Coating with super bonding strength and preparation method thereof

A super-combination and coating technology, applied in coatings, metal material coating processes, manufacturing tools, etc., can solve the problem of limiting laser directed energy deposition coatings, increasing the complexity of the manufacturing process, and prone to radial crack delamination To achieve the effect of improving work stability and service life, good metallurgical bonding quality, and reducing crack sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

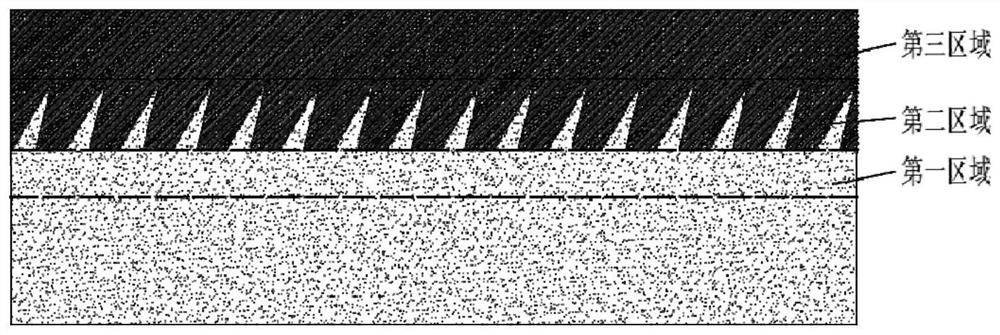

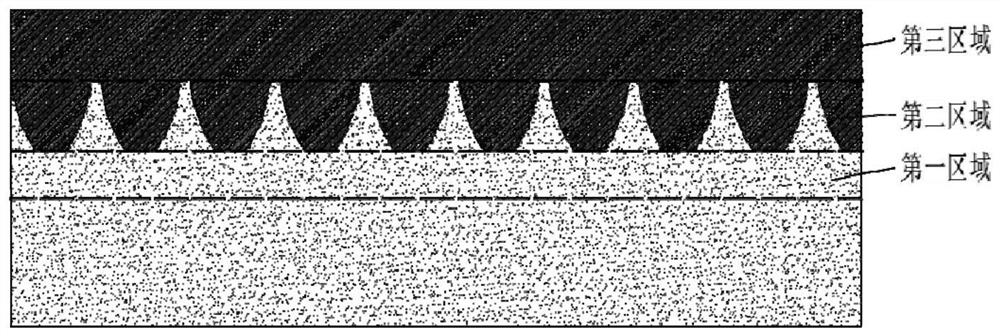

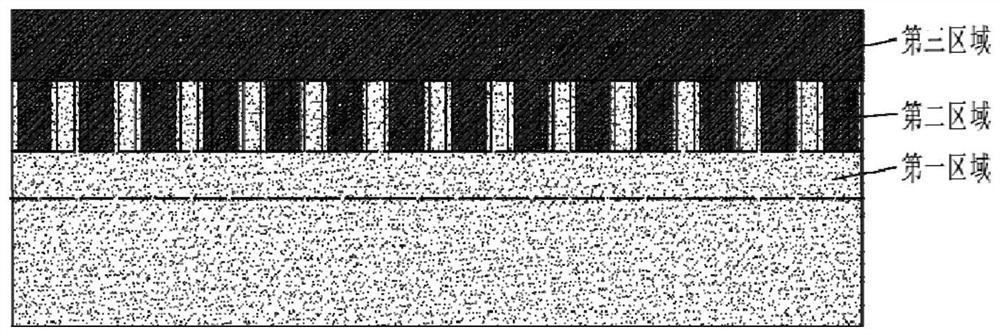

[0044] As shown in the figure, the present invention provides a method for preparing a coating with super bonding strength, which is a method for improving the bonding strength between the coating and the substrate, and the method includes the following steps:

[0045] - provide a metal substrate;

[0046] —Designing the contour features of the bionic microstructure, the bionic microstructure includes: the wedge-shaped structure imitating cocklebur, the concave arc structure imitating sunflower, the honeycomb honeycomb structure imitating honeycomb, or the biomimetic microstructure imitating inverted pyramid structure;

[0047] —According to the material of the metal matrix provided, select the laser deposition powder material superior to the surface performance of the matrix, the laser deposition powder material includes: iron-based alloy, nickel-based alloy or heterogeneous element reinforced nickel-based composite powder material, optimize the Deposition powder laser deposi...

Embodiment 1

[0066] A manufacturing method for improving the bonding strength between a coating and a substrate. A coating with good metallurgical bonding quality with the substrate and excellent mechanical properties is prepared on the surface of a shaft, specifically comprising the following steps:

[0067] a. Provide cylindrical substrate (45# steel);

[0068] b. The shaft is clamped on the workbench, and the laser processing and manufacturing method is used to process the bionic microstructure on the surface of the shaft with pulsed laser;

[0069] Specifically: the bionic microstructure of the shaft surface needs to be obtained through experiments, the stepping motor controls the rotational movement of the shaft, and adjusts the relative position between the shaft surface to be processed and the focal point of the laser spot according to the optimal working distance of the pulse laser during the experiment, Control the movement of the stepper motor and the laser according to the desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com