A flocculation flotation method for comprehensive recovery of fine-grained molybdenum from iron tailings

A technology of micro-grain and iron tailings, applied in the direction of selective deposition, solid separation, etc., can solve the problems of low concentration of overflow slurry from iron dressing tailings, unsatisfactory recovery index of target minerals, etc., and achieve optimal flotation index, Improve the effect of flotation and increase the concentration of flotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

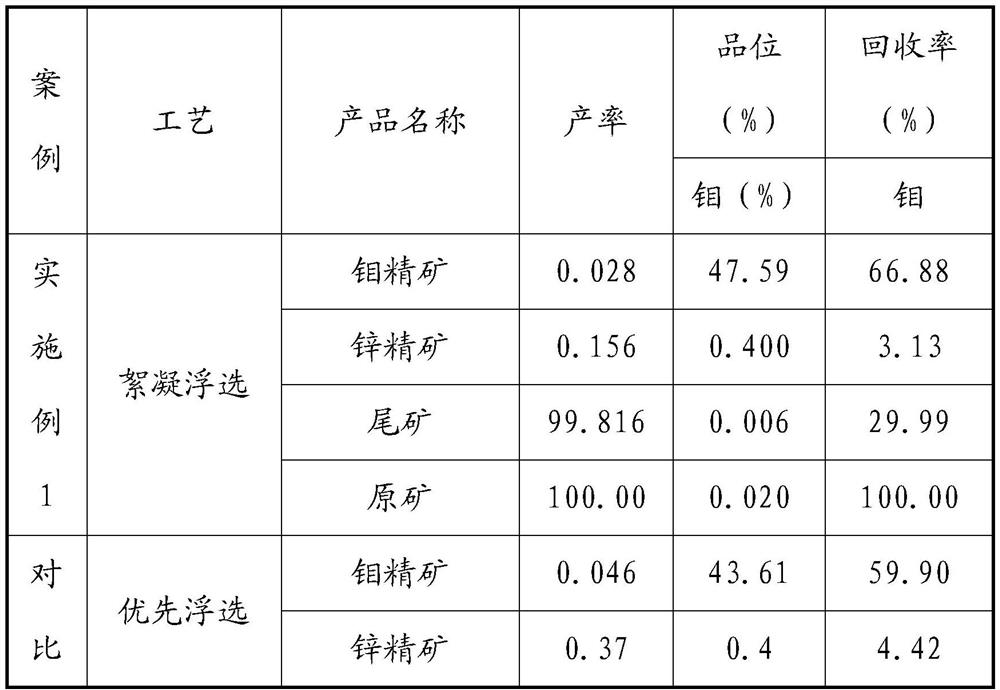

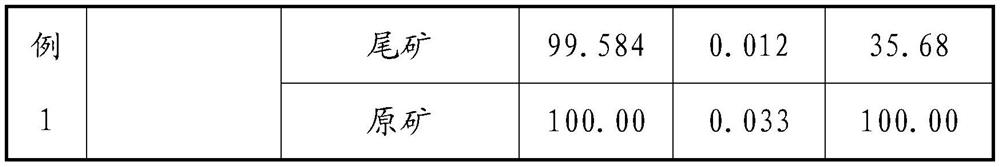

Embodiment 1

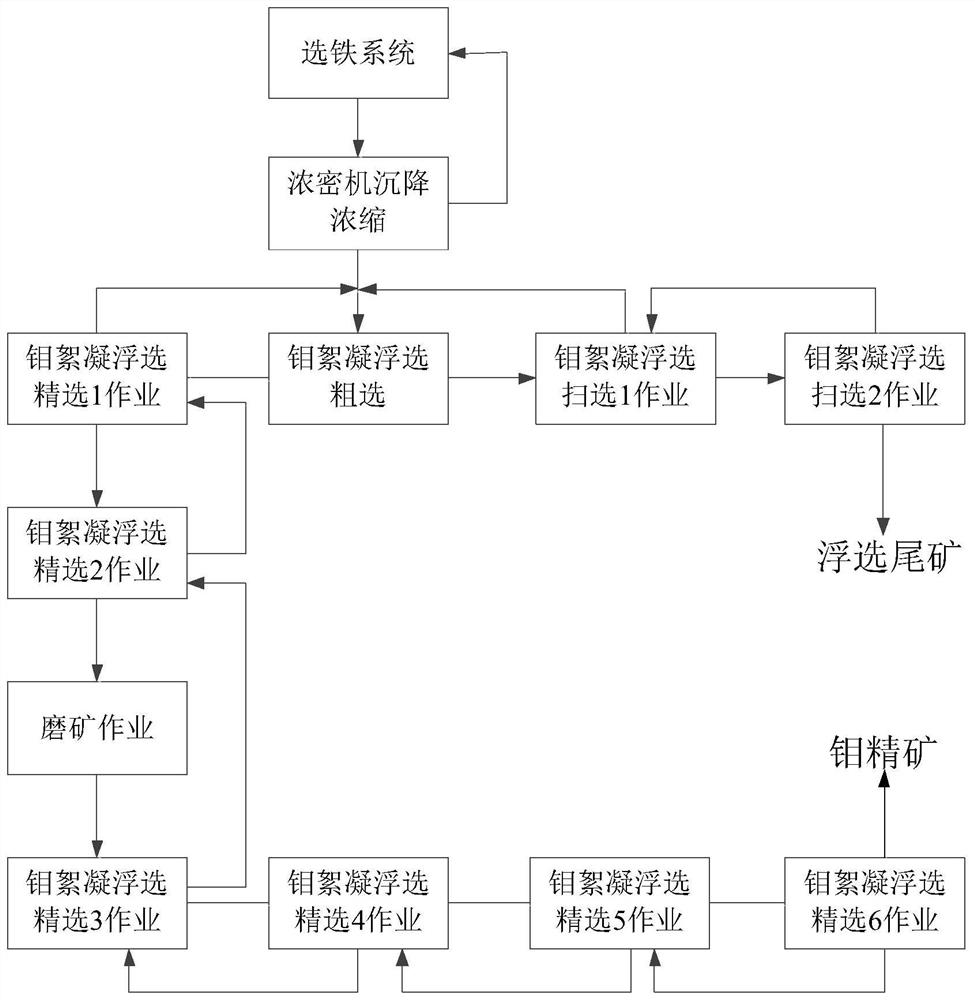

[0026] The present embodiment provides a flocculation flotation method for comprehensively recovering fine-grained molybdenum from iron tailings, and the specific process is:

[0027] S1. Settlement operation: add the iron dressing tailings slurry with a mass concentration of 20% to the thickener, add the amount of polymer acrylamide to 25g / t, and after the thickener settles, introduce the underflow into the flotation machine for flocculation and flotation roughing operation;

[0028] S2, flocculation and flotation roughing operation: add the settled underflow of the thickener to the flotation machine, add 300g / t of polyaluminum chloride, 1200g / t of water glass, and 750g / t of zinc sulfate + sodium sulfite respectively, and the combined collection 36g / t, 24g / t of kerosene and diesel oil, and 20g / t of terpineol oil, respectively, were stirred for 3 minutes, 4 minutes, 4 minutes, 3 minutes, and 2 minutes, respectively, followed by flocculation and flotation roughing, and the obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com