Sound insulation, heat preservation and heat insulation box body and walk-in type high and low temperature silencing box

A technology of thermal insulation and thermal insulation board, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, instruments, and analytical materials, etc. It can solve the problem of inability to meet the low noise requirements of acoustic tests, the inability to simulate the sound field environment, and the decline in heat insulation performance To achieve excellent sound insulation performance and thermal insulation performance, improve sound insulation performance, and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

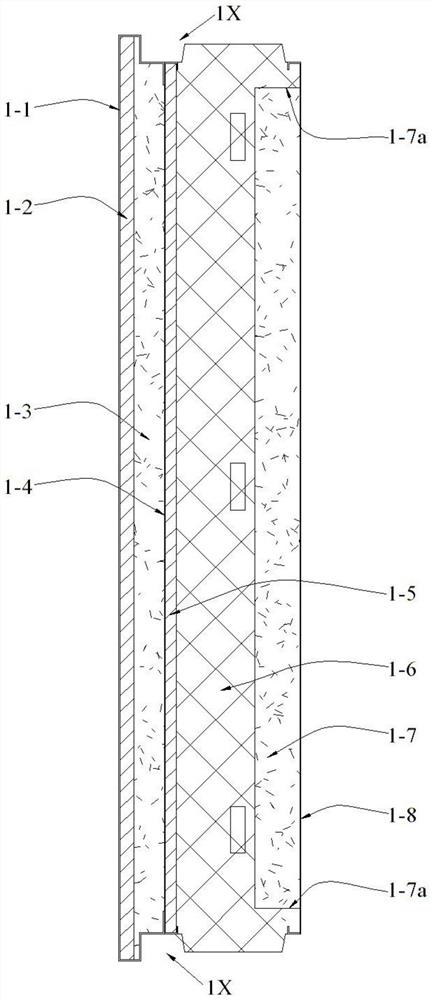

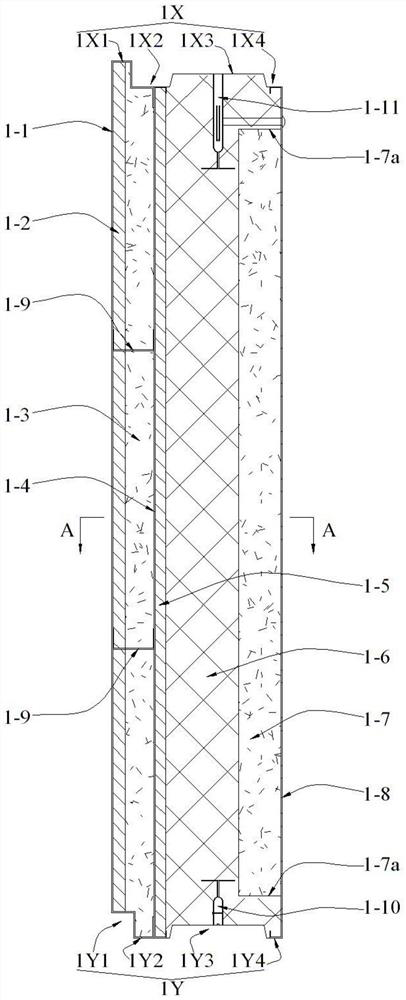

[0045] Such as figure 1 and figure 2 As shown, the present invention discloses a sound insulation heat insulation box 1, which is composed of sound insulation heat insulation boards, and the sound insulation heat insulation boards are composed of outer wall steel plates 1-1, damping Sound insulation board 1-2, sound absorption material 1-3, middle steel plate 1-4, fiber cement board 1-5, foamed polyurethane material 1-6, sound absorption and heat insulation material 1-7 and inner wall steel plate 1-8 . Wherein, the sound-absorbing and heat-insulating materials 1-7 may be existing materials such as rock wool, ceramic wool, etc., which have both sound-absorbing and heat-insulating properties.

[0046] Therefore, the low-frequency sound insulation performance of the sound insulation and heat insulation board can be enhanced by the damping sound insulation board 1-2, and the middle steel plate 1-4 and the inner wall steel plate 1-8 can be isolated by the sound absorption and he...

Embodiment 2

[0052] Such as Figure 1 to Figure 3 As shown, on the basis of the first embodiment above, the second embodiment also adopts the following preferred structure:

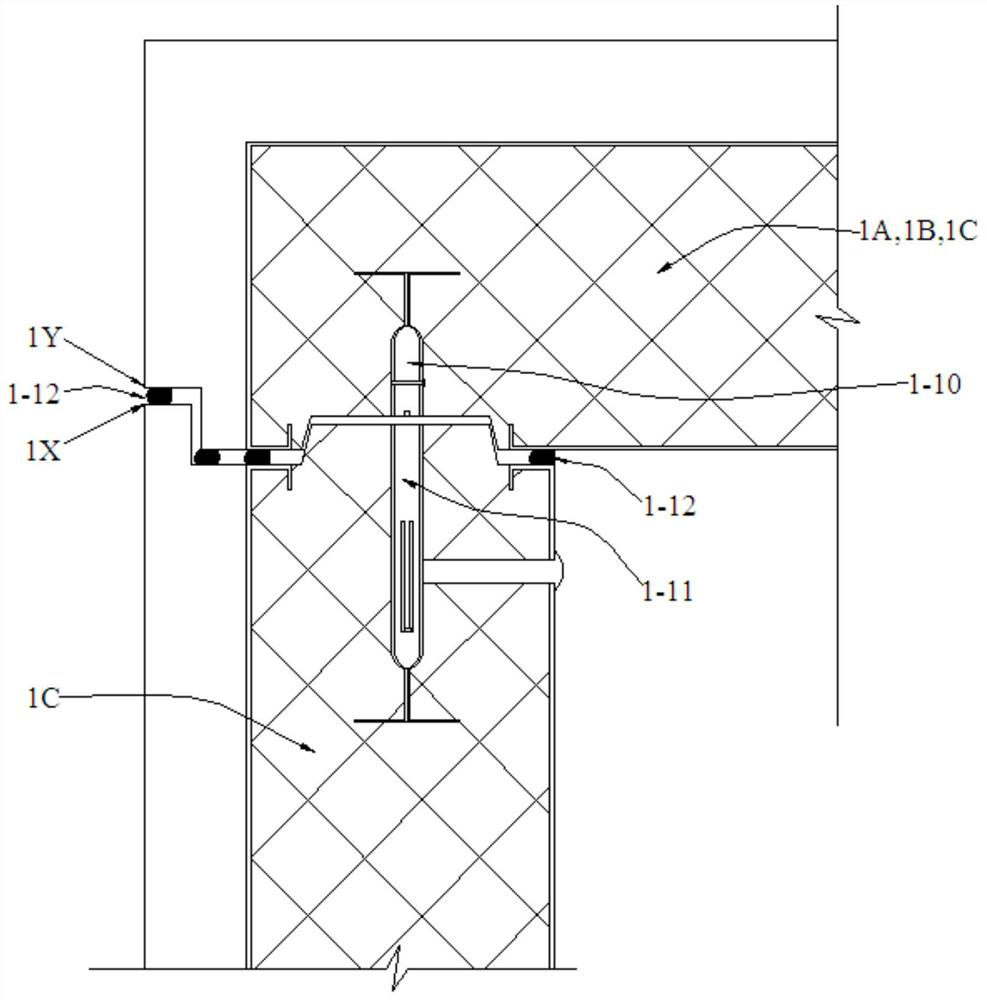

[0053] The sound insulation and heat insulation box 1 is assembled from a plurality of sound insulation and heat insulation panels, wherein the two adjacent sound insulation and heat insulation panels adopt the following assembly structure: the two adjacent sound insulation and heat insulation panels The heat insulation boards are formed with a mating male splicing interface 1X and a female splicing interface 1Y on their respective splicing surfaces. The male splicing interface 1X is composed of rectangular bumps 1X1, transition grooves 1X2, and trapezoidal bumps 1X3 that are sequentially connected from outside to inside. , transition notch 1X4, the female splicing interface 1Y is composed of a rectangular groove 1Y1, a transition bump 1Y2, a trapezoidal groove 1Y3, and a transition bump 1Y4 that are sequentially conn...

Embodiment 3

[0060] Such as Figure 5 to Figure 7As shown, Embodiment 3 of the present invention discloses a walk-in high and low temperature anechoic box, including: the sound insulation and heat insulation box 1 described in Embodiment 1 or Embodiment 2, and the sound insulation and heat insulation box 1 The inner wall of the inner cavity is equipped with a sound absorbing body 4; and, the outside of the sound insulation and heat insulation box 1 is provided with a motor 5 and a refrigeration system 6, and the inner cavity of the sound insulation and heat insulation box 1 is divided into successively Connected anechoic test room 1u, ventilation muffler room 1v and working condition room 1w, the motor shaft of the motor 5 is connected with the fan 8 located in the working condition room 1w through the rotating shaft 7, and the ventilation muffler room 1v is installed usefully The ventilation muffler for eliminating wind noise, the evaporator 6-1 and the heater 6-2 of the refrigeration sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com