Cathode photoelectrochemical detection model of T4 polynucleotide kinase and application of cathode photoelectrochemical detection model

A polynucleotide and photoelectrochemical technology, which is applied in the field of detection models for cathodic photoelectrochemical detection of T4 polynucleotide kinases, can solve the problems of interference, low biological reaction recognition efficiency, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] (1) Bi 2 o 3 Preparation of nanomaterials: 0.2-0.5g soluble bismuth salt (Bi(NO 3 ) 3 ·5H 2 O or bismuth sulfate) was dissolved in 60 mL of deionized water, then 0.5-0.9 g of trisodium citrate, 0.24 g of urea and 0.50-1.0 g of polyvinylpyrrolidone were added and vigorously stirred for 20-50 minutes; subsequently, the resulting mixed solution was transferred to Put it in a high-pressure reactor and react at 100-180°C for 5-12 hours; after cooling to room temperature, wash the obtained sample with ethanol and deionized water several times, and finally dry the sample at 60°C overnight to obtain basic carbonic acid Bismuth powder; finally, the obtained bismuth subcarbonate was heated in a muffle furnace at 350-450°C for 2 hours to obtain Bi 2 o 3 Powder samples of nanomaterials;

[0046] (2) Bi 2 o 3 / ITO electrode preparation: the Bi 2 o 3 The nanomaterials were dispersed in deionized water to make a suspension; then the resulting suspension was drop-coated on th...

Embodiment 1

[0051] A cathodic photoelectrochemical detection model of T4 polynucleotide kinase, its construction method comprises the steps:

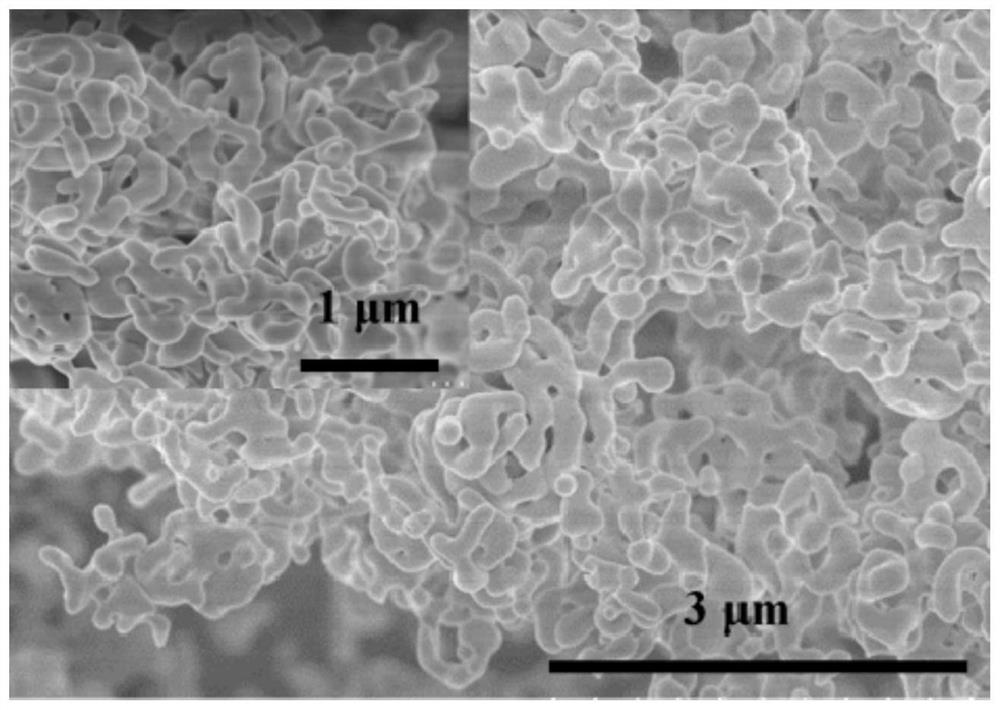

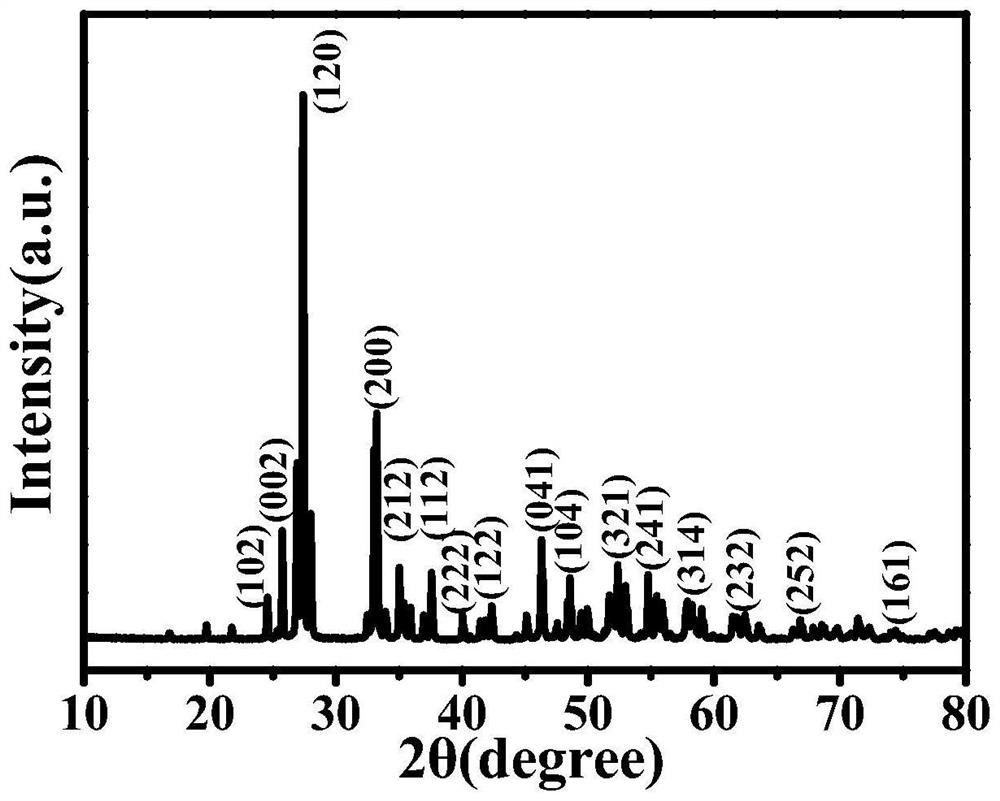

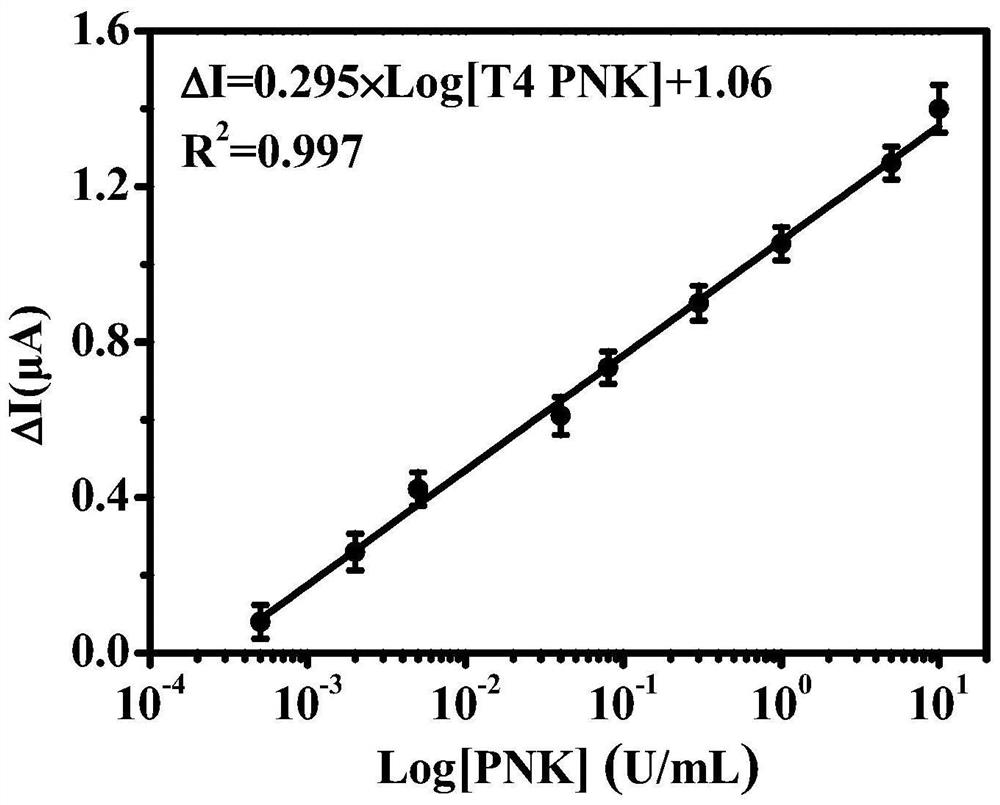

[0052] a. Bi 2 o 3 Preparation of nanomaterials: Weigh 0.48g bismuth nitrate and dissolve it in 60mL deionized water, then add 0.88g trisodium citrate, 0.24g urea and 0.50g polyvinylpyrrolidone and stir vigorously for 30 minutes; subsequently, transfer the obtained mixed solution Put it in a high-pressure reactor, and react at 180° C. for 12 hours. After cooling to room temperature, the obtained sample was washed several times with ethanol and deionized water, and the final sample was dried overnight at 60°C to obtain bismuth subcarbonate powder; finally, the obtained bismuth subcarbonate was heated in a muffle furnace at 400°C Heated for 2 hours to obtain Bi 2 o3 Powder samples of nanomaterials; e.g. figure 1 shown above Bi 2 o 3 SEM images of nanomaterials; such as figure 2 shown above Bi 2 o 3 X-ray diffraction patterns of nanomaterial...

Embodiment 2

[0060] A cathodic photoelectrochemical detection model of T4 polynucleotide kinase, its construction method comprises the steps:

[0061] a. Bi 2 o 3 Preparation: 0.35 g of bismuth sulfate was dissolved in 60 mL of deionized water, then 0.88 g of trisodium citrate, 0.24 g of urea, and 1.0 g of polyvinylpyrrolidone were added and vigorously stirred for 30 minutes; subsequently, the resulting mixed solution was transferred to a high-pressure reaction In the kettle, react at 160°C for 10 hours; after cooling to room temperature, the obtained sample is washed several times with ethanol and deionized water, and the final sample is dried overnight at 60°C to obtain bismuth subcarbonate powder; finally, the obtained The bismuth subcarbonate was heated in a muffle furnace at 400°C for 2 hours to obtain Bi 2 o 3 Powder samples of nanomaterials;

[0062] b. Bi 2 o 3 / ITO electrode preparation: the prepared Bi 2 o 3 Nanomaterials were added to deionized water, and a 1.0 mg / mL sus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com