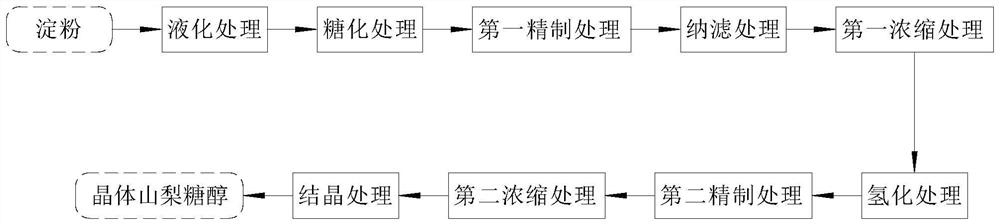

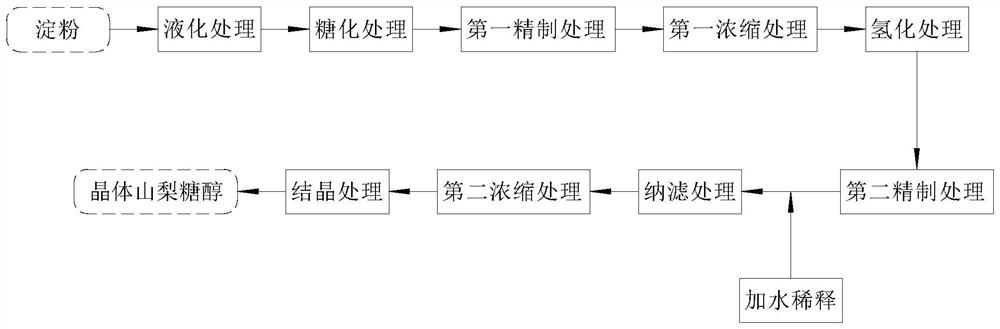

Method for preparing crystal sorbitol from liquid glucose syrup

A technology of glucose syrup and sorbitol, which is applied in the preparation of sugar derivatives, chemical instruments and methods, and the preparation of hydroxyl compounds. It can solve the problems of lack of research and achieve the effects of reducing catalyst consumption, improving hydrogenation efficiency, and reducing the amount of evaporated water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The first embodiment of the method of utilizing liquid glucose syrup to prepare crystalline sorbitol of the present invention comprises the following steps:

[0031] Step (11), the starch is subjected to liquefaction treatment, saccharification treatment, and first refining treatment to obtain liquid glucose syrup, the concentration of the liquid glucose syrup is 33.5%, wherein the glucose content is 96.2%, the maltose content is 2.1%, and the maltotriose content is 1.0% and 0.7% other larger polysaccharides.

[0032] Step (12), subjecting the liquid glucose syrup to nanofiltration treatment to obtain glucose serum and glucose concentrate respectively, the concentration of the glucose serum is 30%, wherein the glucose content is 98.7%, and the other sugar content is 1.3%. The concentration of the glucose concentrate is 35.6%, and the glucose content is 76.7%. The concentrate is collected for other use.

[0033] Step (13), carry out the first concentrated treatment of t...

Embodiment 2

[0036] The second embodiment of the method of utilizing liquid glucose syrup to prepare crystalline sorbitol of the present invention comprises the following steps:

[0037] Step (21), the starch is subjected to liquefaction treatment, saccharification treatment, and first refining treatment to obtain liquid glucose syrup, the concentration of the liquid glucose syrup is 32.0%, wherein the glucose content is 95.5%, the maltose content is 2.5%, and the maltotriose content is 1.0% and 1.0% other larger polysaccharides.

[0038] Step (22), subjecting the liquid glucose syrup to nanofiltration treatment to obtain glucose serum and glucose concentrate respectively, the concentration of the glucose serum is 29%, wherein the glucose content is 98%, and the other sugar content is 2.0%. The concentration of the glucose concentrate is 35%, the glucose content is 75%, and the concentrate is collected for other use.

[0039] Step (23), carry out the first concentrated treatment of the gl...

Embodiment 3

[0042] The third embodiment of the method of utilizing liquid glucose syrup to prepare crystalline sorbitol of the present invention comprises the following steps:

[0043] Step (31), the starch is subjected to liquefaction treatment, saccharification treatment, and first refining treatment to obtain liquid glucose syrup, the concentration of the liquid glucose syrup is 32.5%, wherein, the glucose content is 96%, the maltose content is 2.3%, and the maltotriose content is 0.8% and not more than 0.9% of other larger molecular polysaccharides.

[0044] Step (32), subjecting the liquid glucose syrup to nanofiltration treatment to obtain glucose serum and glucose concentrate respectively, the concentration of the glucose serum is 31%, wherein the glucose content is 99%, other sugar content is 1%, and the The concentration of the glucose concentrate is 37%, and the glucose content is 77%. The concentrate is collected for other use.

[0045] Step (33), carry out the first concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com