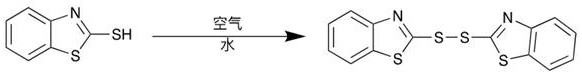

Method for producing rubber vulcanization accelerator MBTS through air oxidation

A technology of rubber vulcanization and air oxidation, applied in electrolytic organic production, electrolytic components, electrolytic processes, etc., can solve the problems of high oxygen storage and transportation, high price, high pressure resistance, and high equipment requirements, and achieves large product particles, high melting point, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Carbon is used as the anode electrode, platinum sheet is used as the cathode electrode, the voltage is set to 15V, and Zn(Ac) 2 as a catalyst, ammonia as an auxiliary agent, water as a solvent, and the reaction conditions are room temperature and normal pressure. Add 1.67 grams of 2-mercaptobenzothiazole into 5ml of water and stir continuously until it becomes a uniform slurry, and add a small amount of ammonia water (10 -4 mol) and catalyst Zn(Ac) 2 (2.19mg). Insert the carbon rod into the raw material, and at the same time blow the dry air to the carbon rod at a speed of 5m / s, power on and monitor the reaction progress under the condition of stirring. After reacting to 4 hours, the conversion rate of MBTS is about 40%. After 8 hours of reaction time, the color of the slurry changed from yellow to white and all floated on water, and the reaction was terminated to obtain 1.59 grams of white solid MBTS, with a yield of 95.6%. The initial melting point of the product d...

Embodiment 2

[0030] Carbon is used as the anode material, nickel is used as the cathode material, the voltage is set to 15V, and Zn(Ac) 2 as a catalyst, ammonia as an auxiliary agent, water as a solvent, and the reaction conditions are room temperature and normal pressure. Add 1.67 grams of 2-mercaptobenzothiazole into 5ml of water and stir continuously until it becomes a uniform slurry, and add a small amount of ammonia water (10 -4 mol) and catalyst Zn(Ac) 2 (10.95 mg). Insert the carbon rod into the raw material, and at the same time blow the dry air to the carbon rod at a speed of 5m / s, power on and monitor the reaction progress under the condition of stirring. When the reaction lasted for 3.5 hours, the conversion to MBTS was about 39.10%. After the reaction was carried out for 7 hours, the color of the slurry turned white and all floated on water, and the reaction stopped. Obtained 1.62 grams of white solid MBTS with a yield of 97.5%. The initial melting point of the product dete...

Embodiment 3

[0032] Carbon is used as the anode material, zinc is used as the cathode material, the voltage is set to 15V, and Zn(Ac) 2 as a catalyst, ammonia as an auxiliary agent, water as a solvent, and the reaction conditions are room temperature and normal pressure. Add 1.67 grams of 2-mercaptobenzothiazole into 5ml of water and stir continuously until it becomes a uniform slurry, and add a small amount of ammonia water (10 -4 mol) and catalyst Zn(Ac) 2 (21.9 mg). Connect the carbon electrode to the raw material, and at the same time blow the dry air to the carbon rod at a speed of 5m / s, power on and monitor the reaction progress under stirring conditions, and the conversion rate of MBTS is about 39.10% after 3 hours. After 6 hours, the color of the slurry turned white and all floated on water, and the reaction stopped. Obtained 1.6 grams of white solid MBTS, the conversion rate was 96.2%, and the initial melting point of the product detected by melting point apparatus was 164.3°C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com