Preparation method of high-moisture-permeability waterproof coating primer resin for spinning

A moisture-permeable waterproof and coating technology, applied in textiles and papermaking, liquid-repellent fibers, fiber treatment, etc., can solve problems such as poor adhesion fastness, poor washing resistance, and insufficient air permeability , to achieve high moisture permeability, good cold resistance, and good bonding fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment discloses a preparation method of a high moisture-permeable waterproof coating primer resin for textiles, including a reaction kettle. The preparation method includes: putting 85 parts of polyester polyol and 185 parts of polyethylene glycol into the reaction kettle, 30 parts of polyoxypropylene glycol, 6 parts of ethylene glycol, stir and mix evenly. Then add 20 parts of toluene diisocyanate, and control the reaction temperature between 70-80°C for 2-3 hours; maintain the reaction temperature and put in 205 parts of toluene, 50 parts of dimethylformamide, and 8.6 parts of diphenylmethane diisocyanate in batches. Isocyanate: when the viscosity of the resin reaches 100000-150000CPS and the solid content reaches the benchmark of 49-51%, add 0.8 part of terminator methanol and 80 parts of dimethylformamide to terminate the reaction. The cooling package is the finished product.

[0036]

[0037]

[0038] This embodiment is compared with the existing w...

Embodiment 2

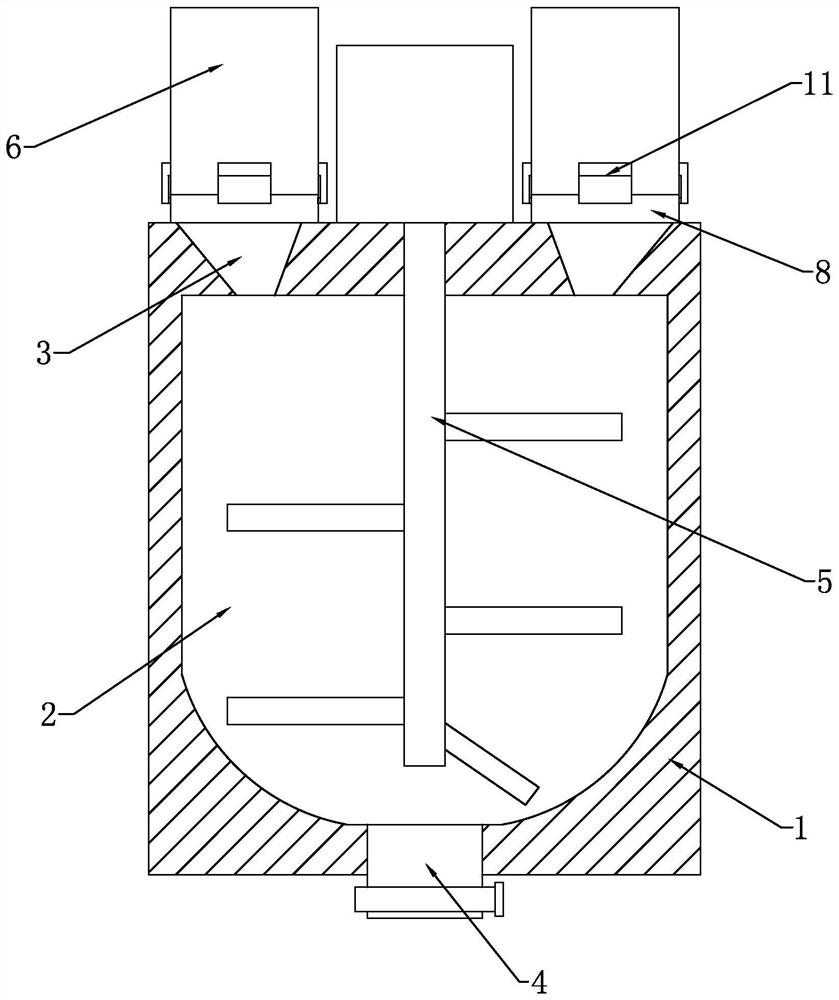

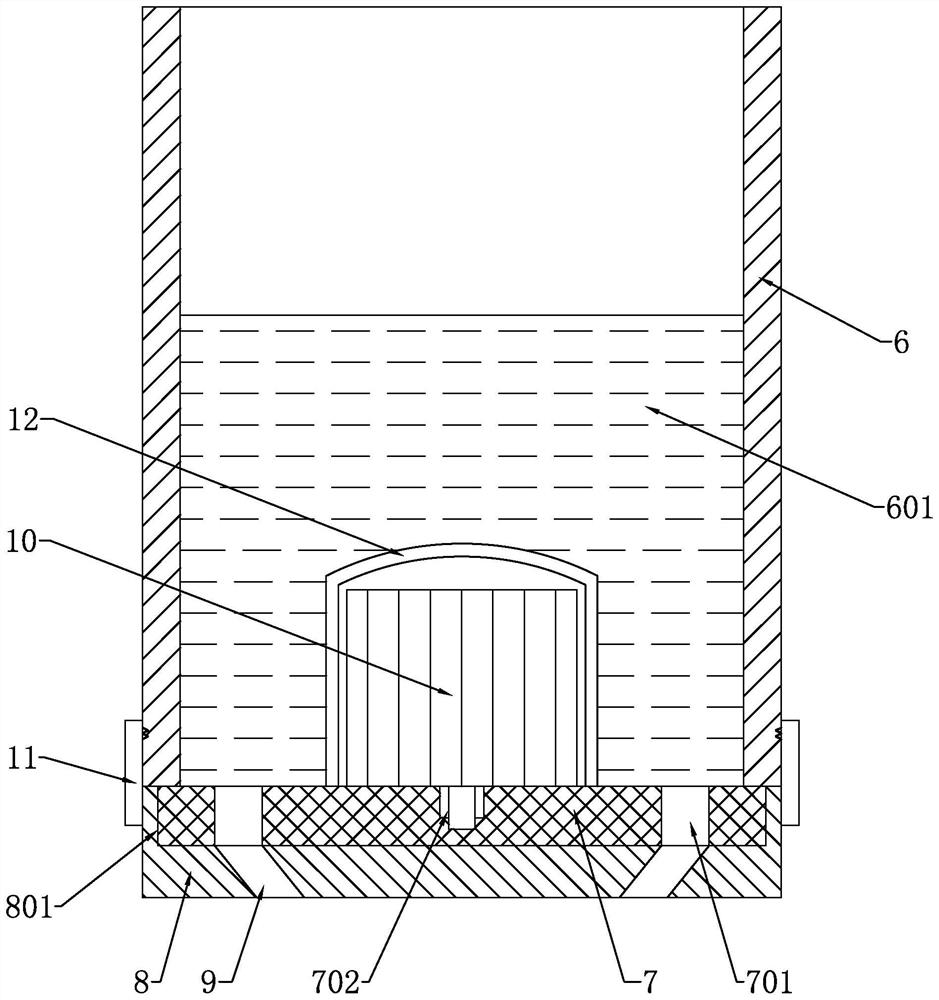

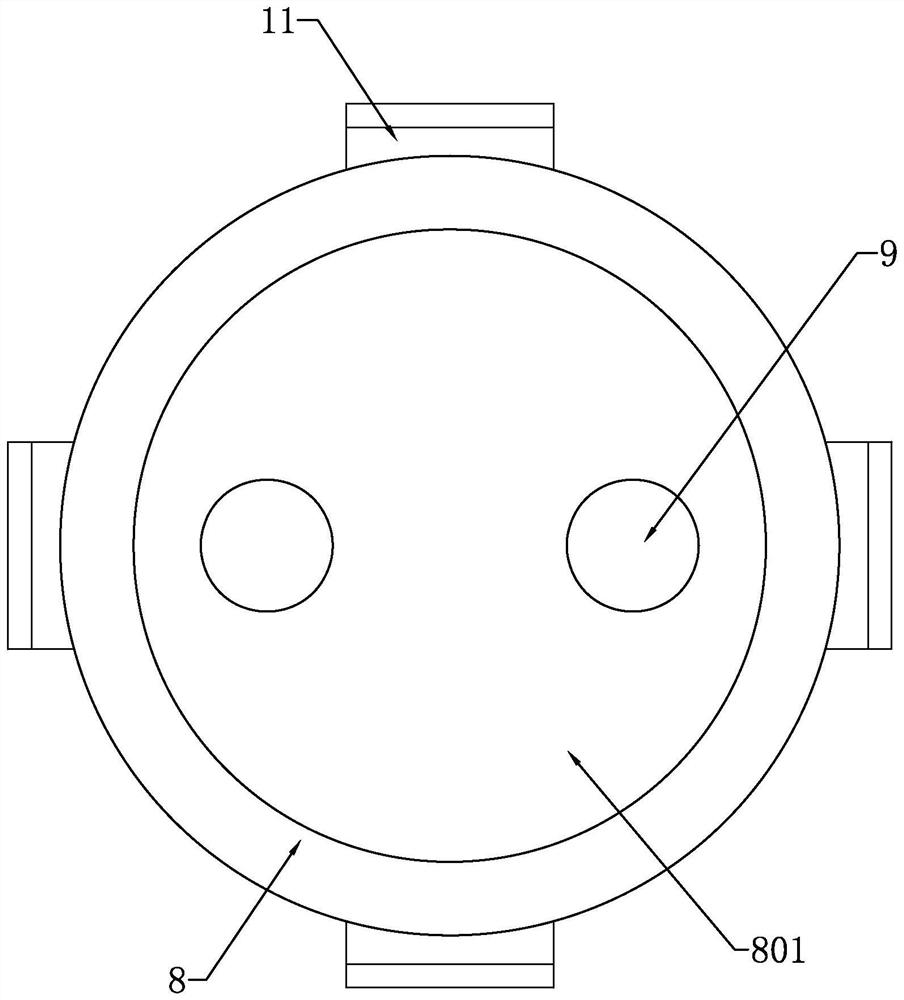

[0046] This embodiment discloses a reaction kettle suitable for the preparation of the resin in the previous embodiment. The reaction kettle includes: a kettle body 1, which has a mixing chamber 2 for containing raw materials, and is provided with an inlet connected to the mixing chamber 2. Port 3 and export port 4; Stirring assembly 5, which is located in the mixing chamber 2 for stirring the raw materials; several raw material import barrels 6, which are distributed on the top of the kettle body 1, and each raw material import barrel 6 is equipped with The storage room, the bottom of the raw material import barrel 6 has a raw material outlet 9 connected to the storage room, and the raw material outlet 9 communicates with the import port 3; the baffle 7 is located between the storage room and the raw material outlet 9, when the baffle 7 is located at the first The raw material outlet 9 is closed when the baffle 7 is in the second position, and the raw material outlet 9 is open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com