Method for extracting xyloglucan from tamarind seeds

A technology for xyloglucan and tamarind polysaccharide, which is applied in the field of plant polysaccharide extraction, can solve the problems of restricting the application of tamarind xyloglucan, poor solubility and low purity, and achieves the effects of high purity, promotion of application and reduction of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

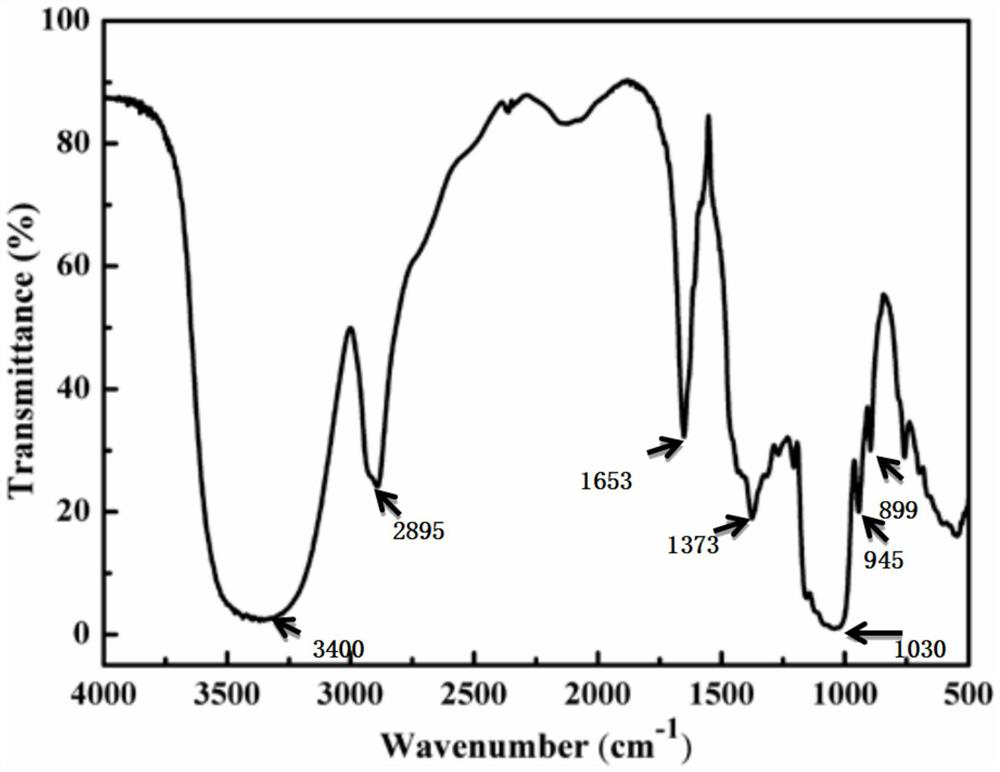

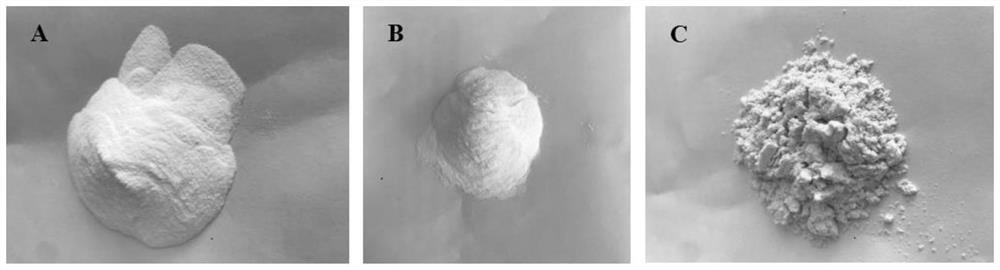

Image

Examples

Embodiment 1

[0029] A method for extracting xyloglucan in tamarind seeds, the steps are as follows:

[0030] (1) Tamarind seeds are pretreated to obtain tamarind polysaccharide coarse powder, and tamarind polysaccharide coarse powder is prepared into a 1% solution with water and dissolved at 80° C. for 6 hours;

[0031] (2) Centrifuge at 9000rpm for 15min, and get the supernatant, which is the tamarind polysaccharide solution;

[0032] (3) Add 0.5% lactic acid to the tamarind polysaccharide solution, adjust the pH to 3.5, then let it settle for 3 hours at room temperature, and then centrifuge to obtain the supernatant I;

[0033] (4) Add 0.1% sodium hydroxide to the supernatant I, adjust the pH to 11, let it settle for 2 hours, and centrifuge to obtain the supernatant II;

[0034] (5) Add 2% activated carbon to the supernatant II and stir for 4 hours for adsorption, and obtain the supernatant III after centrifugation;

[0035] (6) Put the supernatant III into a 50kDa dialysis bag in a st...

Embodiment 2

[0039] A method for extracting xyloglucan in tamarind seeds, the steps are as follows:

[0040] (1) Tamarind seeds are pretreated to obtain tamarind polysaccharide coarse powder, and tamarind polysaccharide coarse powder is prepared into a 3% solution with water, and dissolved at 90° C. for 4 hours;

[0041] (2) Centrifuge at 9000rpm for 15min, and get the supernatant, which is the tamarind polysaccharide solution;

[0042] (3) Adding 1% acetic acid to the tamarind polysaccharide solution, adjusting the pH to 4.2, then standing still at room temperature for 6 hours, and then centrifuging to obtain the supernatant I;

[0043] (4) Add 1% potassium hydroxide to the supernatant I to adjust the pH to 12.1, then let it settle for 4 hours at room temperature, and then centrifuge to obtain the supernatant II;

[0044] (5) Add 2% activated carbon to the supernatant II and stir for 4 hours for adsorption, and obtain the supernatant III after centrifugation;

[0045] (6) Put the supern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com