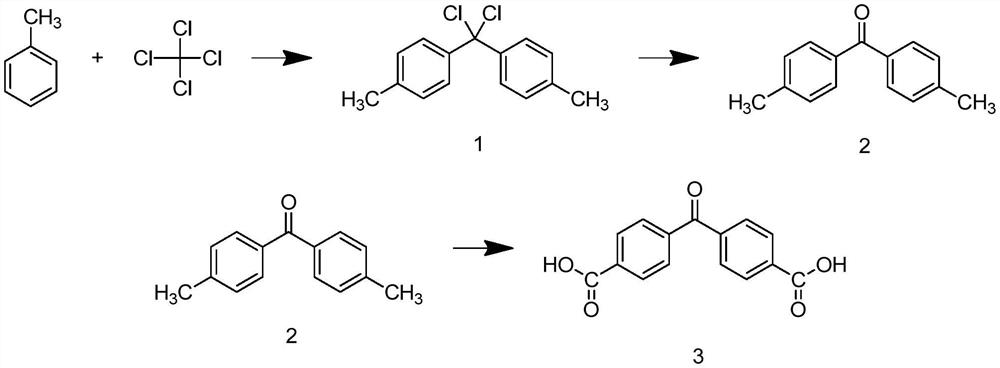

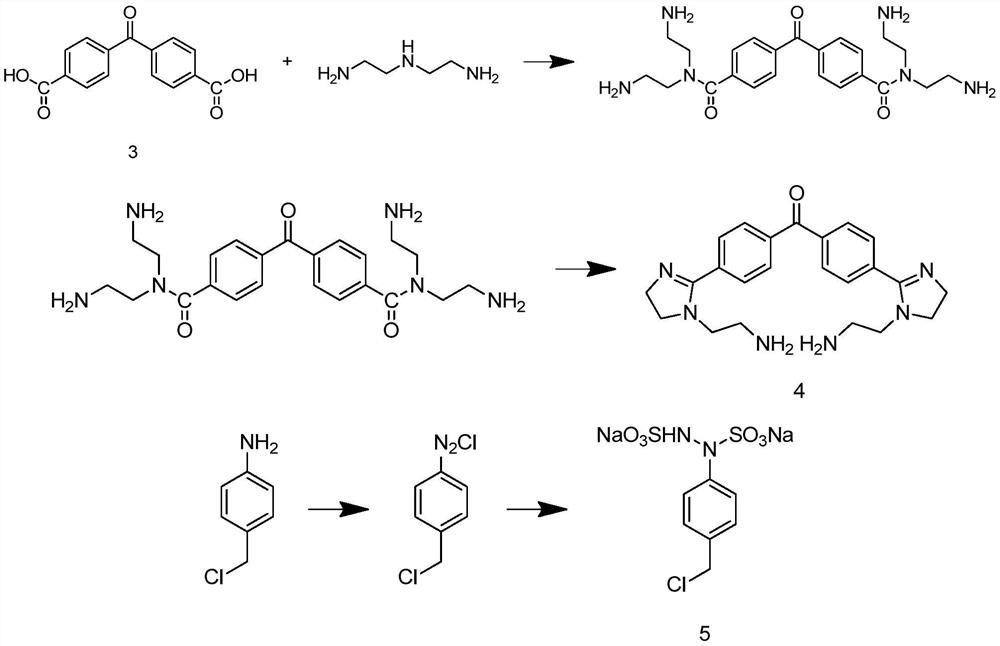

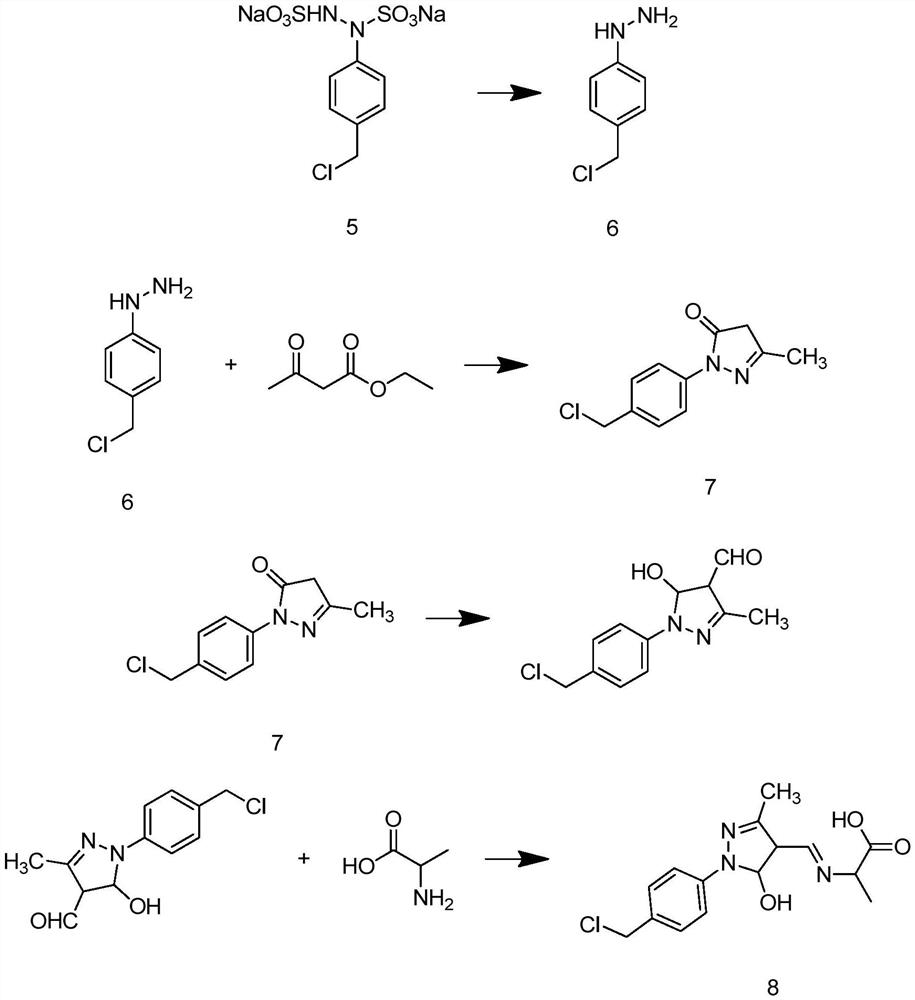

[0035] Step A1: Mix aluminum trichloride and carbon tetrachloride evenly, stir at 150r / min and 10°C, add toluene, and react for 1 hour at 40°C to prepare To obtain intermediate 1, mix intermediate 1 with deionized water, and reflux for 10 minutes at a temperature of 110° C. to obtain intermediate 2. Intermediate 2, potassium permanganate, an...

Embodiment 2

[0040] An aluminum template surface cleaning agent, comprising the following raw materials in parts by weight: 7 parts of corrosion inhibitor, 4 parts of sodium gluconate, 6 parts of acetic acid, 3 parts of sodium silicate, 3 parts of fatty acid methyl ester ethoxylate sulfonate, 45 parts of ionized water;

[0041] The aluminum template surface cleaning agent is made by the following steps:

[0042] The above raw materials were weighed, mixed, and stirred for 1.3 h under the condition of a rotating speed of 1800 r / min to prepare an aluminum template surface cleaning agent.

[0043] Corrosion inhibitors are made by the following steps:

[0044] Step A1: Mix aluminum trichloride and carbon tetrachloride evenly, stir at 180r / min, 13°C, add toluene, and react for 1.3h at 43°C. Prepare intermediate 1, mix intermediate 1 with deionized water, and reflux for 13 minutes at a temperature of 115°C to obtain intermediate 2, prepare intermediate 2, potassium permanganate, tetra-tert-but...

Embodiment 3

[0049] An aluminum template surface cleaning agent, comprising the following raw materials in parts by weight: 8 parts of corrosion inhibitor, 5 parts of sodium gluconate, 8 parts of acetic acid, 5 parts of sodium silicate, 5 parts of fatty acid methyl ester ethoxylate sulfonate, 50 parts of ionized water;

[0050] The aluminum template surface cleaning agent is made by the following steps:

[0051] The above raw materials were weighed, mixed, and stirred for 1.5 h under the condition of a rotating speed of 2000 r / min to prepare an aluminum template surface cleaning agent.

[0052] Corrosion inhibitors are made by the following steps:

[0053] Step A1: Mix aluminum trichloride and carbon tetrachloride evenly, stir at 200r / min, and add toluene at a temperature of 15°C, and react for 1.5h at a temperature of 45°C. Prepare intermediate 1, mix intermediate 1 with deionized water, and reflux for 15 minutes at a temperature of 120°C to obtain intermediate 2, prepare intermediate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com