Method for improving ionization rate in vapor deposition process by using vacuum ultraviolet light

A vacuum ultraviolet light and vapor deposition technology, applied in the field of vapor deposition, can solve the problems of high cost, increased design difficulty and design cost, poor versatility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

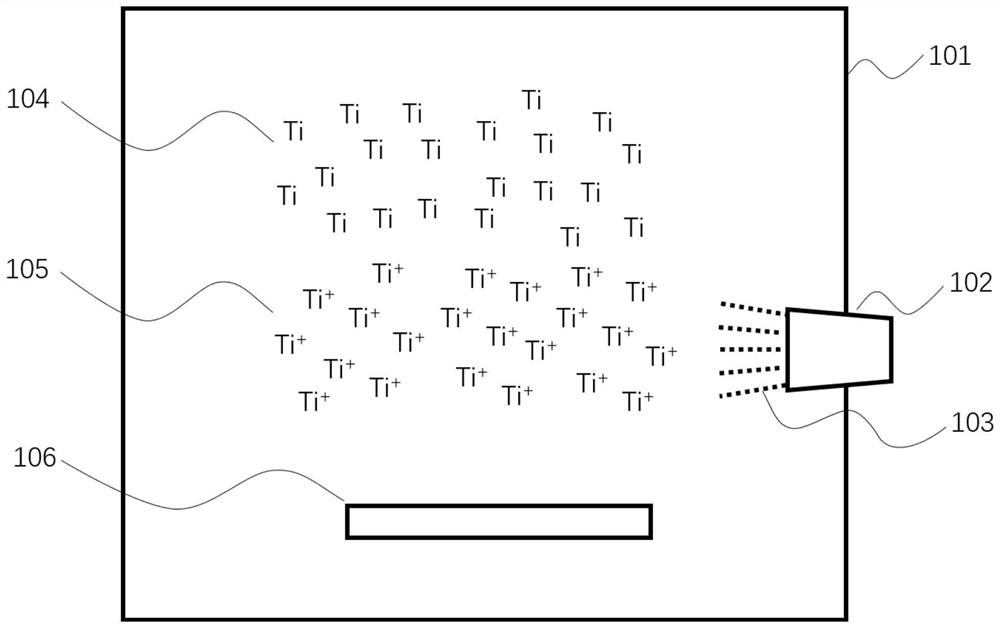

[0031] Such as figure 1 As shown, a method of using vacuum ultraviolet light to realize the ionization rate in vapor deposition according to the present invention, it is the gas phase atomic distribution of Ti in the vapor deposition chamber comprising a set of vacuum ultraviolet ionization light source, after vacuum ultraviolet ionization Schematic diagram of the distribution of Ti+ gas phase ions. Specifically including 101-vacuum vapor deposition chamber; 102-deuterium lamp vacuum ultraviolet light source with a peak wavelength of 165nm; 103-vacuum ultraviolet light beam with a peak wavelength of 165nm; 104-Ti gas phase atoms; 105-Ti+ gas phase ions; 106-workpiece to be coated .

[0032] Specifically, in the vacuum vapor deposition chamber 101, a deuterium lamp vacuum ultraviolet light source 102 with a peak wavelength of 165nm is added; after being powered on, it can emit a vacuum ultraviolet light beam 103 with a peak wavelength of 165nm. The photon energy of the ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com