Nitrogen-doped carbon microcubes derived from metal organic framework as well as preparation method and application of nitrogen-doped carbon microcubes

A metal-organic framework and cube technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, hybrid capacitor electrodes, etc., can solve the problems of complex preparation methods, and achieve simple preparation methods, high specific surface area, and good scalability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

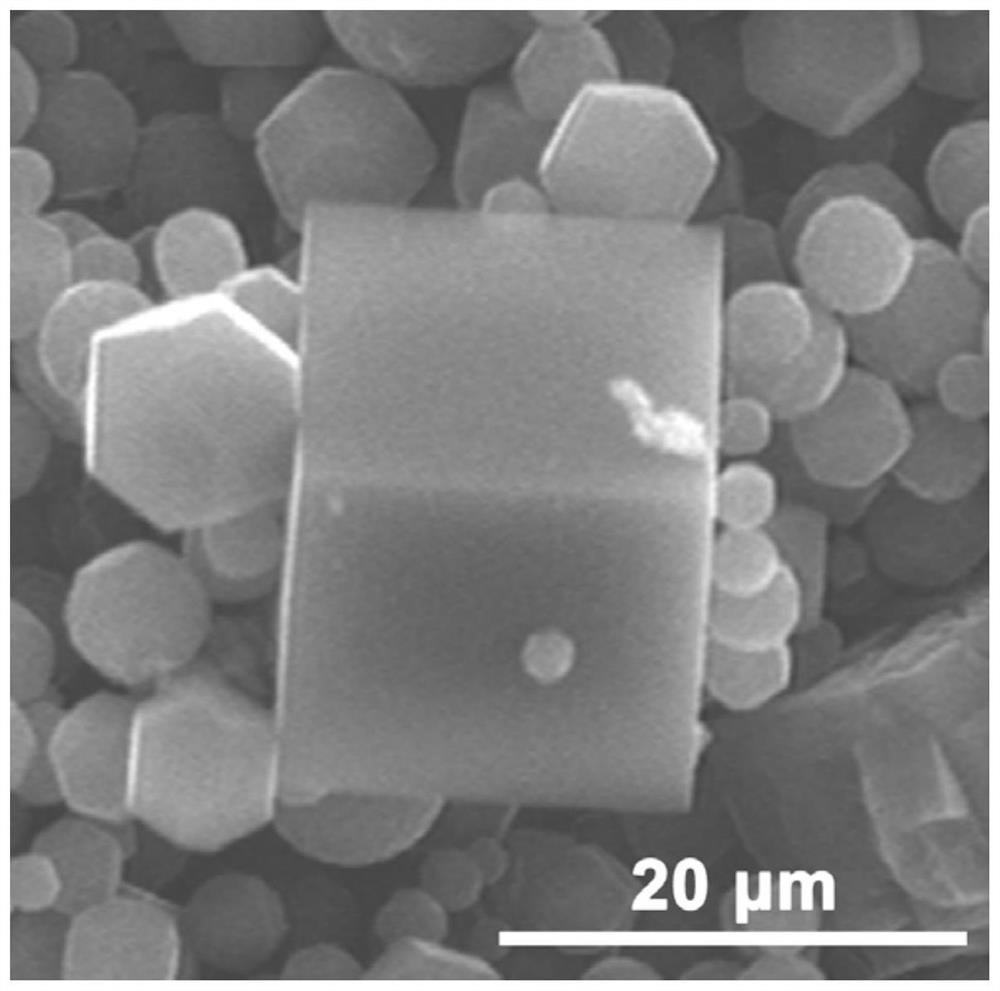

Embodiment 1

[0037] (1) Add 0.5 g of K30 into the beaker, then pour 45 mL of DMF, and stir until K30 is completely dissolved to obtain a uniform solution;

[0038] (2) Add 300 mg of zinc nitrate and 50 mg of terephthalic acid into the solution of (1), continue stirring until completely dissolved to obtain a uniform solution, and then transfer the solution to a 50 mL high-temperature reaction kettle ;

[0039] (3) Put the reaction kettle with the solution in an oven for solvothermal reaction at 165 °C for 22 hours;

[0040] (4) Wash the sample after solvothermal reaction with ethanol and centrifuge to obtain a light yellow precipitate, put the precipitate in an oven at 60 °C, and dry it for more than 24 hours;

[0041] (5) After grinding and dispersing the dried light yellow powder, put it in a ceramic boat, put the porcelain boat in a tube furnace, and after 20 minutes of nitrogen gas, raise the temperature to 900 °C with a heating rate of 5 °C / min , kept at room temperature for 10 hours...

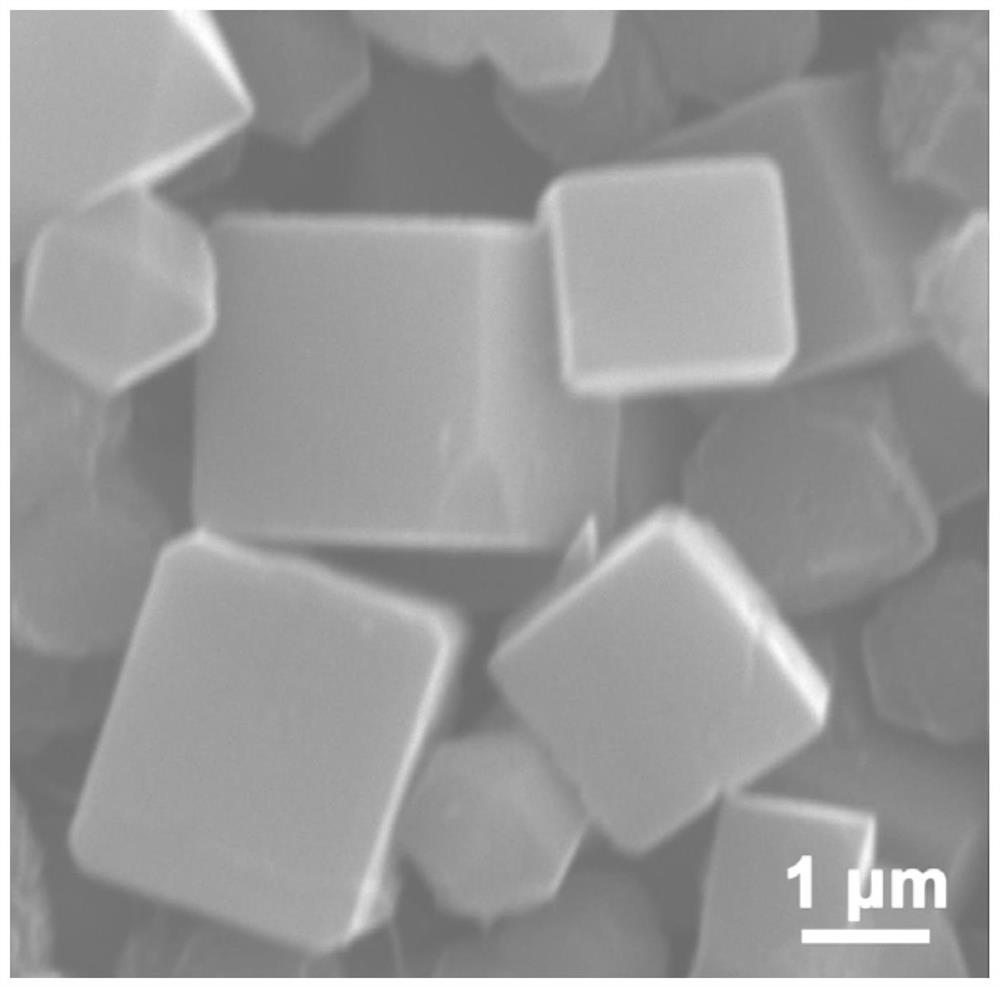

Embodiment 2

[0045] (1) Add 1.5 g of K30 into the beaker, then pour 40 mL of DMF, and stir until K30 is completely dissolved to obtain a uniform solution;

[0046] (2) Add 400 mg of zinc nitrate and 50 mg of aminoterephthalic acid into the solution of (1), continue to stir until completely dissolved to obtain a uniform solution, and then transfer the solution to a 50 mL high-temperature reactor middle;

[0047] (3) Put the reaction kettle with the solution in an oven for solvothermal reaction at 175 °C for 12 hours;

[0048] (4) Wash the sample after solvothermal reaction with ethanol and centrifuge to obtain a light yellow precipitate, put the precipitate in an oven at 60 °C, and dry it for more than 24 hours;

[0049] (5) After grinding and dispersing the dried light yellow powder, put it in a ceramic boat, put the porcelain boat in a tube furnace, and after passing nitrogen for 20 minutes, raise the temperature to 1500 °C with a heating rate of 10 °C / min , kept warm for 1 hour, and na...

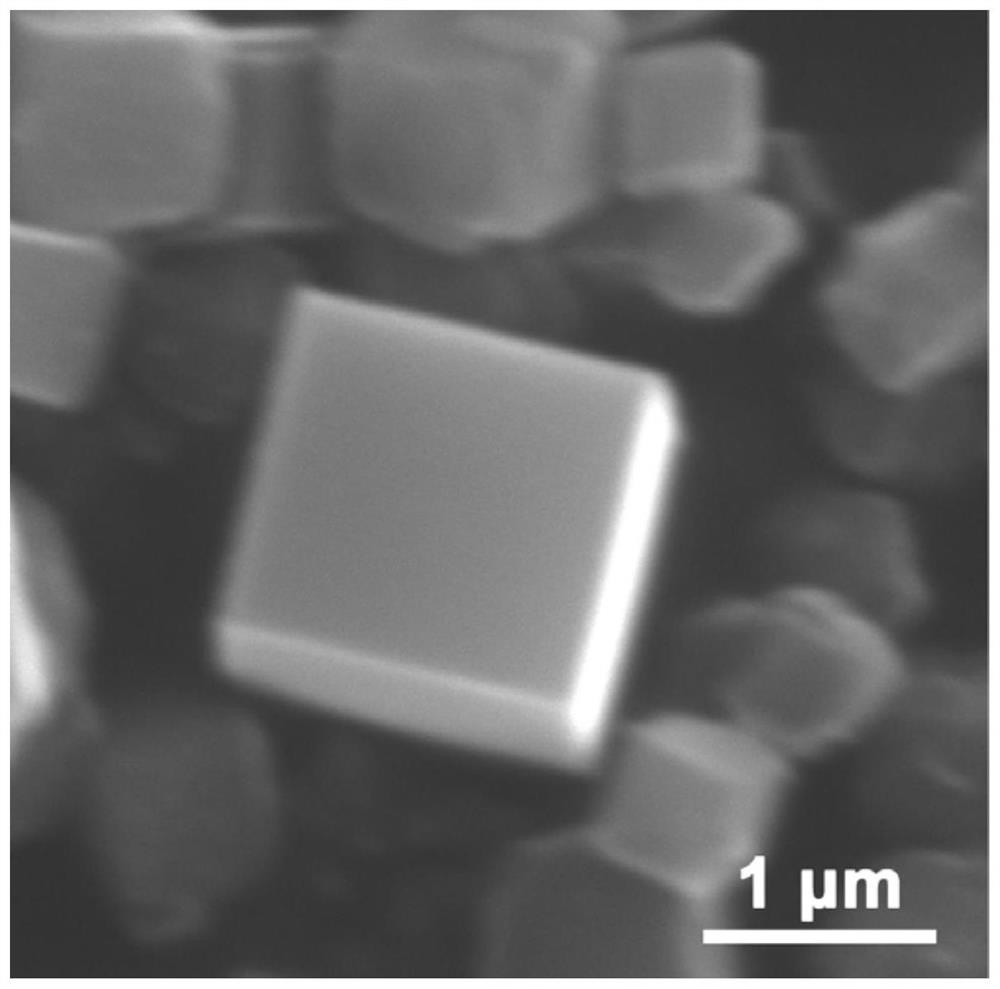

Embodiment 3

[0053] (1) Add 1 g of K30 into the beaker, then pour 30 mL of DMF, and stir until K30 is completely dissolved to obtain a uniform solution;

[0054] (2) Add 450 mg of zinc nitrate and 180 mg of aminoterephthalic acid into the solution of (1), continue to stir until completely dissolved to obtain a uniform solution, and then transfer the solution to a 50 mL high-temperature reaction kettle middle;

[0055] (3) Put the reaction kettle with the solution in an oven, and conduct a solvothermal reaction at 180 °C for 8 hours;

[0056] (4) Wash the sample after solvothermal reaction with ethanol and centrifuge to obtain a light yellow precipitate, put the precipitate in an oven at 60 °C, and dry it for more than 24 hours;

[0057] (5) After grinding and dispersing the dried light yellow powder, put it in a ceramic boat, put the porcelain boat in a tube furnace, and after passing in nitrogen for 20 minutes, raise the temperature to 900 °C with a heating rate of 6 °C / min , kept warm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com