A kind of thermal insulation and sound-absorbing material based on waste feathers and preparation method thereof

A technology of sound-absorbing materials and feathers, which is applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, instruments, etc., can solve the problems of high cost, low utilization value, and complicated keratin extraction process, and achieve Good heat preservation and sound absorption and sound insulation performance, simple and easy preparation method, and good degradable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

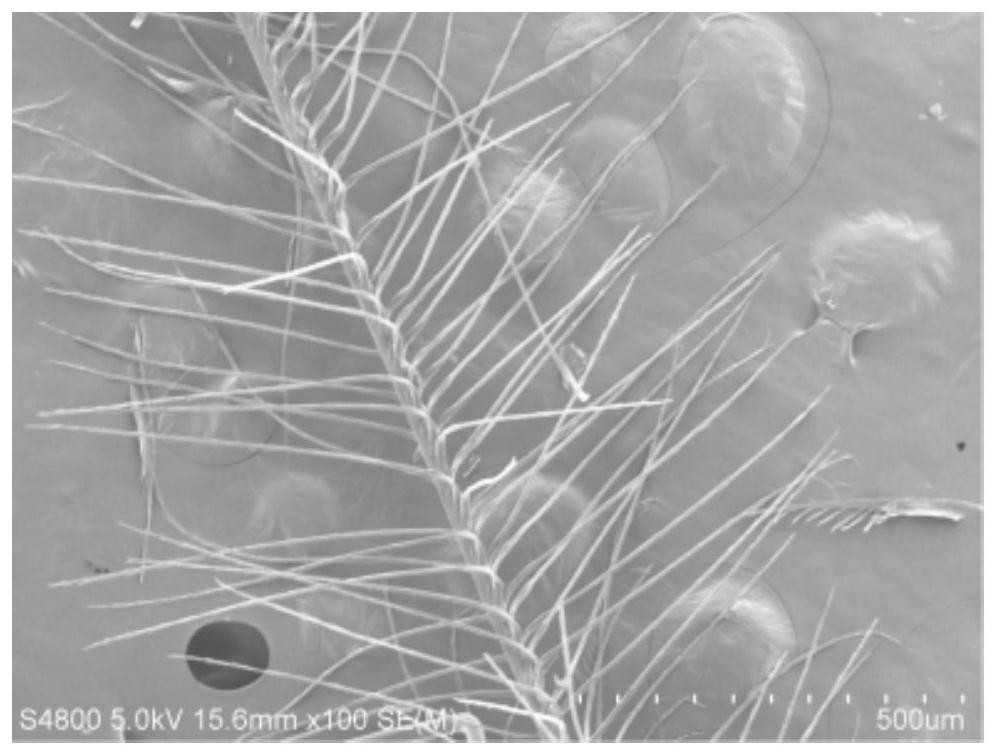

[0038] A thermal insulation and sound-absorbing material based on waste feathers, by mass percentage, the raw materials are 70% waste feathers and 30% ES fibers; the waste feathers are in the form of single fibers, that is, in the form of tufts, without tufts, and have a length of 15%. -18mm, the diameter is 20-24μm; the ES fiber is a concentric sheath-core type, the fiber fineness is 2.2dtex, and the fiber length is 38mm.

[0039] 1) adding the waste feathers of 50g to 1000mL massfraction is that in the sodium dodecyl sulfonate aqueous solution of 2% and dispersing by mechanical stirring, obtains waste feather dispersion solution;

[0040] 2) the ES fiber of 21.5g is added to the feather dispersion solution obtained in step 1) after opening by the opening machine, and the glutaraldehyde of 60g is weighed and added to the dispersion solution simultaneously, and the fiber mixture is obtained by mechanical stirring;

[0041] 3) sending the fiber mixture obtained in step 2) into ...

Embodiment 2

[0046] A thermal insulation and sound-absorbing material based on waste feathers, by mass percentage, the raw materials are 60% waste feathers and 40% ES fibers; the waste feathers are in the form of single fibers, that is, in the form of fluff branches, without fluff structure, and the length is 12 -15mm, the diameter is 25-28μm; the ES fiber is a concentric sheath-core type, the fiber fineness is 2.4dtex, and the fiber length is 35mm.

[0047] 1) adding the waste feathers of 60g to 1800mL massfraction is that in the 5% cetyltrimethylammonium bromide aqueous solution and dispersing by mechanical stirring, obtains waste feather dispersion solution;

[0048] 2) the ES fiber of 40g is added to the feather dispersion solution obtained in step 1) after the use of the open feeder to open, and the glutaraldehyde of 180g is weighed and added to the dispersion solution simultaneously, and the fiber mixture is obtained by mechanical stirring;

[0049] 3) sending the fiber mixture obtai...

Embodiment 3

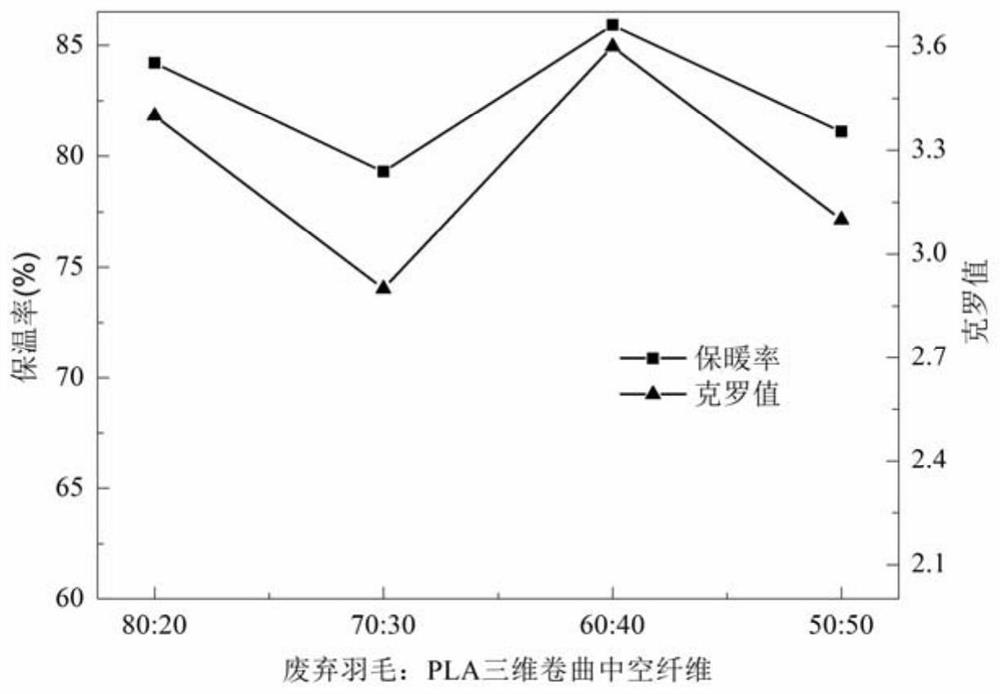

[0054] A thermal insulation and sound-absorbing material based on waste feathers, according to the mass percentage, the raw materials are 80% waste feathers and 20% PLA three-dimensional crimped hollow fibers; the waste feathers are in the form of single fibers, that is, in the form of velvet branches, without a velvet flower structure, The length is 16-20 mm, and the diameter is 20-25 μm; the PLA three-dimensional crimped hollow fiber has a fiber fineness of 2.0 dtex and a fiber length of 38 mm.

[0055] 1) adding the waste feathers of 50g to 1000mL massfraction is that in the 4% cetyltrimethylammonium bromide aqueous solution, dispersed by mechanical stirring, obtains waste feather dispersion solution;

[0056] 2) 12.5g of PLA three-dimensional crimped hollow fibers are added to the feather dispersion solution obtained in step 1) after the PLA three-dimensional crimped hollow fiber is opened by an open feeder, and 100g of transglutaminase is weighed into the dispersion soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com