A kind of functional diaphragm and its preparation method and application

A membrane and functional technology, applied in the field of functional membrane and its preparation, to achieve the effects of improving safety and stability, easy to scale, and prolonging the nucleation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The present invention also provides the preparation method of the functional diaphragm described in the above technical solution, comprising the following steps:

[0070] Mixing the anionic covalent organic framework, polyvinylidene fluoride (PVDF) and N-methylpyrrolidone (NMP) to obtain a slurry;

[0071] The slurry is coated on the surface of the separator to obtain the functional separator.

[0072] In the present invention, the anionic covalent organic framework, polyvinylidene fluoride and N-methylpyrrolidone are mixed to obtain slurry.

[0073] In the present invention, the mixing is preferably performed under the condition of magnetic stirring, the time of the magnetic stirring is preferably 6-12 h, and the rotation speed is preferably 200-300 rpm.

[0074] After the slurry is obtained, the present invention coats the slurry on the surface of the separator to obtain the functional separator.

[0075] In the present invention, the coating is preferably performed...

Embodiment 1

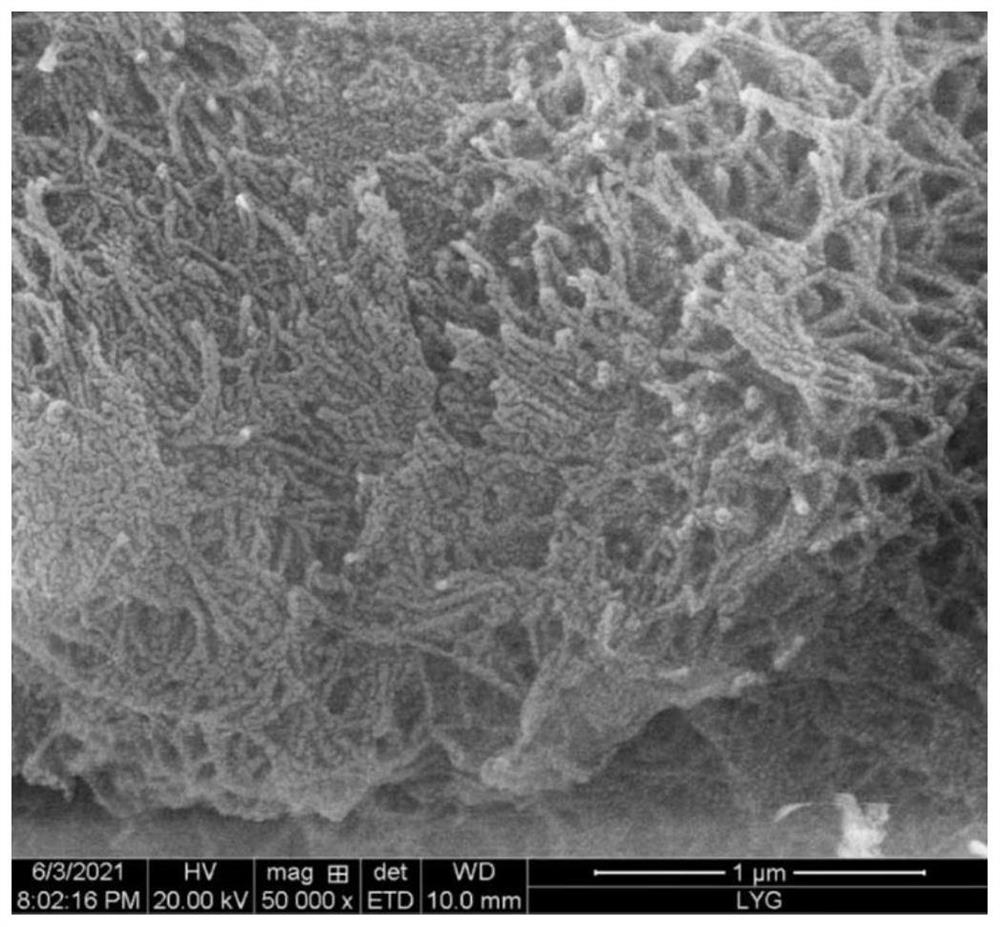

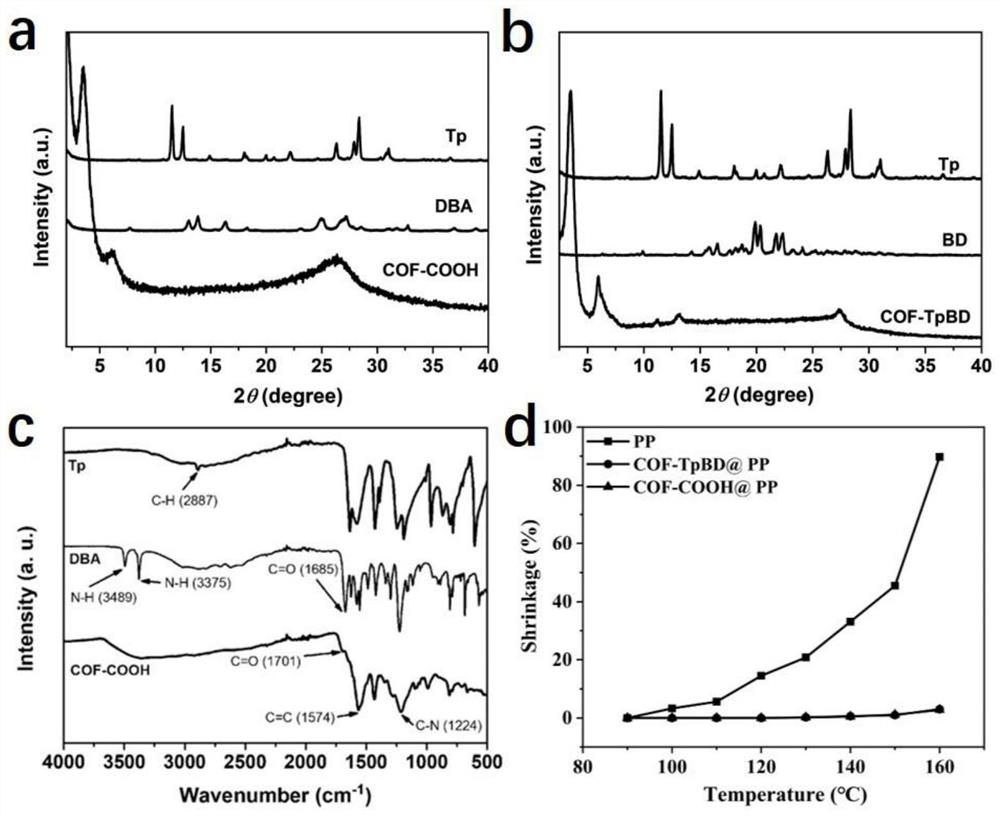

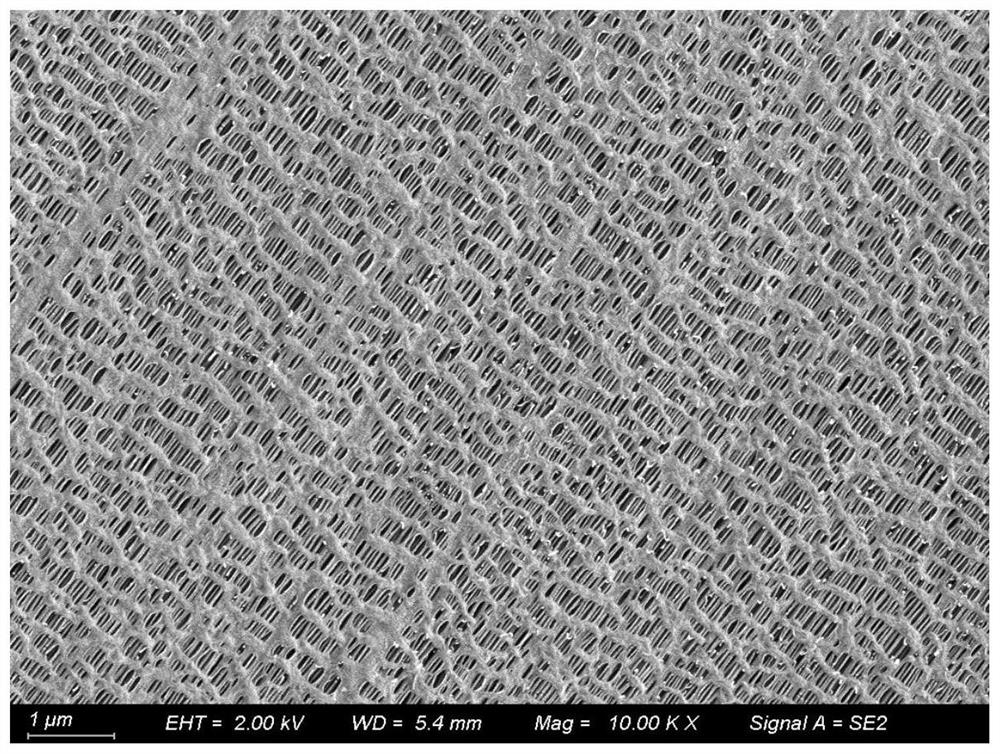

[0081] An anionic covalent organic framework modified functional separator (COF-COOH@PP), which specifically includes the following steps:

[0082] Step 1: The monomers 2,4,6-trihydroxy-1,3,5-benzenetricarbaldehyde (63.0 mg) and 4,4'-diamino-1,1'-biphenyl-3,3'- Dicarboxylic acid (122.5mg) was mixed into a rigid ampoule, and 1,4-dioxane (1mL) and 1,3,5-trimethylbenzene (3mL) were added to the ampoule in a volume ratio of 1:3. ), ultrasonicating the ampoule containing the mixed solution for 10 minutes to make the above solution evenly mixed; after adding 0.6 mL of 6M acetic acid aqueous solution dropwise to the solution, the ampoule containing the mixed solution was placed in liquid nitrogen for freezing. To remove excess air and moisture in the ampoules that could affect the reaction, the ampoules were vacuum-thawed-frozen three times. After the impurities are exhausted, use the oil pump to vacuum again, and vacuum seal under the condition that the inside of the ampoule is vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com