Bacillus amyloliquefaciens and application thereof in soy sauce fermentation

A technology of amylolytic spores and bacillus, applied in the direction of bacteria, microorganism-based methods, microorganisms, etc., can solve the problem that the amino acid production rate exceeds 65%, and achieve the effect of outstanding umami taste and mellow taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] (1) Preparation of seed liquid: culturing Bacillus amyloliquefaciens YB-18 in the seed medium to obtain the seed liquid;

[0041] (2) Expansion cultivation: Bacillus amyloliquefaciens YB-18 seed liquid is according to 10 2 -10 4 The inoculum amount of each / g koji is inoculated into soy sauce koji, and the koji is made at a constant temperature to obtain soy sauce koji;

[0042] (3) The soy sauce koji obtained in step (2) is mixed with salt water, and fermented at constant temperature.

[0043] further,

[0044] The seed culture medium comprises the following components in mass fractions: 10-15% of soy sauce crude oil, 3-6% of glucose and 1-2% of edible salt. Preferably, the soy sauce crude oil is a soy sauce crude oil with a mass volume concentration of ammonia nitrogen of 1.0 g / 100 mL.

[0045] further,

[0046] Cultivate 24-30h in seed culture medium to obtain seed liquid in described step (1);

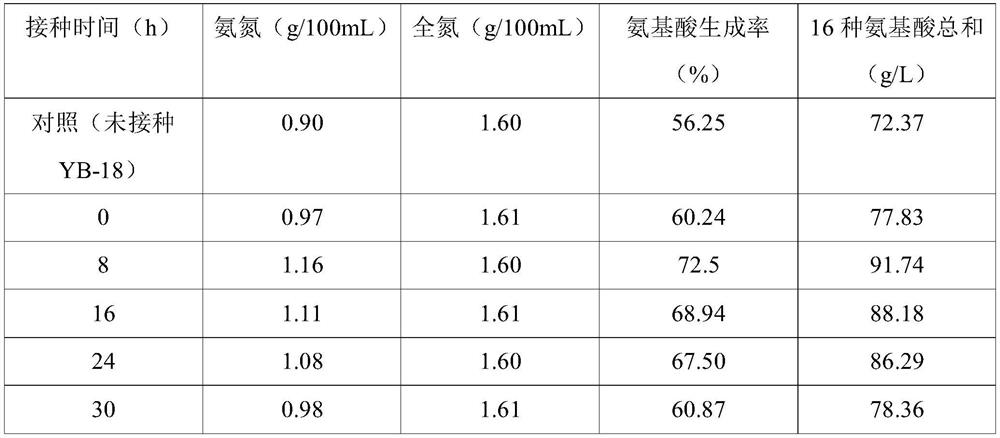

[0047] Further, in the step (2), the koji is prepared at a constan...

Embodiment 1

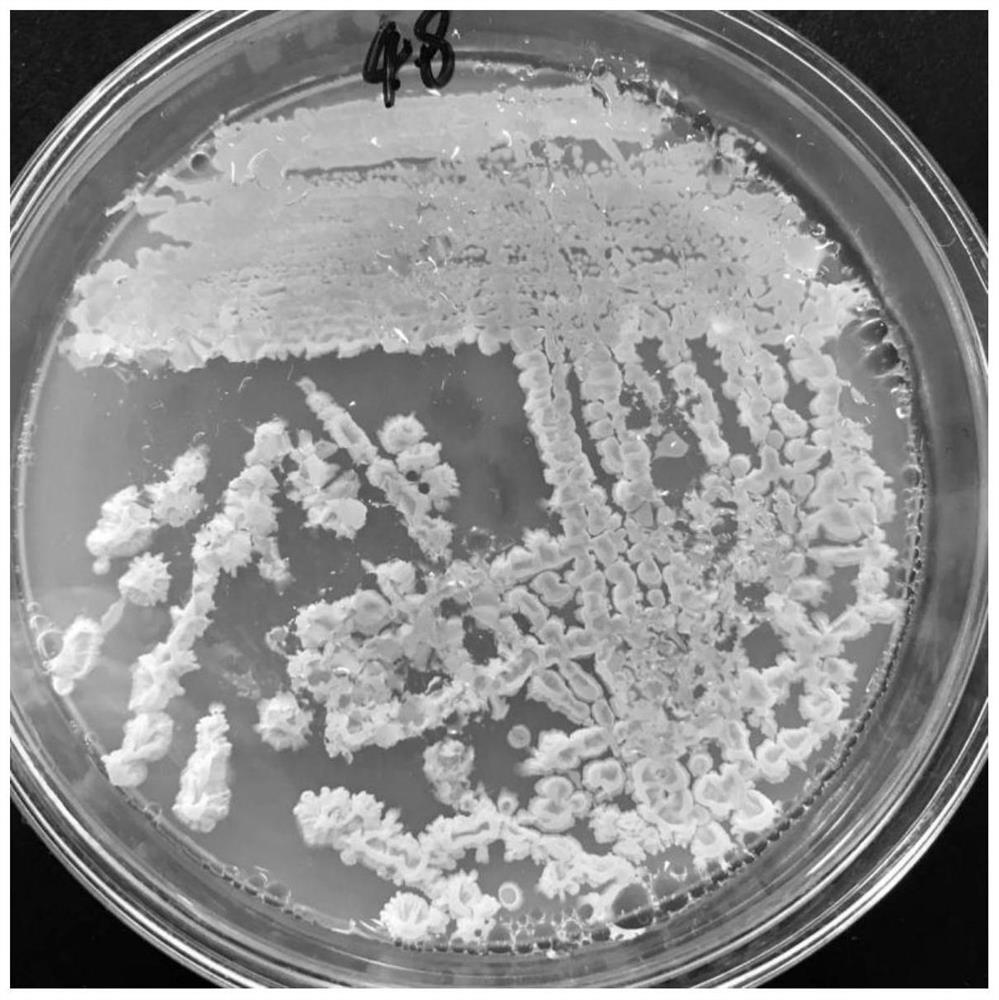

[0052] Screening of High Aminopeptidase Strains

[0053] Take 20g of soy sauce koji, grind it, and then add a certain amount of sterile saline to dilute in proportion to 10 -1 、10 -2 、10 -3 、10 -4 、10 -5 、10 -6 concentration.

[0054] Take 0.1 mL of the diluted solution and spread it evenly in the selective medium, and culture it at 37°C for 1-2 days. During the cultivation process, observe the growth of the colony, the speed and size of the transparent circle formation, and measure the circle-to-diameter ratio. According to the above method, a total of 156 colonies with obvious transparent circles were screened out, among which 35 strains were particularly prominent.

[0055] Inoculate 35 more prominent colonies into LB slant medium, culture at 37°C for 2-3 days, and number YB1-YB35 respectively.

[0056] The selective medium contains 0.02 g / L of L-leucine-4-nitroaniline, 20 g / L of glucose, 3 g / L of yeast powder, 3 g / L of peptone, and 15-20 g / L of agar powder.

Embodiment 2

[0058] Breeding of Bacillus amylolyticus YB-18 with high aminopeptidase

[0059] The obtained 35 particularly significant strains were inoculated into a liquid medium and cultured at 37°C for 3 days. The components of the liquid medium were corn steep liquor 10g / L, bran 30g / L, MgSO 4 ·7H 2 O 0.2g / L, KH 2 PO 4 4g / L, CaCl 2 0.5g / L, the pH of the liquid medium is 6.5.

[0060] After the cultivation, the aminopeptidase activity of each strain was measured. The method of aminopeptidase determination was as follows: dilute the fermentation filtrate several times, take 0.4mL of the diluted solution and add it to 6mL of Tris-Hcl buffer solution with a pH value of 8.0, at 40°C Preheat the water bath for 5 minutes, then add 0.4mL 26mM L-leucine-4-nitroaniline ethanol solution (add distilled water as the control), react for 10 minutes, put it into the ice bath immediately, and measure the color at the wavelength of 405nm after 5 minutes. Under the condition of 40°C and pH value of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com