Method for optimizing crystallization of potassium chloride based on online monitoring system

A monitoring system and potassium chloride technology, applied in chemical instruments and methods, solution crystallization, crystallization separation, etc., can solve problems such as inability to achieve optimal crystallization effect, secondary nucleation, spontaneous nucleation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

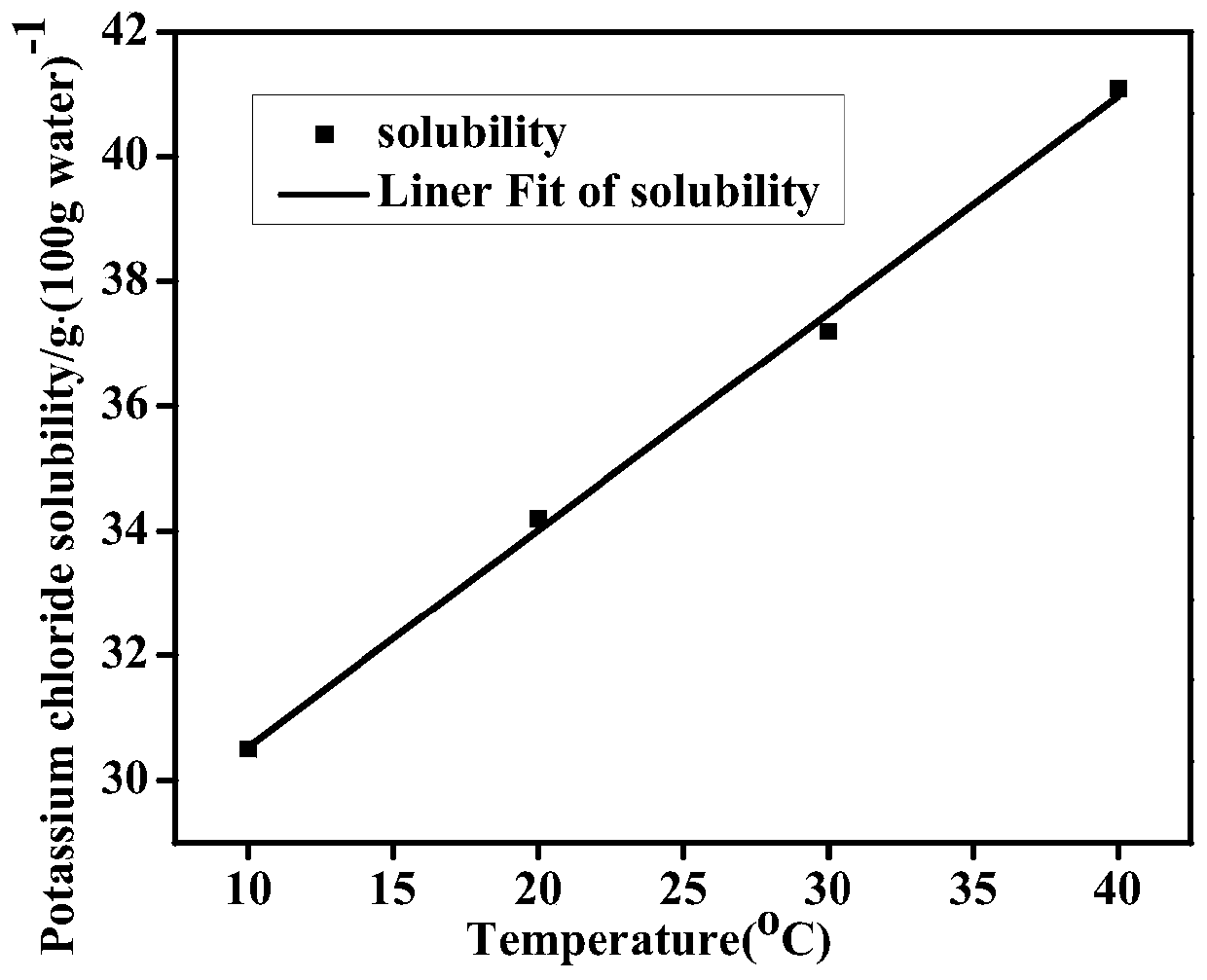

[0050] The present embodiment provides determination of solubility:

[0051] Using the static method, from high temperature to low temperature, to measure the solubility of potassium chloride at different temperatures, add 100mL of high-purity water to the jacketed crystallizer, open the program-controlled constant temperature bath, and set the temperature to 10°C, 20 ℃, 30 ℃, 40 ℃, a total of four groups, keep warm for 30 minutes respectively, add 50g of potassium chloride, turn on the electromagnetic stirrer and stir at constant temperature for 1 hour, so that the system can fully reach the state of solid-liquid two-phase equilibrium, turn off the magnetic stirring, and let it stand 1h, and read the temperature T, the mass of the pipette with the tip of the pipette is m 1 Pipette gun to pipette 10mL supernatant, weigh the total mass of the pipette and the solution m 11 , move the solution into the crucible, then the total mass is m 2 , and rinse the straw with pure solvent...

Embodiment 2

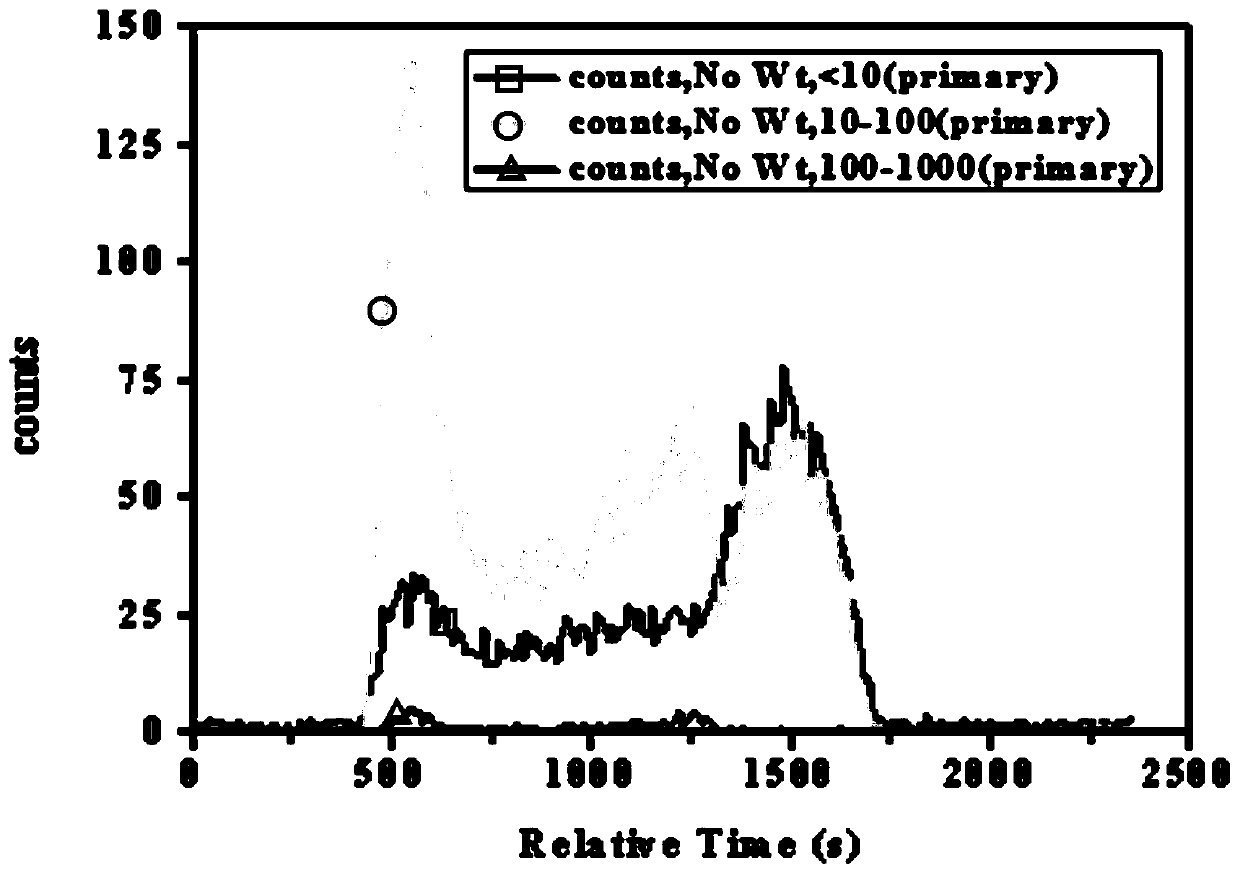

[0054] In this embodiment, without adding seed crystals, the metastable zone of potassium chloride is determined.

[0055] Take potassium chloride and water into the crystallizer according to the mass ratio of 1:5, turn on the stirrer, FBRM, PVM online monitoring system, and insert the temperature probe, heat up to 55°C to completely dissolve potassium chloride in the crystallizer, and then Measure the supersolubility data at a cooling rate of 5-15°C / h and a rotating speed of 200-400r / min. When tiny crystals appear, the temperature will change suddenly. Write down the temperature T when the sudden change occurs, and then the prepared potassium chloride solution will be The mass ratio is the supersolubility at this temperature. (there are 6 groups of tests in this embodiment, with stirring rate and cooling rate as variables, respectively: the stirring speed is 300r / min, and the cooling rate is 5°C / h; the stirring speed is 300r / min, 10°C / h; the stirring speed 300r / min, 15°C / h; ...

Embodiment 3

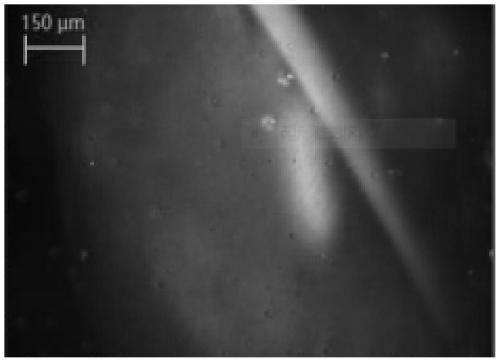

[0061] In this embodiment, crystal seeds are added to measure the metastable zone of potassium chloride.

[0062] Under the condition of a rotating speed of 300r / min, the temperature of 100g of potassium chloride solution with a mass fraction of 20% is raised to 70-90°C and then lowered to its saturation temperature T 1 After 30 minutes of heat preservation, potassium chloride seed crystals were added (two sets of data, when the seed crystal masses were 2g and 6g respectively), and the FBRM and PVM online monitoring systems were turned on at the same time, and the temperature probe was inserted, and the temperature was lowered at a rate of 5°C / h until the temperature suddenly changed. , FBRM, and PVM systems detect that the number of crystals increases, and record the corresponding temperature at this time as T 2 , the metastable zone data of the potassium chloride solution of this concentration can be obtained under the conditions of stirring rate, cooling rate and seed cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com