Hollow plate ceramic filter membrane and preparation method thereof

A technology for a ceramic filter membrane and a ceramic membrane support body is applied in the field of porous ceramic materials, which can solve the problems of low strength and easy breakage, and achieve the effects of reducing the cost of raw materials, reducing the amount of water added, and improving the flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention at first provides the preparation method of hollow flat ceramic filter membrane, comprises the following steps:

[0036] a. Preparation of hollow flat ceramic support body:

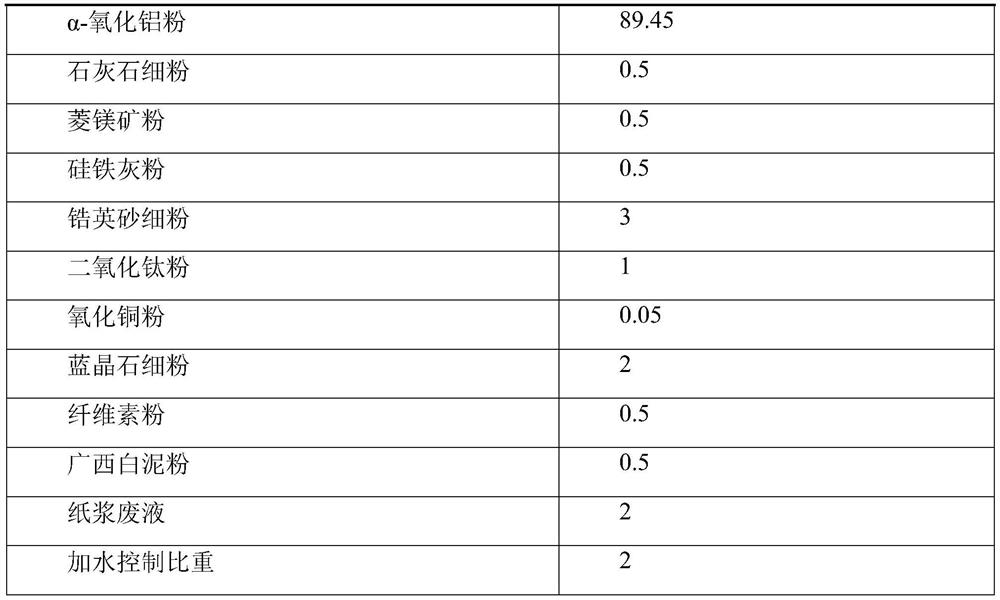

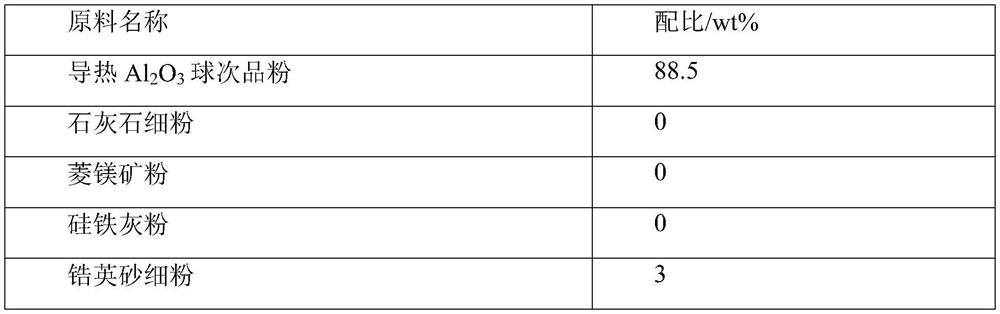

[0037] (1) Raw materials: the main raw material is thermal conductivity Al 2 o 3 Ball defective products, alumina content ≥ 99%, particle size < 0.044mm;

[0038] The flux is a mixture composed of limestone powder, magnesite powder, and ferrosilicon ash powder: among them, the calcium carbonate content in limestone powder is ≥99%, the particle size is <0.088mm, and the magnesium carbonate content in magnesite is ≥99%, Particle size < 0.088mm, silicon dioxide content in ferrosilicon ash powder ≥ 98%, particle size < 0.044mm;

[0039] The phase change enhancer is zircon sand powder, in which ZrO 2 Content ≥ 55%, particle size < 0.088mm;

[0040] The sintering agent is a composite of titanium dioxide powder and copper oxide powder, in which TiO 2 Content ≥ 99%, particle siz...

Embodiment 1

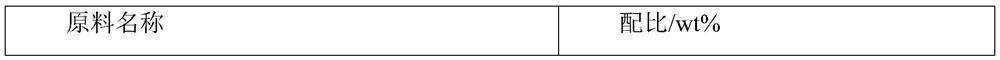

[0074] (1) Preparation of ceramic membrane support

[0075] Accurately weigh each raw material according to the ratio in Table 1. First pour the powdered raw materials into the forced mixer, dry mix for 10 minutes, add water and wet mix for 8 minutes, pour the mud into the mud for 30 minutes, and finally put the mud into a sealed tank Stale for 24 hours. It is prepared by extrusion molding method, processed according to the designed hollow plate size and installed with an extrusion mold, extruded at room temperature, the molding pressure is 40MPa, and cut into the required size according to the user's requirements. The cut body is first dried naturally at room temperature for 24 hours, and then sent to the tunnel drying kiln for drying. The maximum drying temperature of the tunnel drying kiln is controlled at 300 ° C, and the drying time is controlled at 8 hours. The dried semi-finished hollow flat ceramic membrane support is fired in a shuttle kiln, the firing temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com