Sludge micro-positive pressure carbonization control system and gas purification method

A control system and gas purification technology, applied in chemical instruments and methods, separation methods, greenhouse gas capture, etc., can solve the problem of high mineralization degree of sludge carbonization products, easy access of sludge carbonization system to air, and availability of sludge carbon Low degree and other problems, to achieve the effect of improving the utilization rate of sensible heat, reducing the content, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a sludge micro positive pressure carbonization control system and a gas purification method.

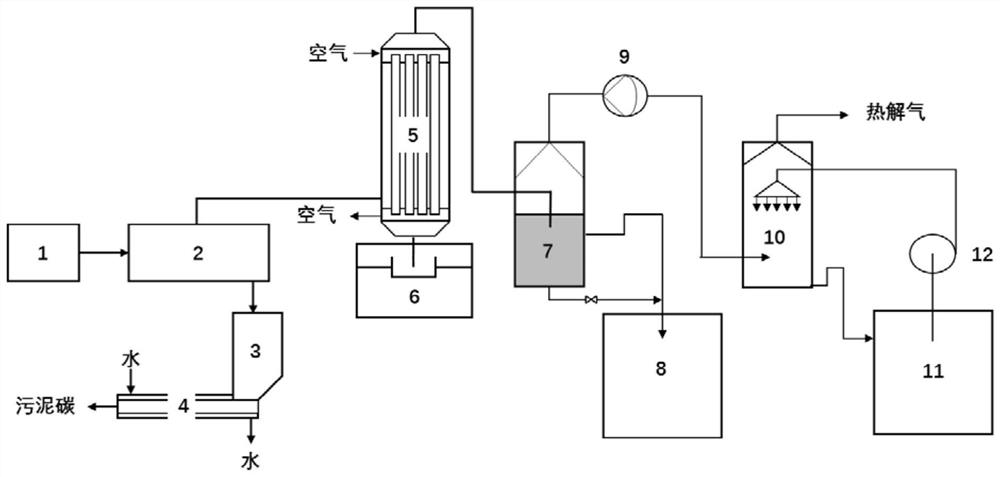

[0046] figure 1 A schematic diagram of a micro positive pressure carbonization control system for sludge according to an embodiment of the present invention is shown.

[0047] Such as figure 1 As shown, the sludge micro-positive pressure carbonization control system includes: sludge low-temperature drying device 1, sludge carbonization furnace 2, finished material sealing bin 3, water-cooled screw discharger 4, decoking cooler 5, tar collector 6 , Submerged pressure-controlled cleaner 7, cleaning agent storage tank 8, diaphragm pump 9, leaching tower 10, eluent circulation pool 11, circulating water pump 12;

[0048] Sludge low-temperature drying device 1 is used for low-temperature drying of sludge; finished material sealing bin 3 is used to hold the discharge of sludge carbonization furnace 2; water-cooled screw discharger 4 is connected with finis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com