Process for producing pyrroloquinoline quinone disodium salt by fermentation method

A technology of pyrroloquinoline quinone disodium salt and fermentation method, which is applied in the direction of fermentation, biochemical instruments, sterilization methods, etc., to achieve the effect of prolonging the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The embodiment of the present invention provides a process for producing pyrroloquinoline quinone disodium salt by fermentation, comprising the following steps:

[0030] Step 1. Proliferation: Inoculate the original bacterial species methylotrophic bacteria Methylovorus sp.MP688 into the bacterial basal medium, add dihydrogen phosphate ion and monohydrogen phosphate ion on the 1b basic machine to adjust the pH of the bacterial basal medium to 6.5 ~7.0, lb medium uses tryptone (Tryptone) 10g / L, yeast extract (Yeast extract) 5g / L, sodium chloride (NaCl) 10g / L, through this medium to expand the population of methylotrophic bacteria MP688 .

[0031] Step 2. Cultivation: After culturing the bacterial basal medium for 4 to 7 days, add the fermentation broth, and then stir it into a slurry to make it easy to mix with the fermentation broth. The methylotroph MP688 is evenly distributed, and then placed in the fermenter 1, 5, and add a sufficient amount of fermentation broth to...

Embodiment 2

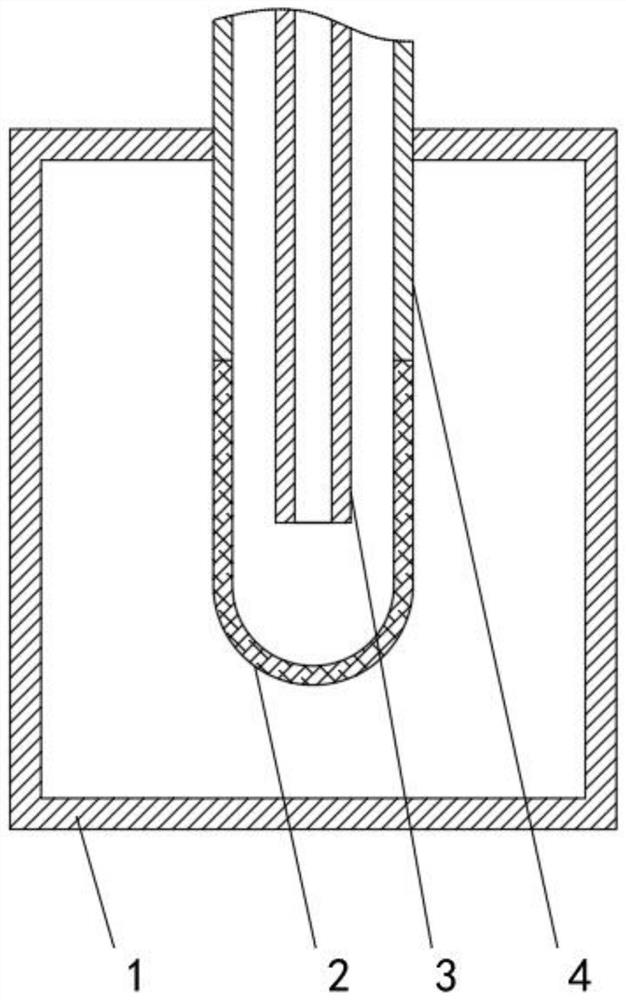

[0039] This embodiment is the structure of a fermenting device in Embodiment 1: the fermenter 1 is interspersed with an outer tube 4 , the lower end of the outer tube 4 is fixedly connected with a microfiltration membrane 2 , and an inner tube is arranged inside the outer tube 4 . During the fermentation process, that is, the pyrroloquinoline quinone and metabolites produced in the proliferation and production of methylotrophic bacteria MP688 pass through the microfiltration membrane 2 and enter the interior of the outer tube 4, while the nutrients inside the outer tube 4 enter the fermenter 1 In the fermented stock solution, the inner tube 3 is injected with fresh fermented broth at this time, and material replacement occurs at the microfiltration membrane 2, and the replaced fresh fermented broth is discharged and collected from the outer tube 4 for extracting pyrroloquinoline quinone.

[0040] In addition, there are equipments that can ensure the normal proliferation and gro...

Embodiment 3

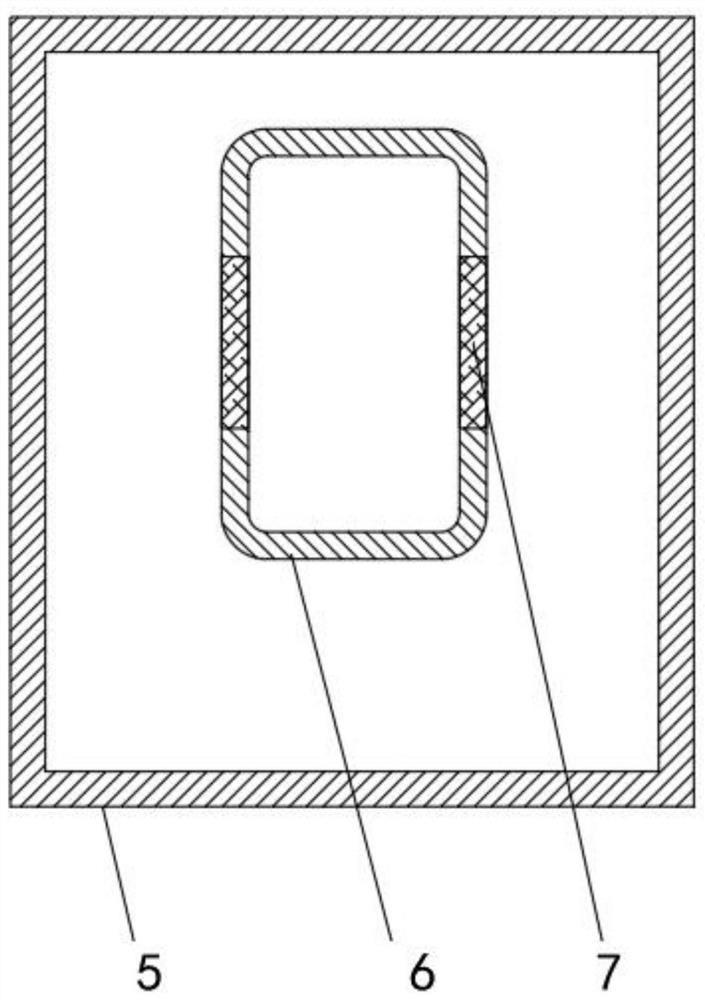

[0042]This embodiment is the structure of another fermentation device in Embodiment 1: a liquid storage container 6 is provided inside the fermenter 5, and a microfiltration membrane 7 is provided on the side wall of the liquid storage container 6, and the liquid storage container 6 is equipped with Into fresh fermented liquid, and liquid storage container 6 is placed in fermentor 5, and the pyrroloquinoline quinone and metabolite that produce in the multiplication production of methylotrophic bacteria MP688 pass through microfiltration membrane 7 and enter the inside of outer tube 4, simultaneously Nutrients in the liquid storage container 6 enter the fermentation stock solution in the fermenter 5 . Regularly take out the liquid storage container 6 and replace it with fresh fermented liquid, the original one is used to extract pyrroloquinoline quinone

[0043] In addition, there are equipments that can ensure the normal proliferation and growth of methylotrophic bacteria MP68...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com