Renewable nano-porous adsorption material for removing carbon dioxide and preparation method of renewable nano-porous adsorption material

An adsorption material and nanoporous technology, which is applied in the field of renewable nanoporous adsorption materials and preparation, can solve problems affecting carbon dioxide removal capacity, short service life, and low amine-based loading rate, and achieve excellent carbon dioxide adsorption and renewable performance. The effect of improving the service life and preventing the loss of amine groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 400g molecular weight 1800 is polyethyleneimine dissolved in 3kg distilled water and forms amine solution (mass fraction is 13.3%), adds 500g fumed silica nanoporous carrier to amine solution, makes fumed silica nanoporous carrier slowly settle into the amine solution, and mix well after settling to form a homogeneous mixture;

[0034] Add 75g of polyethylene glycol with a molecular weight of 4000 to the mixture, stir at room temperature, make polyethyleneimine, fumed silica nanoporous carrier and polyethylene glycol undergo a crosslinking reaction for more than 5min, then add 35g of ethylenediamine Tetrasodium tetraacetate, stirred until a gel-like product is formed;

[0035]The product was dried at room temperature for 48 hours, shaped into granules, and then dried in an oven at 100°C for 8 hours to obtain a renewable nanoporous adsorption material for removing carbon dioxide (referred to as CO2 for short). 2 -SORBENT-1).

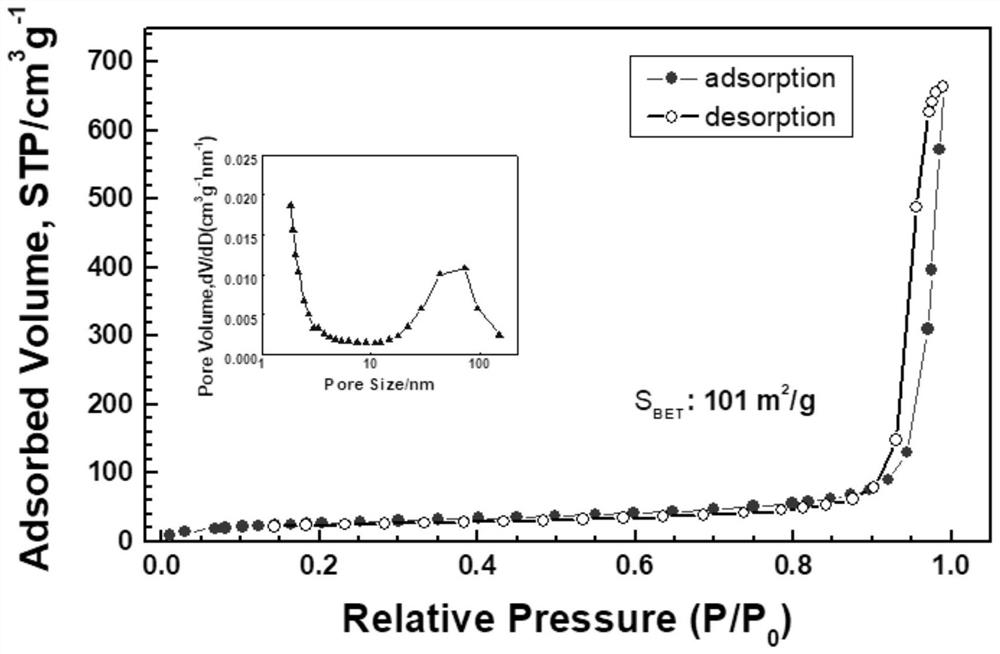

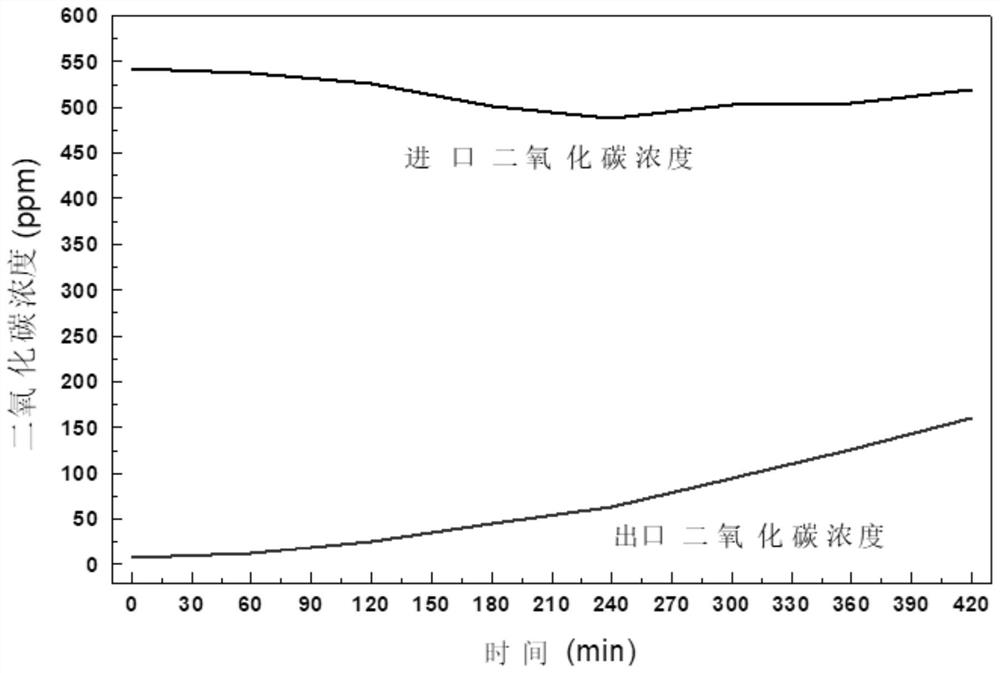

[0036] CO produced in this example 2 -SOR...

Embodiment 2

[0049] 400g diethanolamine is dissolved in 2.5kg ethanol and forms amine solution (mass fraction is 16%), adds 500g ordered mesoporous silica nanoporous carrier in amine solution, makes ordered mesoporous silica nanoporous carrier slow Slowly settle into the amine solution, mix evenly after settling to form a homogeneous mixture;

[0050] Add 75g of polymethacrylate with a molecular weight of 5000 to the mixture, stir at room temperature, make diethanolamine, ordered mesoporous silica nanoporous carrier and polymethacrylate undergo crosslinking reaction for more than 5min, then add 30g Glycine, stirred until a gel-like product is formed;

[0051] The product was dried at room temperature for 72 hours, shaped into columnar particles, and then dried in an oven at 50°C for 10 hours to obtain a renewable nanoporous adsorption material for removing carbon dioxide (referred to as CO2 for short). 2 -SORBENT-2).

[0052] CO produced in this example 2 -SORBENT-2 was tested as follow...

Embodiment 3

[0065] 400g triethylenetetramine is dissolved in 2.5kg chloroform to form amine solution (mass fraction is 16%), in amine solution, add 500g porous carbon particle nanoporous carrier, make porous carbon particle nanoporous carrier slowly settle down to In the amine solution, mix well after settling to form a homogeneous mixture;

[0066] Add 30g of polyacrylate with a molecular weight of 6000 to the mixture, stir at room temperature, make triethylenetetramine, porous carbon particle nanoporous carrier and polyacrylate undergo crosslinking reaction for more than 5min, then add 14g of aminopiperazine, stir , until a gel-like product is formed;

[0067] The product was dried at room temperature for 8 hours, shaped into columnar particles, and then dried in an oven at 150°C for 1 hour to obtain a renewable nanoporous adsorption material for removing carbon dioxide (referred to as CO2 for short). 2 -SORBENT-3).

[0068] CO produced in this example 2 -SORBENT-3 was tested as foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com