Preparation method of p-toluenesulfonyl isocyanate

A technology of toluenesulfonyl isocyanate and p-toluenesulfonamide is applied in the field of preparation of p-toluenesulfonyl isocyanate, can solve the problems of poor production safety and high equipment requirements, and achieves high recycling rate, high safety and high product yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

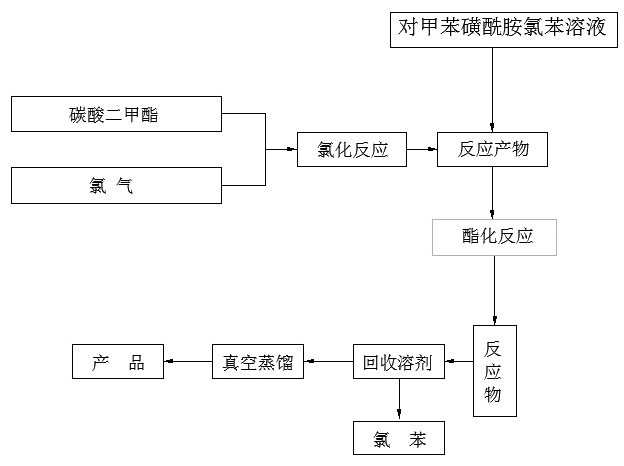

Method used

Image

Examples

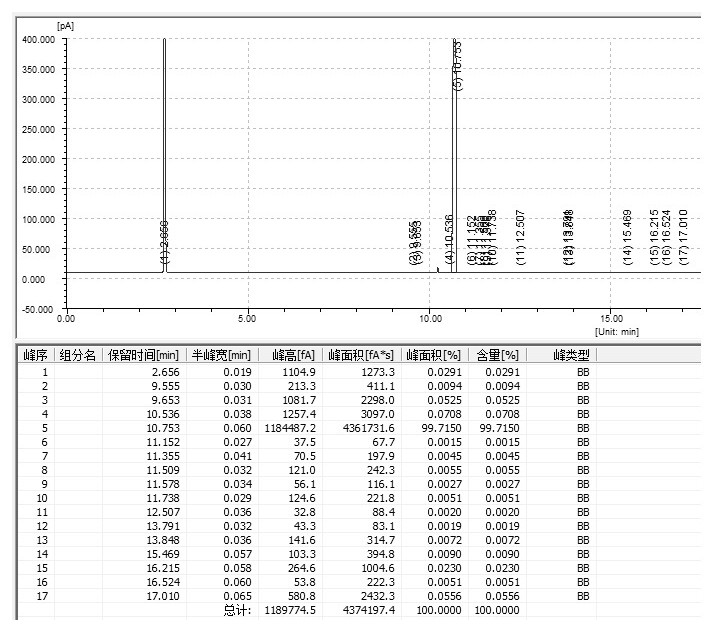

Embodiment 1

[0028] Add 47.76g of dimethyl carbonate (content 99%, 0.525mol) into a 500ml four-pin bottle, stir and pass in 228.14g of chlorine gas (content 99.9%, 3.21 mol, dimethyl carbonate: chlorine = 1:6.11), slowly pass With the reaction, the temperature gradually increased, adding a water bath, controlling the temperature to 30°C, and the chlorine passing time was about 8 hours to complete.

[0029] Stir and dissolve 86.04g p-toluenesulfonamide (content 99.5%, 0.5mol, p-toluenesulfonamide: dimethyl carbonate = 1:1.05) and 86g chlorobenzene, and add it to a constant pressure dropping funnel.

[0030] After the chlorine reaction is completed, add the p-toluenesulfonamide chlorobenzene solution into the four-necked bottle, stir and raise the temperature to above 90°C, control the temperature at 90°C and react for 4 hours, take a sample to detect the complete reaction of the raw materials, connect the condenser tube and the receiving bottle, and start recovery The solvent is chlorobenze...

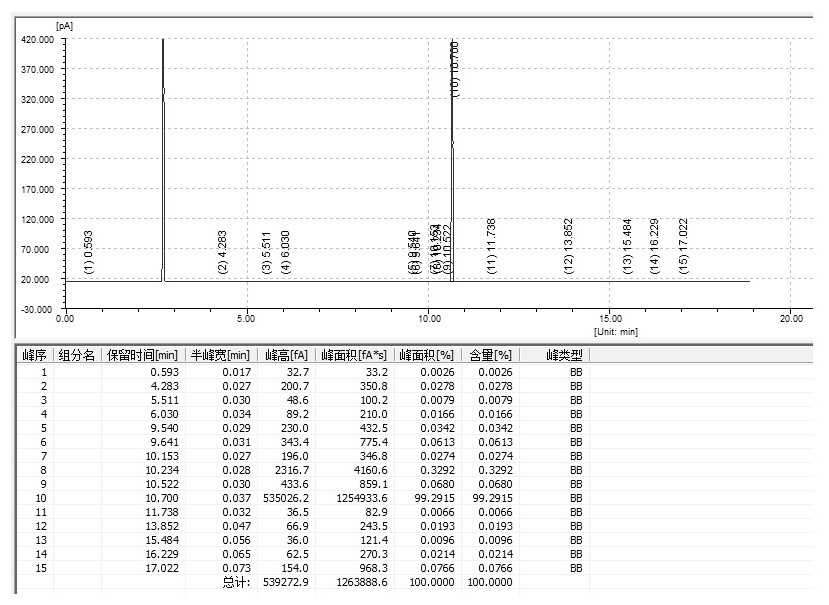

Embodiment 2

[0033] Add 45.49g of dimethyl carbonate (content 99%, 0.5mol) into a 500ml four-pin bottle, stir and pass in 234.53g of chlorine gas (content 99.9%, 3.3mol, dimethyl carbonate: chlorine = 1:6.6), slowly pass With the reaction, the temperature gradually increased, adding a water bath, controlling the temperature to 40°C, and the chlorine passing time was about 8 hours to complete.

[0034] Stir and dissolve 86.04g p-toluenesulfonamide (content 99.5%, 0.5mol, p-toluenesulfonamide: dimethyl carbonate = 1:1) and 86g chlorobenzene, and add it to a constant pressure dropping funnel.

[0035] After the chlorine reaction is completed, add the p-toluenesulfonamide chlorobenzene solution into the four-necked bottle, stir and raise the temperature to above 90°C, control the temperature at 100°C for 4 hours, take a sample to check that the raw material has reacted completely, connect the condenser tube and the receiving bottle, and start recovery The solvent is chlorobenzene, the vacuum d...

Embodiment 3

[0038] Add 50.04g of dimethyl carbonate (content 99%, 0.55mol) into a 500ml four-pin bottle, stir and pass in 232.53g of chlorine gas (content 99.9%, 3.3mol, dimethyl carbonate: chlorine = 1:6), slowly pass With the reaction, the temperature is gradually increased, add a water bath, control the temperature at 50°C, and complete the chlorine passage in about 8 hours.

[0039] Stir and dissolve 86.04g p-toluenesulfonamide (content 99.5%, 0.5mol, p-toluenesulfonamide: dimethyl carbonate = 1:1.1) and 86g chlorobenzene, and add to the constant pressure dropping funnel.

[0040] After the chlorine reaction is completed, add the p-toluenesulfonamide chlorobenzene solution into the four-necked bottle, stir and heat up to above 90°C, control the temperature at 105°C for 4 hours, take a sample to check that the raw material has reacted completely, connect the condenser tube and the receiving bottle, and start recovery The solvent is chlorobenzene, the vacuum degree is controlled at -0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com