Silicone rubber foaming sealing material and preparation method thereof

A foamed sealing material and silicone rubber technology, applied in the field of silicone rubber materials, can solve the problems of compressive stress relaxation, compression permanent deformation, low mechanical properties, etc., and achieve the effects of less smoke and increased reactive cross-linking points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

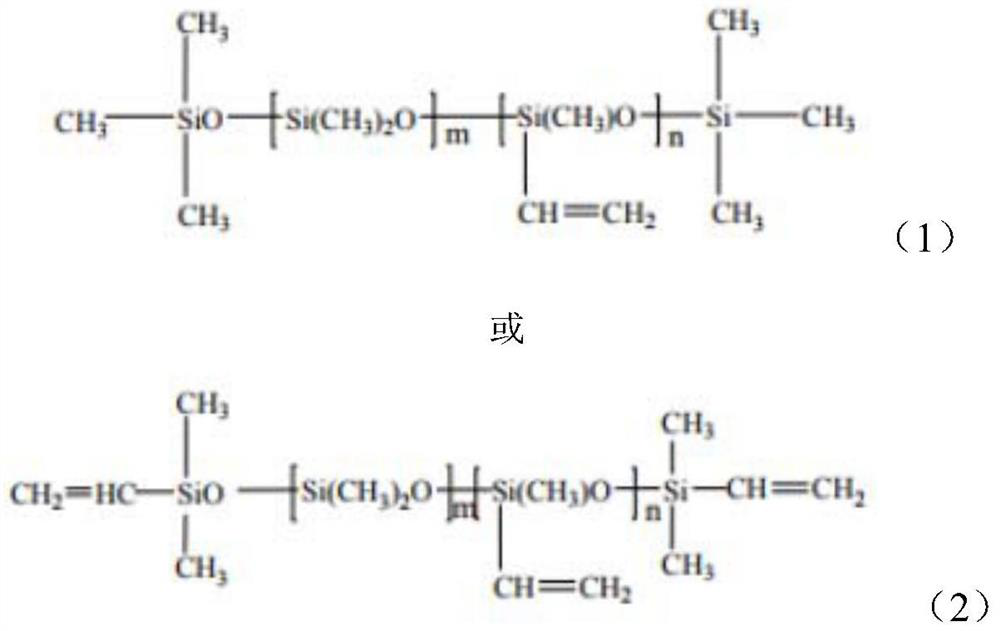

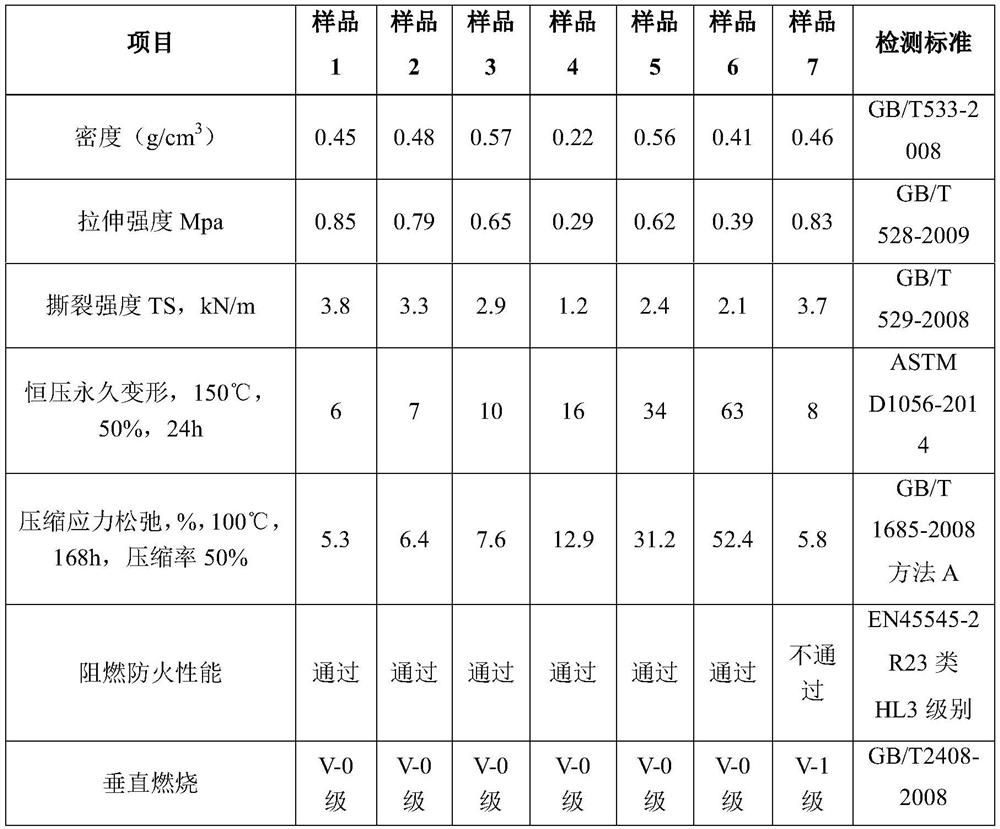

[0037]A silicone rubber foam sealing material, mainly prepared from the following raw materials in parts by weight: methyl vinyl silicone rubber (vinyl content 0.06%, molecular weight 500,000, hardness 50 Shore A) 100g, structural formula ( 1) 4g of vinyl silicone oil (viscosity of 10,000mPa·s, vinyl content of 8.5%), vinyl MQ silicone resin (viscosity of 5000mPa·s, vinyl content of 2.4%) 3g, flame retardant filler 40g (cyanide Uric acid melamine salt 30g, aluminum hydroxide 10g), 5000ppm platinum flame retardant 0.8g, azobisisobutyronitrile 3.5g, composite vulcanizing agent 1.76g (including PMBP 0.8g, odorless DCP 0.8g, TAIC 0.16g).

[0038] The preparation method of the silicone rubber foam sealing material of the present embodiment may further comprise the steps:

[0039] (1) Methyl vinyl silicone rubber (vinyl content 0.06%, molecular weight 500,000, hardness 50 Shore A) 100g, vinyl silicone oil (viscosity 10,000 mPa·s, ethylene Base content is 8.5%) 4g, vinyl MQ silicone...

Embodiment 2

[0044] A silicone rubber foam sealing material, mainly prepared from the following raw materials in parts by weight: 100 g of methyl vinyl silicone rubber (vinyl content 0.05%, molecular weight 400,000, hardness 60 Shore A), structural formula ( 2) 4g of vinyl silicone oil (viscosity of 15,000mPa·s, vinyl content of 5%), vinyl MQ silicone resin (viscosity of 8000mPa·s, vinyl content of 2.1%) 3g, flame retardant filler aluminum hydroxide 60g, 5000ppm platinum flame retardant 1.0g, azobisisobutyronitrile 3g, composite vulcanizing agent 1.76g (including PMBP 1g, odorless DCP 0.4g, TAIC 0.08g).

[0045] A preparation method of silicone rubber foam sealing material, comprising the following steps:

[0046] (1) Methyl vinyl silicone rubber (vinyl content 0.05%, molecular weight 400,000, hardness 60 Shore A) 100g, vinyl silicone oil with structural formula (2) (viscosity 15,000 mPa·s, vinyl Content is 5%) 4g, vinyl MQ silicone resin (viscosity 8000mPa·s, vinyl content 2.1%) 3g, flam...

Embodiment 3

[0051] Replace 30 g of flame-retardant filler melamine cyanurate and 10 g of aluminum hydroxide with 60 g of flame-retardant filler melamine cyanurate and 30 g of aluminum hydroxide. The content and preparation method of other components are the same as in Example 1 to obtain sample 3.

[0052] The performance test results of sample 3 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com