Production process for preparing regenerated board from recycled waste phenolic plastic

A technology of phenolic plastics and production process, which is applied in the field of recycling waste phenolic plastics, can solve the problems of unfavorable promotion and use of recycling methods, and achieve the effects of sustainable utilization, performance improvement, and mass recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This example proposes a production process for recycling waste phenolic plastics to prepare recycled boards, which is based on the mechanical crushing and recycling method, through which the waste phenolic plastics are partially decrosslinked by mechanical force, and the surface is activated to restore the plasticity of the part, so that it can be added A recycling process in which new materials are remolded into recycled boards.

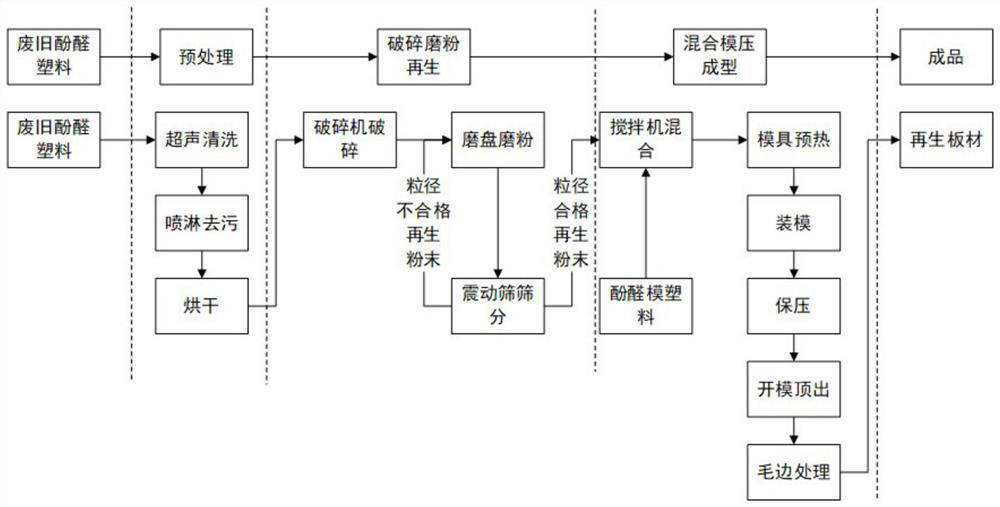

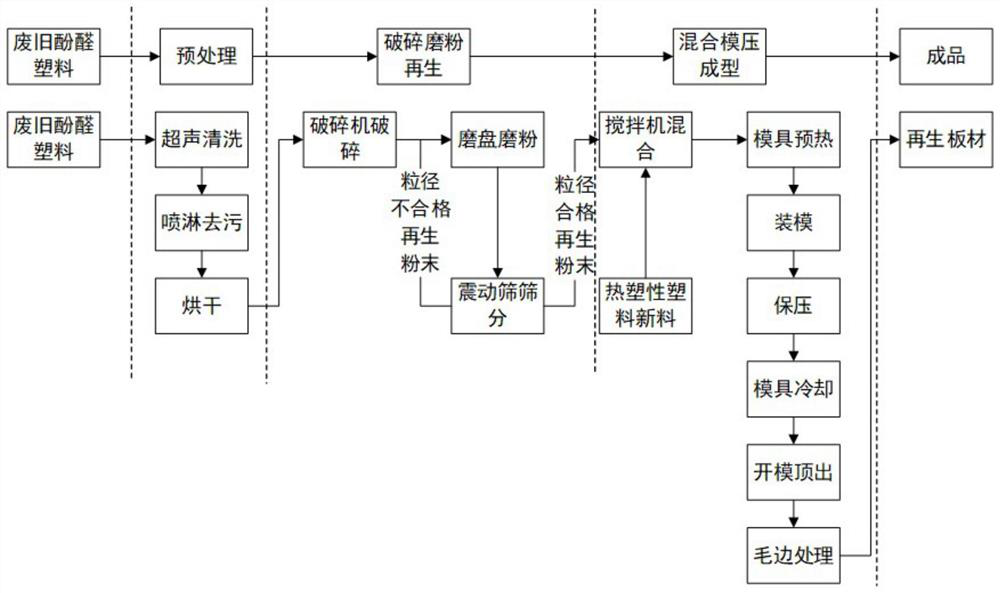

[0029] Please combine figure 1 and figure 2 , The production process includes the following processes: pretreatment, crushing and grinding treatment and mixed molding treatment.

[0030] Pretreatment is used to dry the waste phenolic plastic after cleaning. In this embodiment, first put the waste phenolic plastic into an ultrasonic water tank for ultrasonic cleaning to remove surface stains, then perform spray washing, and finally dry by drying equipment to remove surface moisture. For waste phenolic plastics, you can choose the defective...

Embodiment 2

[0038] This embodiment discloses a production system for recycling waste phenolic plastics to prepare recycled boards, which is used to remake waste phenolic plastics into recycled boards; the production system includes a cleaning and drying unit and a milling unit in sequence according to the processing process and hybrid compression molding units.

[0039] The cleaning and drying unit is used to clean the waste phenolic plastics first, and then dry the cleaned waste phenolic plastics. In this embodiment, the cleaning process includes two steps of ultrasonic cleaning and water washing. Specifically, the waste phenolic plastics are put into the cleaning and drying machine, and first transported to the ultrasonic water tank by the conveyor belt for ultrasonic cleaning to remove the stains on the surface, and then transported to the spraying machine. It is further cleaned in the shower system, and finally passed through the drying system to remove the moisture on the surface.

...

Embodiment 3

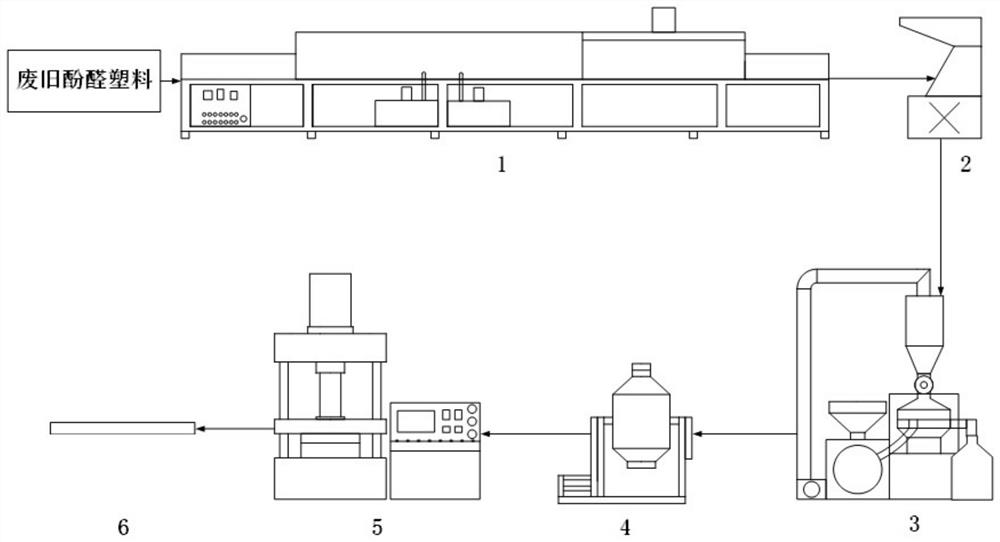

[0044] see image 3 , this embodiment discloses a production equipment for recycling waste phenolic plastics to prepare recycled boards. The first half of the washing and drying machine 1 cleans the waste phenolic plastics to remove the surface stains of the waste phenolic plastics, and the second half dries the cleaned waste phenolic plastics; the crusher 2 breaks the cleaned and dried waste phenolic plastics into small particles; Machine 3 grinds waste phenolic plastic particles, breaks the cross-linked and solidified molecular chains of waste phenolic plastics, destroys the cross-linked structure in waste phenolic plastics, and activates the surface of the powder. There is a magnetic separation mechanism at the entrance of the mill , to screen out the waste plastic particles with metal, and there is a vibrating screen at the outlet, which can screen the powder that meets the particle size requirement into the storage tank, and the powder that does not meet the target is tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap