Preparation method of isoviolanthrone

A technology of isoxanthrone and benzoxanthone, which is applied in the field of preparation of isoxanthrone, can solve problems such as increased production cost, unfriendly environment, environmental pollution, etc., and achieves avoiding waste of raw materials, reducing production cost, and reducing disposal volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

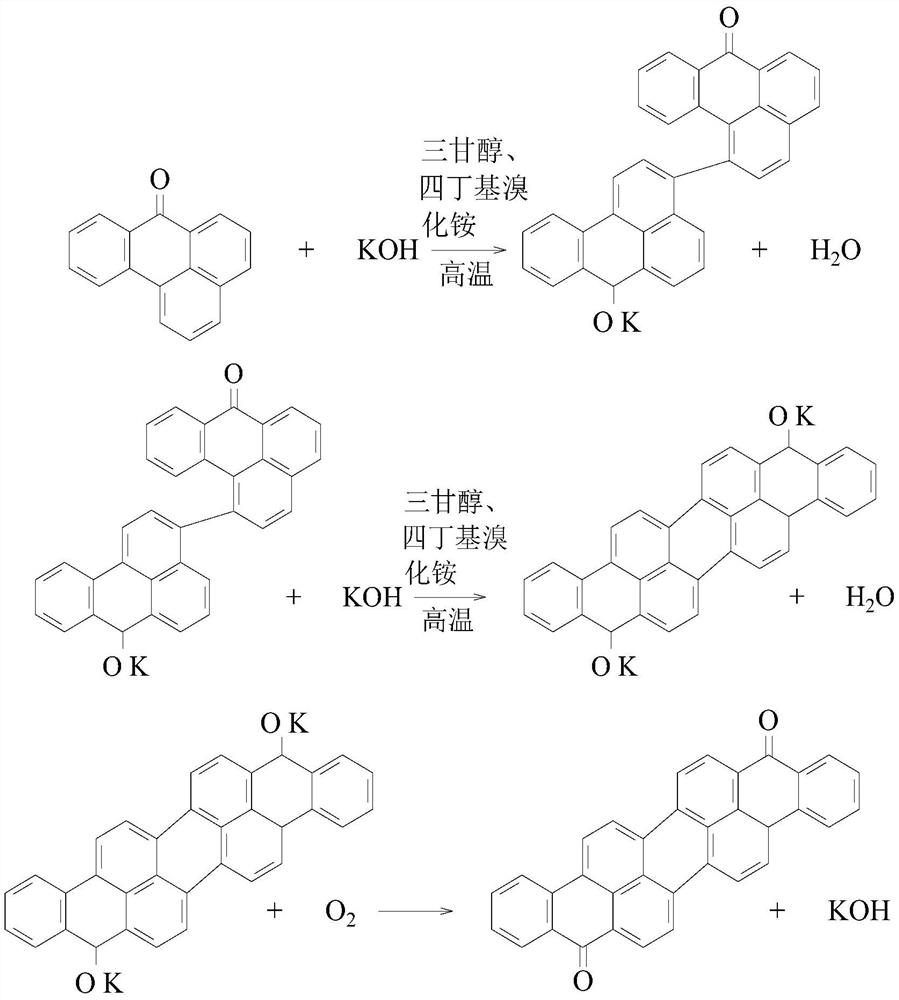

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Add 120g of potassium hydroxide, 80g of triethylene glycol, and 0.6g of tetrabutylammonium bromide into the reaction flask and mix evenly, then raise the temperature to 170-190°C, and keep it warm for 1h, so as to make the mixture more full and obtain a mixed solution; Then divide 60g of benzothrone evenly into 24 times, and add benzoxanthone each time when the temperature of the mixed solution drops to 170° C. During the ketone process, the compressed air with a pressure of 0.025MPa was always fed, and then the heat preservation was continued for 3 hours. After the heat preservation was completed, the compressed air was stopped and cooled naturally to 50-100°C to obtain 133ml of reaction materials, which were placed in 700ml Stir and dilute in water for 3 hours at a stirring speed of 700rpm, and then obtain 0.8L of mother liquor and solid material through filtration; the solid material is dried at 105-125°C after washing to obtain 59.5g of isoviolanthrone; th...

Embodiment 2

[0027] Example 2: Add 600g of potassium hydroxide, 600g of triethylene glycol and 3g of tetrabutylammonium bromide into the reaction flask and mix evenly, then raise the temperature to 170-190°C, keep it warm for 1h, the purpose is to make the mixture more full, and obtain a mixed solution; then Divide 60g of benzoxantrone evenly into 12 times, and add benzoxantrone each time when the temperature of the mixed solution drops to 170°C, so as to avoid adding too much at one time and causing the solution to become viscous and unable to fully react. During the process, the compressed air with a pressure of 0.025MPa has been introduced, and then the heat preservation is continued for 3h. After the heat preservation is completed, the compressed air is stopped and cooled naturally to 50-100°C to obtain 800ml of reaction materials, which are placed in a 3000ml Stir and dilute in water for 5 hours at a stirring speed of 500rpm, and then filter to obtain 3.4L of mother liquor and solid ma...

Embodiment 3

[0029] Example 3: Add 360g of potassium hydroxide, 60g of triethylene glycol, and 1.8g of tetrabutylammonium bromide into the reaction flask and mix evenly, then raise the temperature to 170-190°C and keep it warm for 1h to make the mixture more filling and obtain a mixed solution; Then divide 60g of benzothrone evenly into 30 times, and add benzoxanthone each time when the temperature of the mixed solution drops to 170°C, so as to avoid adding too much at one time to cause the solution to be viscous and then unable to fully react. During the ketone process, the compressed air with a pressure of 0.025MPa was continuously fed, and then the heat preservation was continued for 3 hours. After the heat preservation was completed, the compressed air was stopped and cooled naturally to 50-100°C to obtain 120ml of reaction materials, which were placed in 2400ml Stir and dilute in water for 30min at a stirring speed of 700rpm, and then obtain 2.4L of mother liquor and solid material by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com