CNTs/Fe3O4/melamine composite carbon foam as well as preparation method and application thereof

A technology of melamine carbon and melamine, applied in the field of wave absorbing materials, can solve the problem of easy agglomeration of particles and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

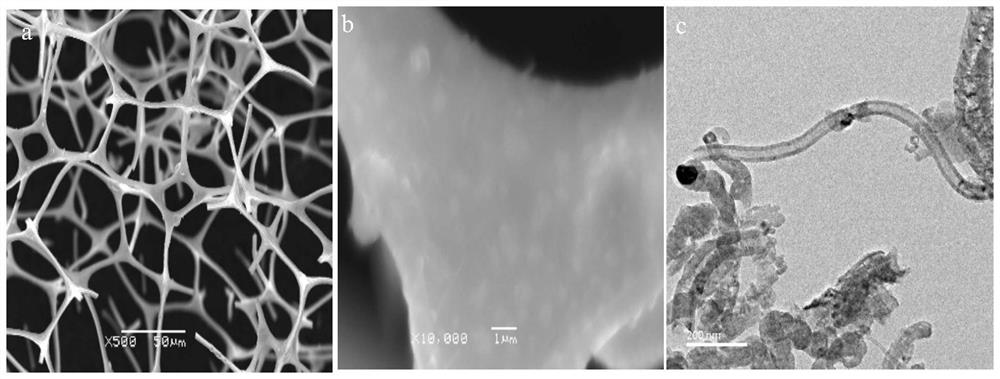

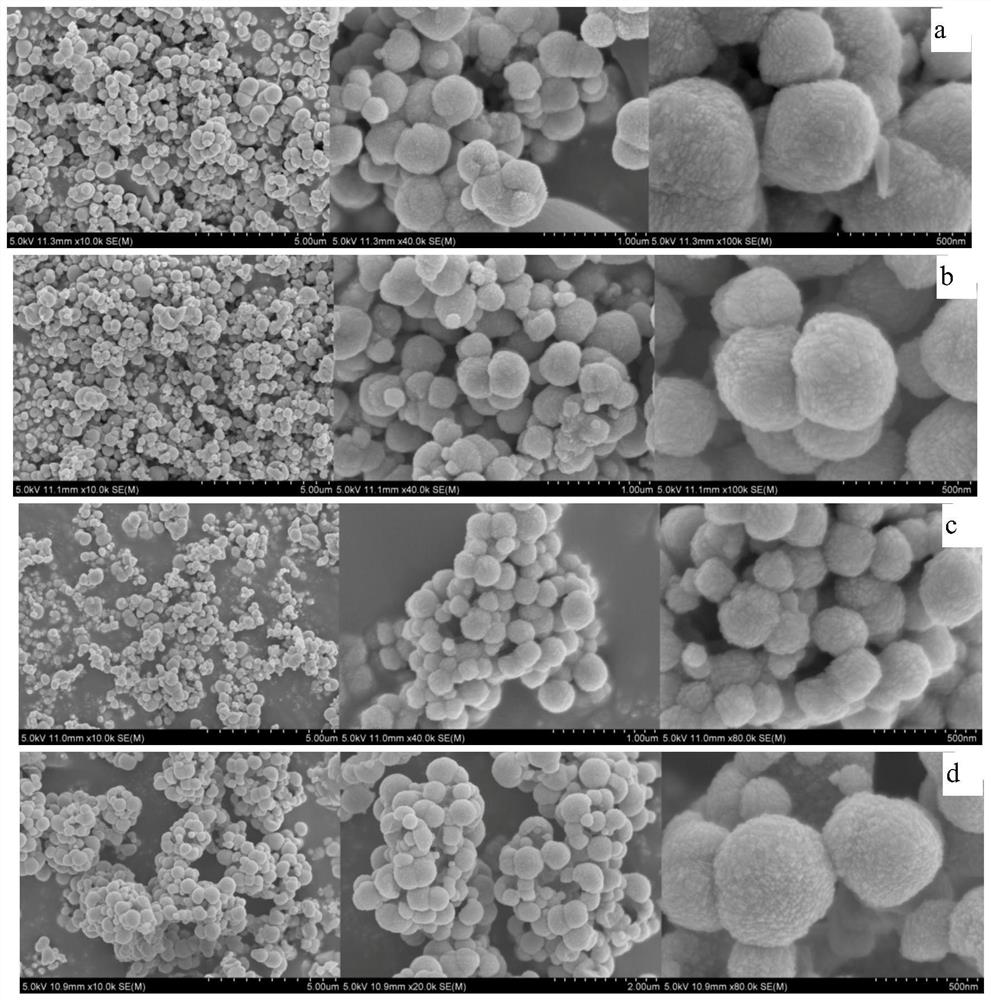

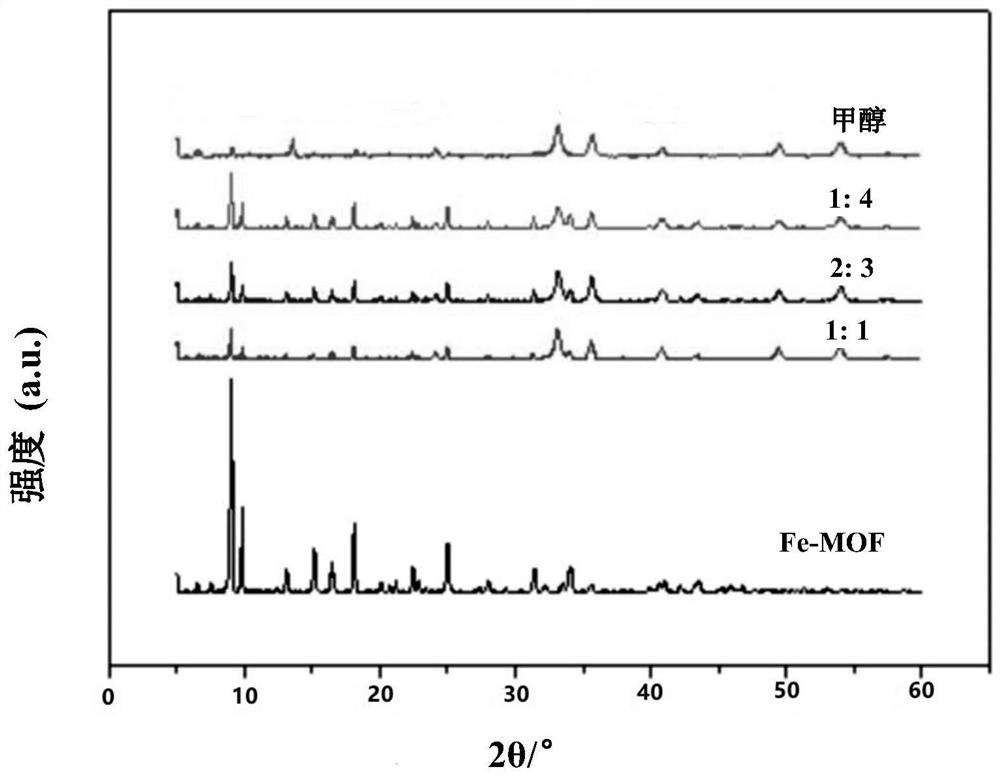

[0096] A CNTs / Fe 3 o 4 The preparation method of melamine composite carbon foam comprises the following steps:

[0097] 1. Cut the melamine sponge into cuboids whose length, width and thickness are 90mm, 28mm and 20mm, respectively. Soak the cut sample in ethanol solution for 30 minutes and ultrasonically vibrate, wash it repeatedly three times, and wash off the attached impurities before use. Place the pre-washed melamine sponge in a quartz dish, then move it into a tube furnace, and place it in high-purity N 2 Under the protection of , the temperature was raised to 700 ° C at a rate of 2 ° C / min, and then the carbonization process was carried out in a tube furnace at a constant temperature for 2 h. After the reaction was completed, wait for the tube furnace to cool down to room temperature naturally, take out the carbon foam and ultrasonically wash it with ethanol solution for 30 minutes, and obtain the melamine-based carbon foam after drying.

[0098] 2. Weigh the fer...

Embodiment 2

[0105] A CNTs / Fe 3 o 4 The preparation method of melamine composite carbon foam comprises the following steps:

[0106] 1. Cut the melamine sponge into cuboids whose length, width and thickness are 90mm, 28mm and 20mm, respectively. Soak the cut sample in ethanol solution for 30 minutes and ultrasonically vibrate, wash it repeatedly three times, and wash off the attached impurities before use. Place the pre-washed melamine sponge in a quartz dish, then move it into a tube furnace, and place it in high-purity N 2 Under the protection of , the temperature was raised to 800 °C at a rate of 2 °C / min, and then the carbonization process was carried out in a tube furnace at a constant temperature for 2 h. After the reaction was completed, wait for the tube furnace to cool down to room temperature naturally, take out the carbon foam and ultrasonically wash it with ethanol solution for 30 minutes, and obtain the melamine-based carbon foam after drying.

[0107] 2. Weigh the ferroce...

Embodiment 3

[0114] A CNTs / Fe 3 o 4 The preparation method of melamine composite carbon foam comprises the following steps:

[0115] 1. Cut the melamine sponge into cuboids whose length, width and thickness are 90mm, 28mm and 20mm, respectively. Soak the cut sample in ethanol solution for 30 minutes and ultrasonically vibrate, wash it repeatedly three times, and wash off the attached impurities before use. Place the pre-washed melamine sponge in a quartz dish, then move it into a tube furnace, and place it in high-purity N 2 Under the protection of , the temperature was raised to 850 °C at a rate of 2 °C / min, and then the carbonization process was carried out in a tube furnace at a constant temperature for 2 h. After the reaction was completed, wait for the tube furnace to cool down to room temperature naturally, take out the carbon foam and ultrasonically wash it with ethanol solution for 30 minutes, and obtain the melamine-based carbon foam after drying.

[0116] 2. Weigh the ferroce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com