Integrated optics-based pressure sensor capable of being customized quickly and customization method

A pressure sensor and integrated optics technology, applied in the direction of fluid pressure measurement using optical methods, can solve problems such as rising production costs, and achieve the effect of breaking through the upper limit of pressure, quickly customizing the range, and realizing ultra-high sensitivity pressure measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

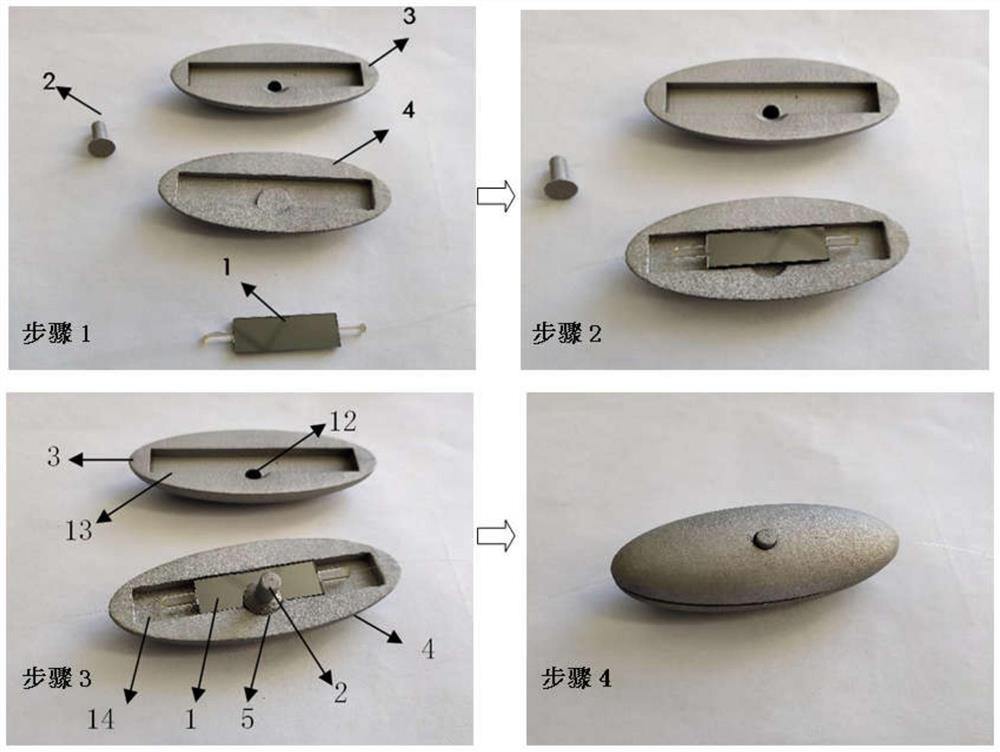

[0057] A pressure sensor with a range of 0-80 MPa based on a pressure block and a Mach-Zehnder structure, the sensor includes a pressure-bearing shell, a pressure block 2 and an optical chip 1 based on a Mach-Zehnder structure;

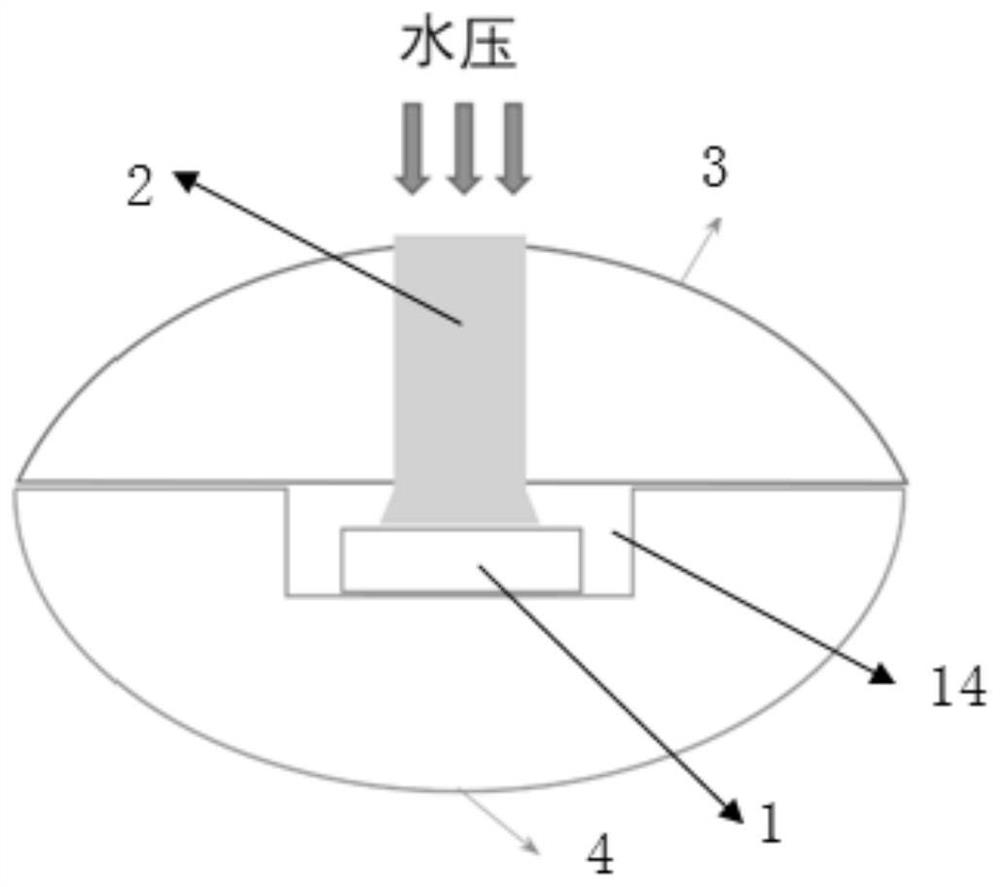

[0058] The pressure shell includes an upper pressure shell 3 and a lower pressure shell 4. The upper pressure shell 3 is provided with an upper groove 13, and the lower pressure shell 4 is provided with a lower groove 14. One side of the lower groove 14 A pressure block fixing groove 5 is provided,

[0059] The optical chip 1 is fixed in the lower groove 14, the optical chip 1 is provided with a pressure block 2, the pressure block 2 is embedded in the pressure block fixing groove 5, and penetrates the upper pressure-bearing shell 3 through the pressure block penetration hole 12;

[0060] The upper bottom surface of the pressure block 2 is used to contact the pressure to be measured; the lower bottom surface of the pressure block 2 is used to contact ...

Embodiment 2

[0076]A method for customizing a pressure sensor with a range of 0-120 MPa based on a pressure block and a Mach-Zehnder structure, the measurement system is the same as that in Embodiment 1, and the parameters and characteristics of the optical chip 1 are also the same.

[0077] In this embodiment, the pressure block 2 is manufactured by traditional metal processing. Traditional metal processing methods include turning and cutting processes. The cost of traditional machining is lower, and the development cycle is very short. With special machine tools and workers, the daily output can reach hundreds of pieces.

Embodiment 3

[0079] Embodiment 1 provides a method for customizing a pressure sensor based on a pressure block and a Mach-Zehnder structure with a range of 0-80 MPa, the method comprising:

[0080] Customize the maximum range A of the pressure sensor according to your needs 1 , calculate the sensitivity design value of the required custom pressure sensor

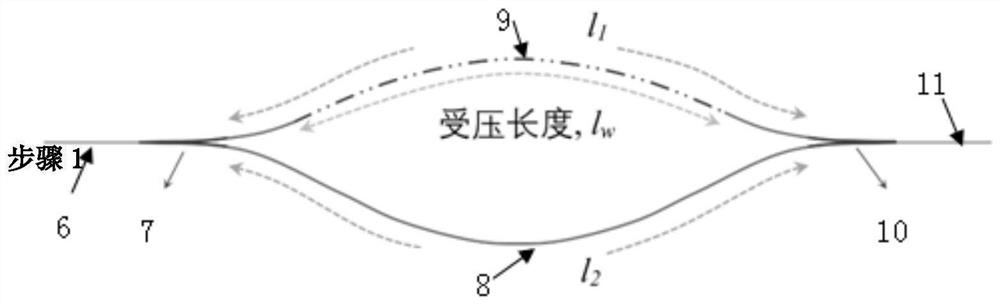

[0081] The measurement system used includes a wide-spectrum light source, an optical chip 1 and a spectrometer. The spectral range of the broadband light source is 1530-1570nm. The waveguide material of the optical chip 1 is silicon dioxide, and the cross-section of the waveguide is 4 μm 2 square, the core / cladding refractive indices are 1.47459 and 1.4448, respectively. The structure of the optical chip 1 is as figure 2 As shown, the length of the short interference arm 9 is 20 mm, and the length of the long interference arm 8 is 20 mm+82.68 μm. At 1550 nm, the effective refractive index of the waveguide is 1.4622. At this time, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com