Carbon nanotube cold cathode electron source and alignment welding method thereof

A carbon nanotube and welding method technology, which is applied in the field of carbon nanotube cold cathode electron source and its alignment welding, can solve the problems of shortened life, shedding of substrate, and quality of emitted electron beam, etc., and achieves the effect of reducing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] This embodiment provides a method for parasite welding of a carbon nanotube cold cathode electron source, and the parasite welding method includes the following steps:

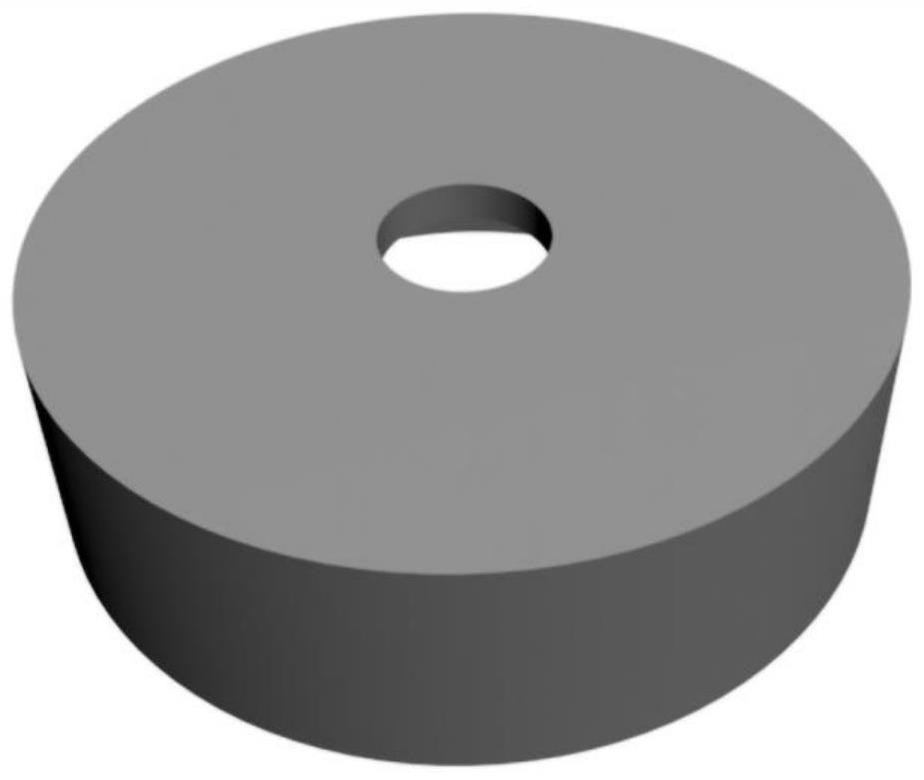

[0088] (1) Take a circular stainless steel with a diameter of 10 mm and a thickness of 500 μm polished on one side as the first substrate, ultrasonically clean it with acetone and isopropanol for 15 minutes, and dry it with nitrogen; spin coat a layer of electron beam glue , developed by electron beam etching process, and etched at the center of the first substrate to expose an elliptical region with a long axis of 1000 μm to 2000 μm and a short axis of 250 μm to 1000 μm; using metal Al and Fe as deposition sources, electron beam evaporation Plating technology vapor-deposits 10nm-thick Al and 2nm-thick Fe in the central area of the first substrate as the catalyst layer required for the growth of carbon nanotubes, and then removes excess electron beam glue; finally puts the first substrate with the cata...

Embodiment 2

[0096] This embodiment provides a parasite welding method for a carbon nanotube cold cathode electron source, except that in step (1), a circular array with a diameter of 60 μm and a pitch of 100 μm is etched at the center of the first substrate , which generally occupy the long axis of 1000 μm ~ 2000 μm, except for the elliptical region of 250 μm ~ 1000 μm short axis, the rest are the same as in Example 1.

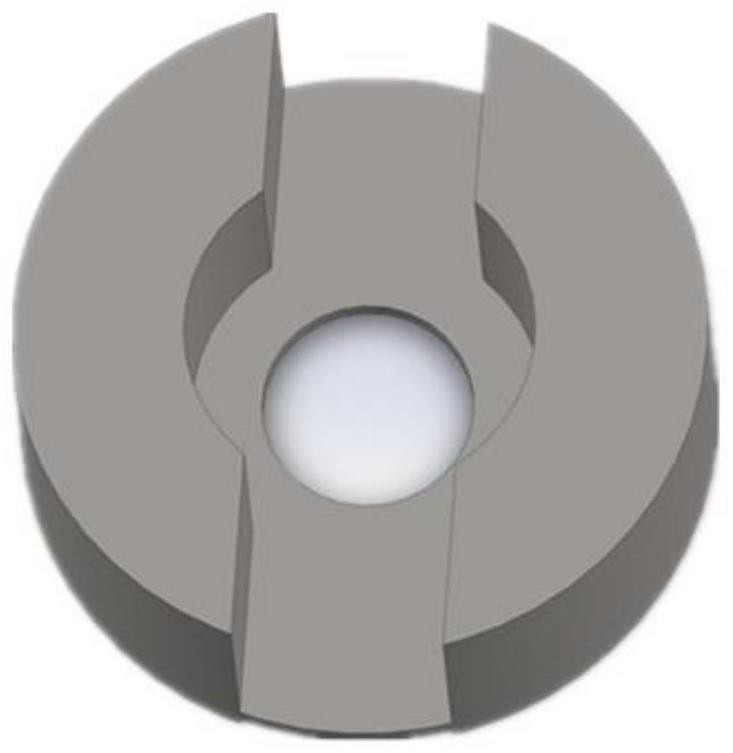

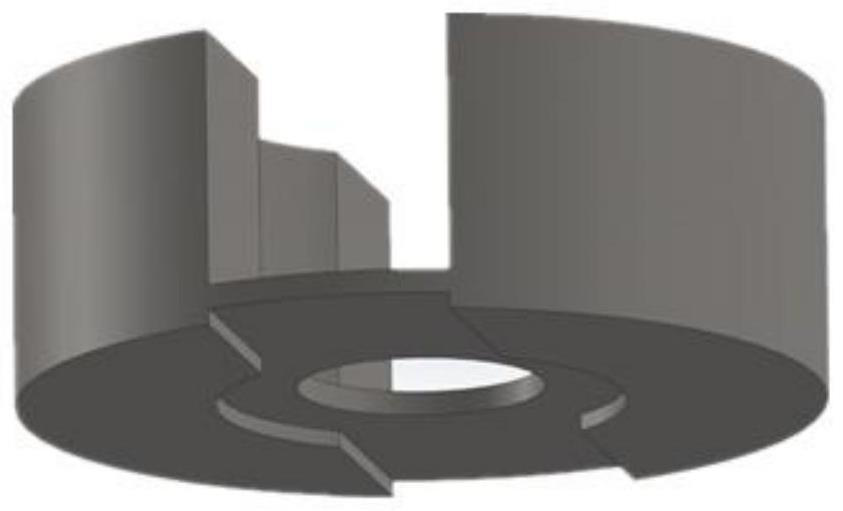

[0097] The carbon nanotube cold cathode electron source obtained in this embodiment is a carbon nanotube array cold cathode electron source, and its schematic diagram is as follows Figure 11 As shown, its SEM image is shown in Figure 12 It can be seen that the morphology of the carbon nanotubes can still maintain the complete morphology before welding after the cold cathode electron source of the carbon nanotube thin film is welded. The carbon nanotube array cold cathode electron source includes a cathode substrate 9 and a carbon nanotube array 10 welded on the surface...

Embodiment 3

[0099] This embodiment provides a method for parasite welding of a carbon nanotube cold cathode electron source, and the parasite welding method includes the following steps:

[0100] (1) Take a circular stainless steel with a diameter of 10 mm and a thickness of 800 μm polished on one side as the first substrate, ultrasonically clean it with acetone and isopropanol for 15 minutes, and dry it with nitrogen; spin coat a layer of electron beam glue , developed by electron beam etching process, etched in the center of the first substrate to expose a circular area with a diameter of 1.2mm; using metal Al and Fe as deposition sources, using electron beam evaporation technology to evaporate the central area of the first substrate 0.8nm thick Al and 0.2nm thick Fe are used as the catalyst layer required for the growth of carbon nanotubes, and then the excess electron beam glue is removed; finally, the first substrate evaporated with the catalyst layer is put into the plasma chemical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com