Full-biodegradable thermoplastic water-soluble film based on vinasse waste as well as preparation method and application of full-biodegradable thermoplastic water-soluble film

A technology of waste and water-soluble film, which is applied in the field of fully biodegradable thermoplastic water-soluble film and its preparation, can solve the problems of non-conformity with sustainable green development, limit the application of polyvinyl alcohol film, and long production cycle, and achieve excellent industrial Operability, improving production and processing efficiency and production output, and the effect of low carbon footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

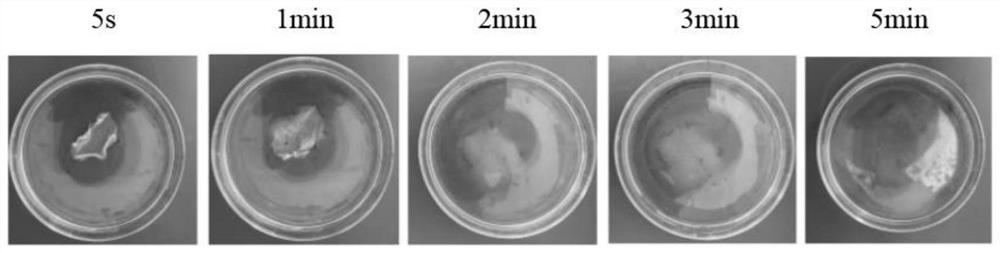

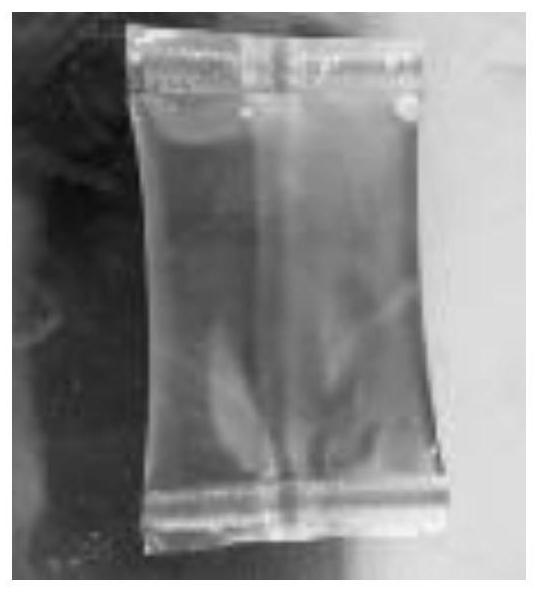

Method used

Image

Examples

Embodiment 1

[0039] The preparation process of the fully degradable thermoplastic water-soluble film in this embodiment is as follows:

[0040] (1) Modification of distiller's grain protein

[0041] Precipitate distiller's grain protein after protein extraction, separation and purification, place it in a stainless steel reaction kettle, add water to dilute to a suspension with a solid content of about 20-25wt%, and then use 0.5mol / L sodium hydroxide solution to dissolve the entire suspension system Adjust the pH to about 10, control the heating temperature to 90°C, and finally add 25%wt epoxy grafting agent relative to the absolute dry mass of distiller's grain protein, specifically propylene oxide, set the stirring speed to 200r / min, and the reaction time is 2h Simultaneously realize the salinization regulation and epoxy grafting modification of distiller's grain protein.

[0042] After the reaction, the pH of the distiller's grain protein suspension is adjusted to neutral, and the solid...

Embodiment 2

[0048] The difference from Example 1 is that the modified protein used is C12-C14 alkyl glycidyl ether modified distiller's grain protein.

Embodiment 3

[0050] The difference from Example 1 is that the modified protein used is n-butyl glycidyl ether modified distiller's grains.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com