Vector soliton fiber laser, control method and application thereof

A fiber laser and fiber grating technology, applied in the directions of lasers, phonon exciters, laser parts, etc., can solve the problems of no correlation between vector solitons and cylindrical vector speed of light, complex structure, etc. Effects with high damage threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

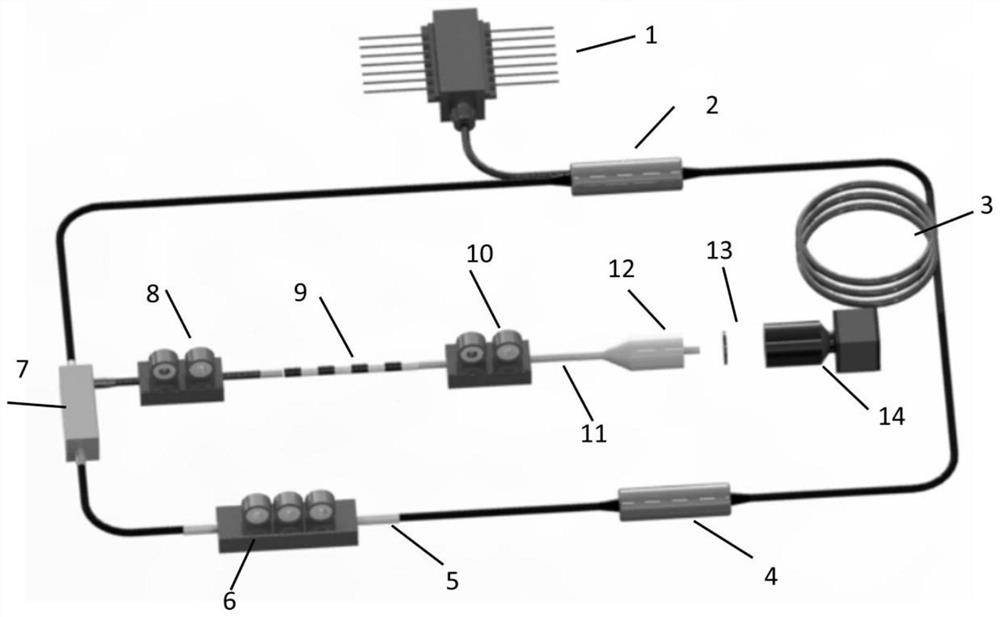

[0044] The invention provides a control method of a vector soliton fiber laser, specifically comprising:

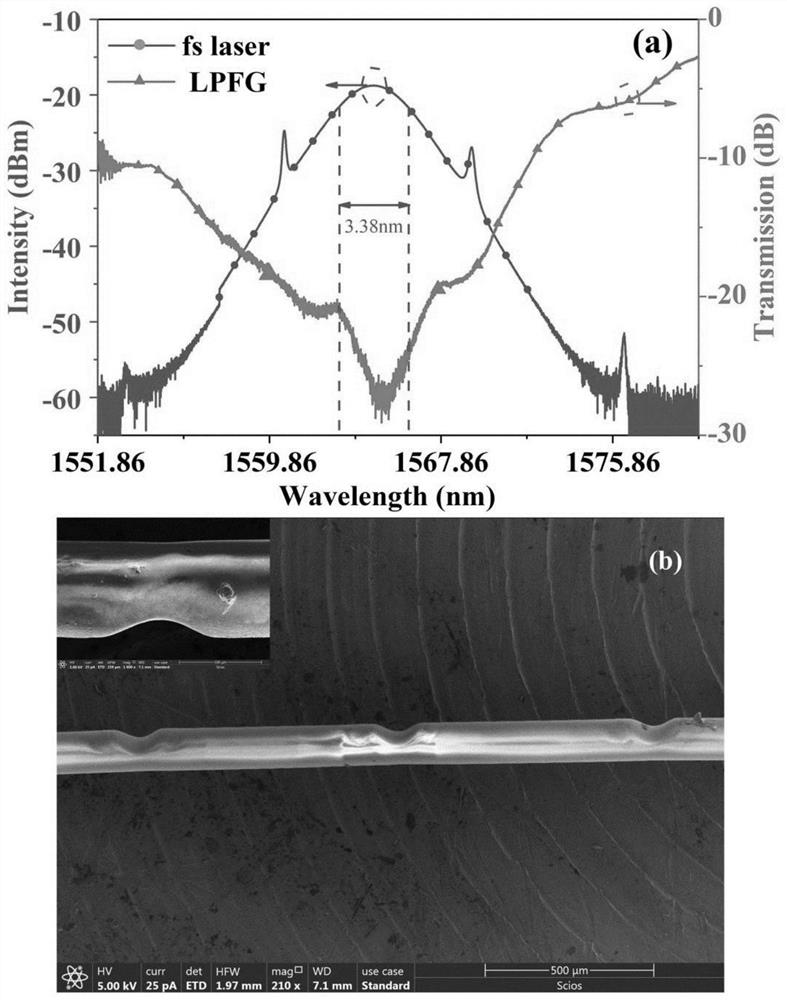

[0045] by CO 2 The laser etches the long-period fiber grating on the graded two-mode fiber, which causes an asymmetric refractive index change in the fiber, which makes the refractive index distribution of the fiber waveguide change unevenly, and the grating is written on the fiber by an external laser. The mutual orthogonality between the random destruction modes, the mode coupling of energy occurs, and the transformation from the fundamental mode light to the higher-order mode is realized;

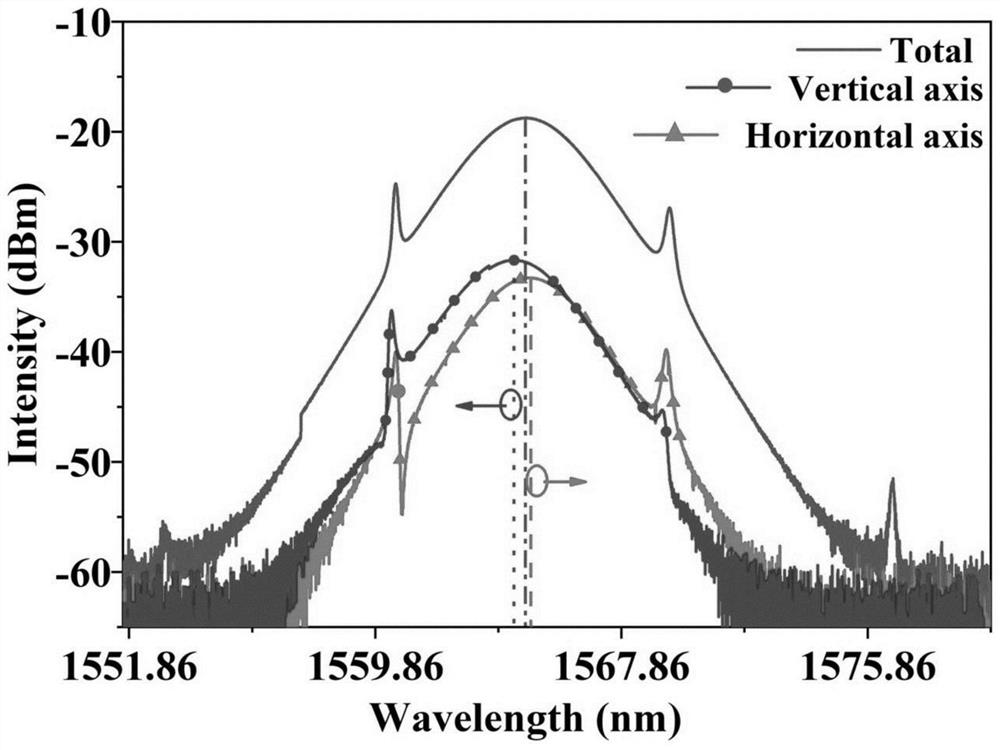

[0046] On the premise of not changing the mode-locked state in the cavity, by adjusting the polarization controller before and after the long-period fiber, twisting the polarization controller in the cavity changes the output polarization state distribution in the cavity, and finally obtains a cylindrical vector beam.

[0047] Among them, in the energy generation mode coupling, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com